Preparation method for cobalt-loaded ordered mesoporous carbon material and application of cobalt-loaded ordered mesoporous carbon material in process of catalyzing oxone to degrade rhodamine B in wastewater

A mesoporous carbon and cobalt-loaded technology, applied in other chemical processes, chemical instruments and methods, oxidized water/sewage treatment, etc., can solve problems such as ecological environment and human health hazards, achieve high removal efficiency, large removal capacity, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

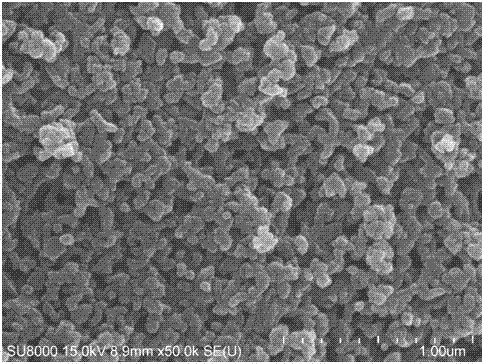

Embodiment 1

[0021] (1) Add 0.22g of resorcinol, 0.12g of melamine and 0.32g of formaldehyde into 20mL of deionized water and dissolve them by stirring. After completely dissolving to form a uniform solution, continue stirring for 0.5h to obtain solution A. Add 0.36g of F127 (EO 106 PO 70 EO 106 , Pluronic F127) particles were added to 40mL deionized water, stirred until completely dissolved to obtain solution B, solution B was added to solution A, mixed and stirred for 2 hours, the mixed solution was placed in a hydrothermal reaction kettle for hydrothermal reaction at 130°C After cooling to room temperature for 10 hours, the product was left to stand and separated, and was centrifuged and washed three times with deionized water and ethanol respectively to obtain pink melamine-phenolic resin balls, which were then dried at 60°C, ground, and then dried under anaerobic conditions for 4 The heating rate of ℃ / min was raised to 700 ℃ and roasted for 2 hours to obtain the mesoporous carbon sup...

Embodiment 2

[0025] At room temperature, when 5 mL of Oxone solution with a molar concentration of 0.01 mol / L was added to 100 mL of Rhodamine B wastewater with a mass concentration of 25 mg / L, the degradation efficiency was 99.46% in 3 hours and the degradation rate could eventually reach 100%.

Embodiment 3

[0027] (1) Add 0.22g of resorcinol, 0.12g of melamine and 0.32g of formaldehyde into 20mL of deionized water and dissolve them by stirring. After completely dissolving to form a uniform solution, continue stirring for 0.5h to obtain solution A. Add 0.36g of F127 (EO 106 PO 70 EO 106 , Pluronic F127) particles were added to 40mL deionized water, stirred until completely dissolved to obtain solution B, solution B was added to solution A, mixed and stirred for 2 hours, the mixed solution was placed in a hydrothermal reaction kettle for hydrothermal reaction at 130°C After cooling to room temperature for 10 hours, the product was left to stand and separated, and was centrifuged and washed three times with deionized water and ethanol respectively to obtain pink melamine-phenolic resin balls, which were then dried at 60°C, ground, and then dried under anaerobic conditions for 4 The heating rate of ℃ / min was raised to 700 ℃ and roasted for 2 hours to obtain the mesoporous carbon sup...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com