Environmental-protection cleaning device and process method for separating organic azeotropes

A technology for cleaning devices and azeotropes, applied in separation methods, distillation separation, chemical instruments and methods, etc., can solve problems such as environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

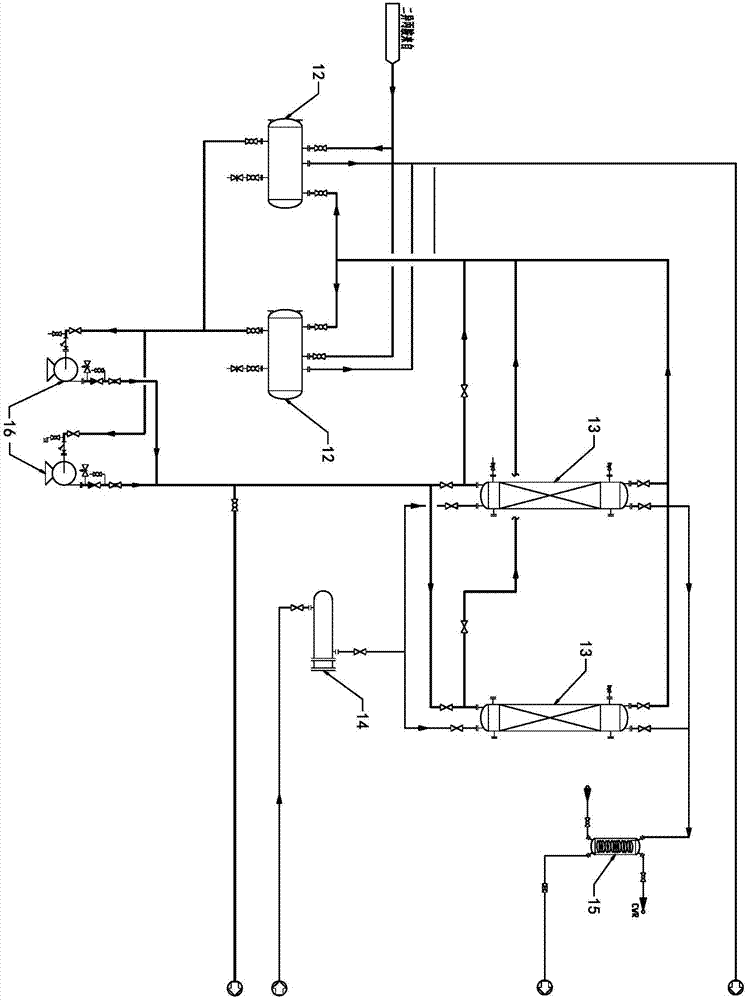

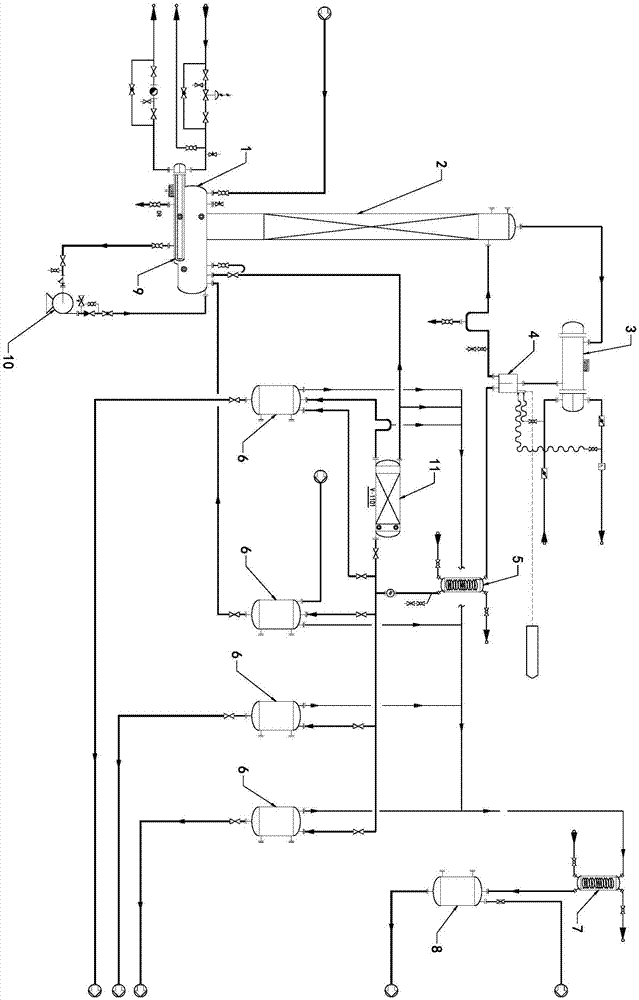

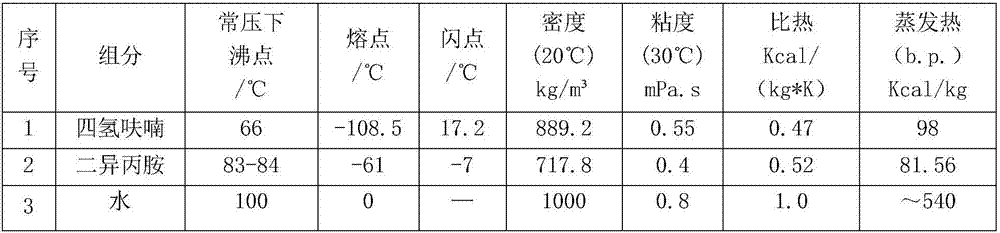

[0025] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0026] Such as figure 1 As shown, an environmentally friendly cleaning device for separating organic azeotropes includes a rectification unit, and the rectification unit includes a rectification kettle 1, a rectification tower 2, a condenser 3, a reflux ratio distributor 4, and a first cooler 5 , separation receiving tank 6, tail cooler 7, tail cooler tank 8; the rectification still 1 is arranged at the lower end of the rectification tower 2, the inside of the rectification still 1 is provided with a first heater 9, and the rectification still 1 The rectification tower 2 is communicated; the rectification tower 2 top is communicated with the condenser 3 inlet; the condenser 3 outlet is communicated with the reflux r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com