A kind of method for preparing environment-friendly naphthenic rubber oil

A naphthenic rubber oil, environment-friendly technology, applied in the treatment of hydrocarbon oil, petroleum industry, hydrotreating process, etc., can solve the problem of unavailability of extracts containing polycyclic aromatic hydrocarbons, low utilization rate of naphthenic raw materials, and poor Aromatic oil is not effectively utilized and other problems, to achieve the effect of low aromatic content, low cost and high utilization rate of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

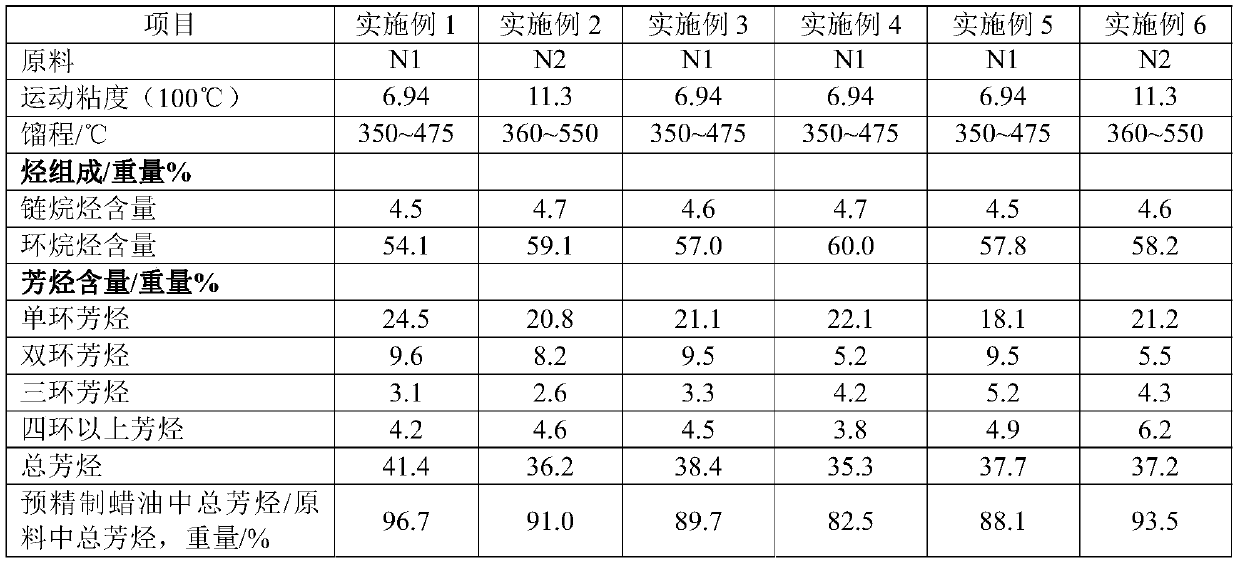

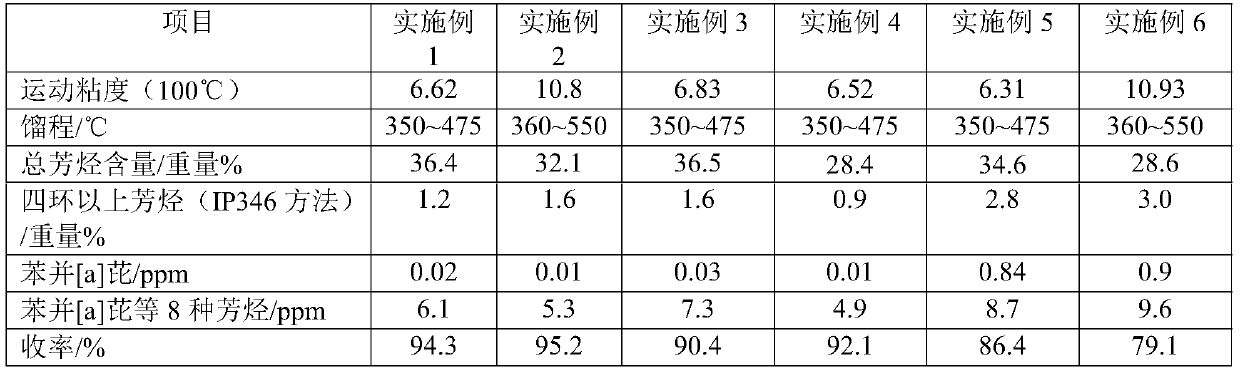

Examples

Embodiment approach

[0045] Specific implementation of hydrogenation pre-refining treatment conditions 1: Hydrogen partial pressure is 12.0MPa, reaction temperature is 360°C, and feed space velocity is 0.8h -1 , The volume ratio of hydrogen to oil is 400:1.

[0046] Specific implementation method 2 of hydrogenation pre-refining treatment conditions: hydrogen partial pressure is 14.0MPa, reaction temperature is 340°C, and feed space velocity is 1.0h -1 , The volume ratio of hydrogen to oil is 360:1.

[0047] Specific implementation method 3 of hydrogenation pre-refining treatment conditions: hydrogen partial pressure is 16.0MPa, reaction temperature is 320°C, and feed space velocity is 1.2h -1 , The volume ratio of hydrogen to oil is 240:1.

[0048] Preferably, the freezing point of the naphthenic vacuum wax oil is <25°C, and the wax content is ≤5% by weight; more preferably, the freezing point of the naphthenic vacuum wax oil is <20°C, and the wax content is ≤3 % by weight, total aromatics cont...

specific Embodiment approach 2

[0051] Specific implementation mode 2 of naphthenic vacuum wax oil: the distillation range of the naphthenic vacuum wax oil of the present invention is 350-520°C, the freezing point is -8°C, the wax content is <3% by weight, and the total aromatics content is was 39%.

[0052] Specific implementation mode 3 of naphthenic vacuum wax oil: the distillation range of the naphthenic vacuum wax oil of the present invention is 373~568°C, the freezing point is 7°C, the wax content<5% by weight, and the total aromatic content is 54%.

[0053] Preferably, in step 2), the conditions of the vacuum stripping are controlled so that the flash point of the obtained degassed hydrogenated wax oil is above 200°C. The stripping medium of the vacuum stripping can be superheated steam.

[0054] Preferably, in step 3), the conditions of the solvent extraction and separation are controlled so that the dry weight of the extracted liquid is 1 to 12% by weight of the degassed hydrogenated wax oil; more...

Embodiment approach 1

[0061] Preferred embodiment 1: The extracted liquid obtained in step 3) is subjected to solvent removal treatment to obtain extracted oil, and the extracted oil is used as an asphalt improver for blending asphalt and the like.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com