Method for preparing major biomass platform compounds from sub/super critical methanol liquified cellulose

A technology of supercritical methanol and cellulose, which is applied in the preparation of liquid hydrocarbon mixtures, the petroleum industry, and the treatment of hydrocarbon oils. It can solve problems that need to be further explored, and achieve the effects of strong practicality, mild reaction conditions, and economical prices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

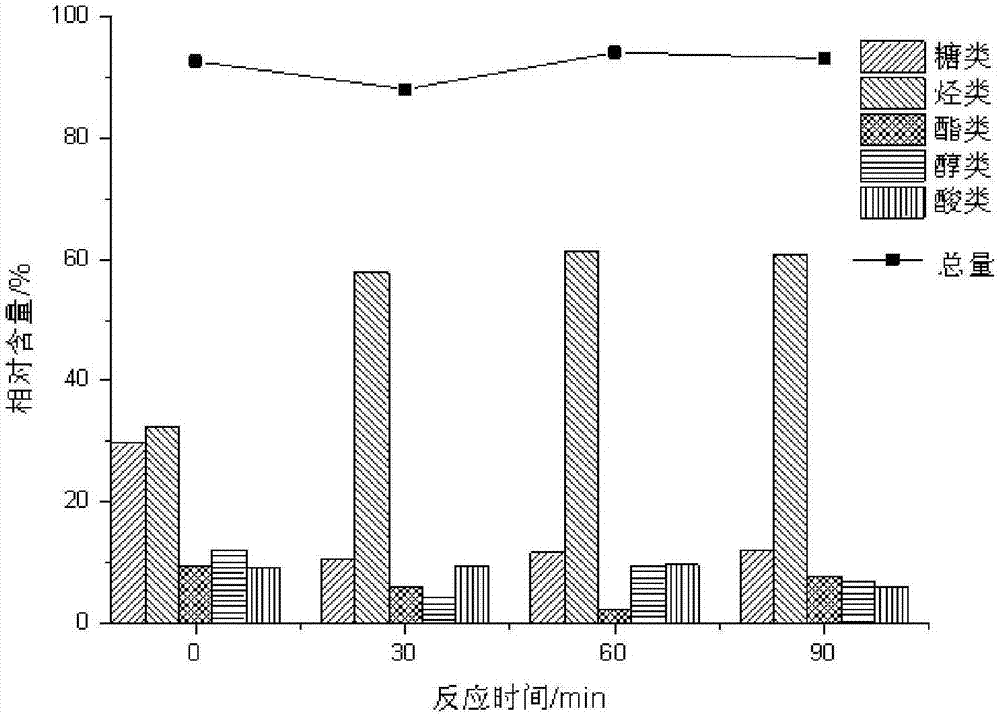

[0036] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the embodiments do not limit the present invention in any form. Unless otherwise specified, the reagents, methods and equipment used in the present invention are conventional reagents, methods and equipment in this technical field. Unless otherwise specified, the reagents and materials used in the present invention are commercially available. The impact of embodiment 1 methanol consumption on the yield of main biomass platform compounds

[0037]1. Preparation of straw-like cellulose: Accurately weigh 30g of straw powder, refer to the relevant methods in the national standard GB / T 2677.1-93 ~ GB / T 2677.10-95, and pre-extract with ethanol-benzene (volume ratio: 2:1) , to remove fat-soluble substances; and then stir the straw powder with distilled water at 70-80°C for 2 hours to remove water-soluble substances such as polysaccharides and starch...

Embodiment 2

[0044] The influence of embodiment 2 reaction temperature on the yield of main biomass platform compound

[0045] 1. Method

[0046] Add 8g of dried cellulose powder and 160mL of methanol into a 1L batch autoclave with a magnetic stirrer, sealed and heated to 240°C to 320°C. ℃, and keep the reaction at this temperature for 60 min. Cool to room temperature and collect the product. Cool to room temperature and collect the product. The product collection method is the same as in Example 1. The product yield is calculated on the basis of dividing the mass of the product obtained by the mass of the raw material after removing the ash.

[0047] 2. The yield statistics of the main biomass platform compounds generated by the liquefaction of straw cellulose at a methanol dosage of 160mL, a reaction time of 60min, and a reaction temperature distribution of 240°C, 260°C, 280°C, 300°C, and 320°C were carried out. Calculated to obtain the relative content of the main biomass platform ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| critical temperature | aaaaa | aaaaa |

| critical pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com