Drilling fluid

A technology of drilling fluid and alkyl glycoside, applied in the field of drilling fluid, can solve the problems of loss, unachievable performance, unfavorable drilling operations, etc., and achieve the effect of low cost and good inhibition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] In the present invention, the preparation method of the cationic alkyl glycoside having the structure of formula I preferably comprises the following steps:

[0046] (A1) Under the action of a catalyst, hydrolyze the chlorinated alkyl epoxide and water to obtain a hydrolyzate;

[0047] (A2) reacting the hydrolyzate with an alkyl glycoside to obtain a chlorohydrin glycoside;

[0048] (A3) reacting the chlorohydrin glycoside with a tertiary amine to obtain a cationic alkyl glycoside.

[0049] In the present invention, the catalyst is preferably an acidic catalyst, which may be one or more of organic acids and inorganic acids. In the present invention, the organic acid is preferably a sulfonic acid compound, more preferably toluenesulfonic acid, dodecylbenzenesulfonic acid or sulfamic acid. In the present invention, the inorganic acid is preferably sulfuric acid, nitric acid or phosphoric acid. The present invention has no special limitation on the specific type of the ...

Embodiment 1

[0107] Add 0.2 mol of epichlorohydrin, 2.4 mol of distilled water and 0.004 mol of p-toluenesulfonic acid into a high-pressure reactor equipped with a thermometer, condenser, and stirrer, and react under normal pressure at 60°C for 3 hours to obtain 3-chloro - 1-2-propanediol aqueous solution;

[0108] Cool the 3-chloro-1-2-propanediol aqueous solution to normal temperature, add 0.4 mol of methyl glucoside to it, and react at normal pressure 80°C for 0.5 hours to obtain a chlorohydrin glycoside solution;

[0109] The chlorohydrin glucoside solution was neutralized with a saturated aqueous sodium hydroxide solution to a pH value of 7, and then 0.04 moL of a 33.3% trimethylamine aqueous solution was added to the bottom of the chlorohydrin glycoside solution, and the addition was completed within 1 hour , reacted at 40° C. for 3 hours to obtain cationic methyl glucoside, and the yield of the product was 95.25%.

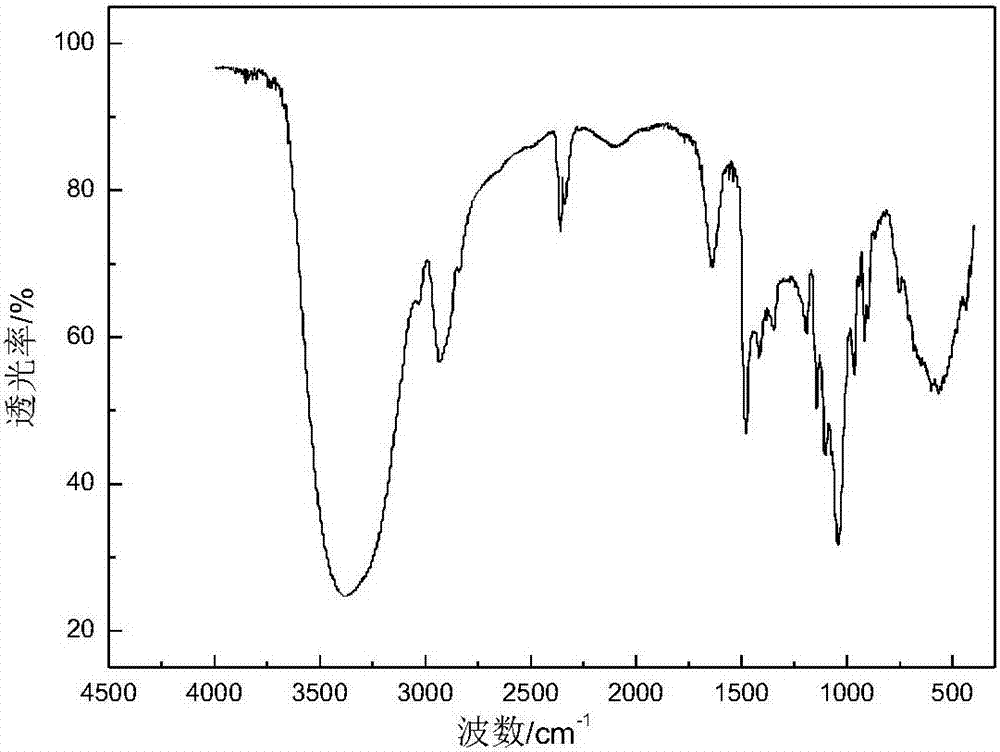

[0110] The cationic methyl glucoside prepared in Example 1 of the ...

Embodiment 2

[0112] Add 0.2 mol of epichlorohydrin, 3.2 mol of distilled water and 0.014 mol of p-sulfamic acid into a high-pressure reactor equipped with a thermometer, condenser, and stirrer, and react under normal pressure at 80°C for 6 hours to obtain 3-chlorohydrin - 1-2-propanediol aqueous solution;

[0113] Cool the 3-chloro-1-2-propanediol aqueous solution to normal temperature, add 0.22 moL ethyl glucoside to it, and react at normal pressure 90°C for 3 hours to obtain a chlorohydrin glycoside solution;

[0114] The chlorohydrin glycoside solution was neutralized with saturated potassium hydroxide aqueous solution to a pH value of 7, and then 0.2 moL trimethylamine aqueous solution was added to the bottom of the chlorohydrin glycoside solution, and the addition was completed within 1 hour. After reacting for 7 hours, cationic ethyl glucoside was obtained, and the yield of the product was 93.57%.

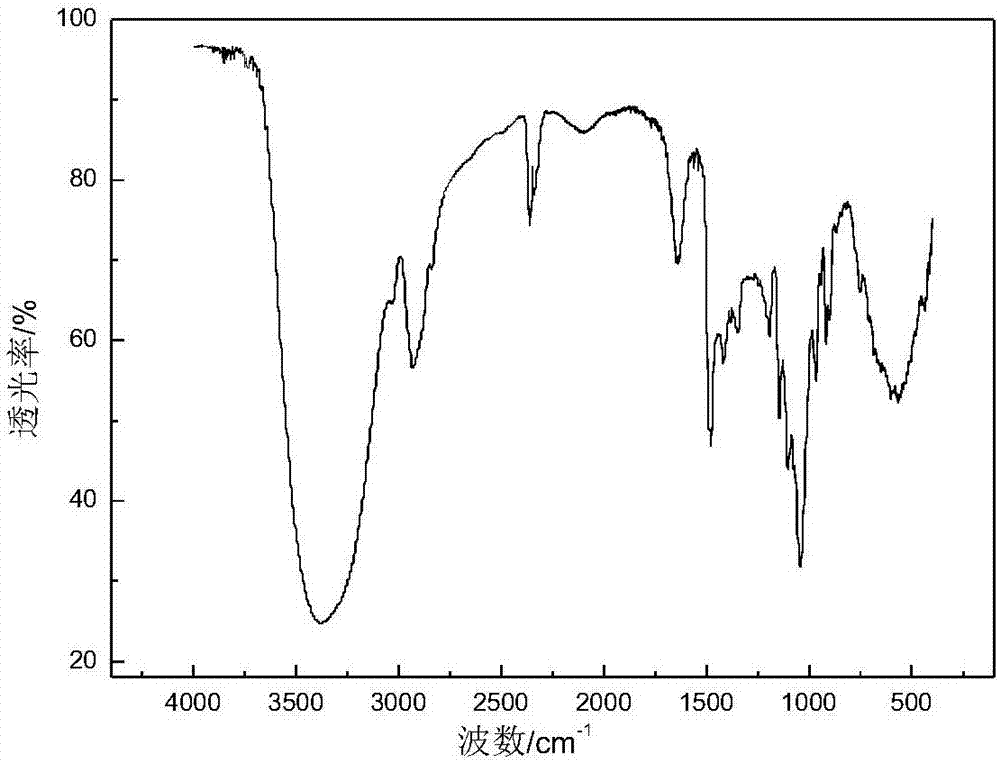

[0115] The cationic ethyl glucoside prepared in Example 2 of the present invention i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com