Anticorrosive paint used in waste gas treatment equipment and preparation method thereof

A technology for waste gas treatment equipment and anti-corrosion coatings, applied in anti-corrosion coatings, coatings and other directions, can solve the problems of large influence of paint film temperature and humidity, high requirements on anti-corrosion substrate treatment, long curing time, etc., to achieve good hiding power, excellent Effects of storage stability, excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

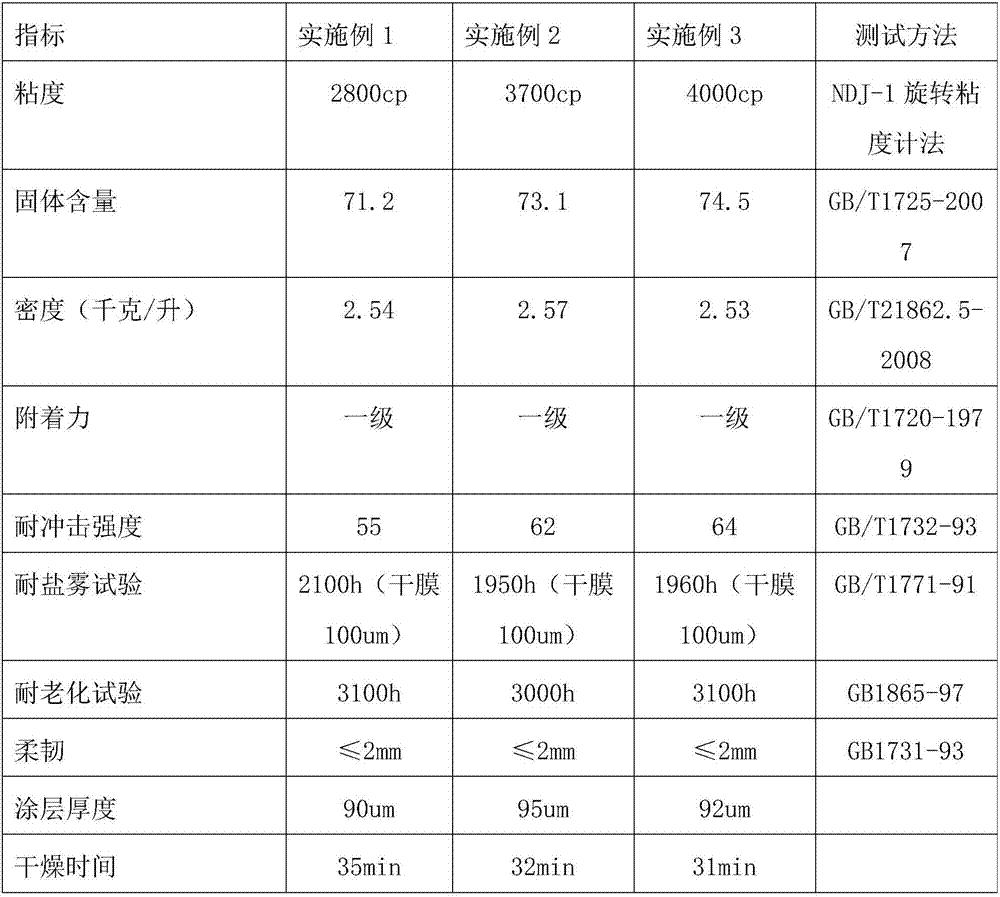

Examples

Embodiment 1

[0029] An anti-corrosion coating for exhaust gas treatment equipment, including the following raw materials: 18kg of acrylic acid, 12kg of butyl acetate, 4kg of N-methylpyrrolidone, 3kg of VAE emulsion, 2kg of polyoxyethylene lauryl ether, 1kg of acetone, and palygorskite 1kg, lithium bentonite 1kg, nano silica gel 1kg, nano titanium dioxide 1kg, ethylene glycol monomethyl ether 1kg, polyurethane 14kg, graphite 12kg, talcum powder 6kg, calcium acetylacetonate 0.7kg, thickener 0.2kg, leveling agent 0.1kg , phenolic antioxidant 0.6kg and compatibilizer 0.4kg.

[0030] The anti-corrosion coating for exhaust gas treatment equipment also includes nano-active calcium carbonate weighing 11kg.

[0031] The thickener is organic bentonite.

[0032] The leveling agent is polydimethylsiloxane.

[0033] The phenolic antioxidant is 1,3,5-tris(4-tert-butyl-3-hydroxy-2,6-dimethylbenzyl)-1,3,5-triazine-2,4,6 -(1H,3H,5H)-trione, 2,2'-methylene-bis-(4-ethyl-6-tert-butylphenol) and 2,2'-methyl...

Embodiment 2

[0042] An anti-corrosion coating for exhaust gas treatment equipment, including the following raw materials: 24kg of acrylic acid, 14kg of butyl acetate, 6kg of N-methylpyrrolidone, 4kg of VAE emulsion, 3kg of polyoxyethylene lauryl ether, 3kg of acetone, palygorskite 5kg, lithium-based bentonite 2kg, nano-silica gel 2kg, nano-titanium dioxide 3kg, ethylene glycol monomethyl ether 2kg, polyurethane 18kg, graphite 20kg, talcum powder 12kg, calcium acetylacetonate 0.9kg, thickener 0.4kg, leveling agent 0.3kg , phenolic antioxidant 0.8kg and compatibilizer 0.8kg.

[0043] The anti-corrosion coating for exhaust gas treatment equipment also includes nano-active calcium carbonate with a weight of 15kg.

[0044] The thickener is organic bentonite.

[0045] The leveling agent is polydimethylsiloxane.

[0046] The phenolic antioxidant is 2,2'-methylene-bis-(4-ethyl-6-tert-butylphenol).

[0047] The compatibilizer is an acrylic type compatibilizer.

[0048] A method for preparing an...

Embodiment 3

[0055] An anti-corrosion coating for exhaust gas treatment equipment, including the following raw materials: 21kg of acrylic acid, 13kg of butyl acetate, 5kg of N-methylpyrrolidone, 3.5kg of VAE emulsion, 2.5kg of polyoxyethylene lauryl ether, 2kg of acetone, and 3kg of gorgorite, 1.5kg of lithium bentonite, 1.5kg of nano silica gel, 2kg of nano titanium dioxide, 1.5kg of ethylene glycol monomethyl ether, 16kg of polyurethane, 16kg of graphite, 9kg of talc, 0.8kg of calcium acetylacetonate, 0.3kg of thickener, Leveling agent 0.2kg, phenolic antioxidant 0.7kg and compatibilizer 0.6kg.

[0056] The anti-corrosion coating for exhaust gas treatment equipment also includes nano-active calcium carbonate with a weight of 13kg.

[0057] The thickener is organic bentonite.

[0058] The leveling agent is polydimethylsiloxane.

[0059] The phenolic antioxidant is 2,2'-methylene-bis-(4-methyl-6-tert-butylphenol).

[0060] The compatibilizer is an acrylic type compatibilizer.

[0061] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com