Spraying-free high-impact PC alloy material with metallic luster and preparation method thereof

A technology of alloy materials and metallic luster, which is applied in the field of high-impact PC alloy materials and its preparation, can solve the problems of easy generation of flow marks, poor compatibility, and easy discoloration of molded products, and achieve the effect of improving the impact resistance of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

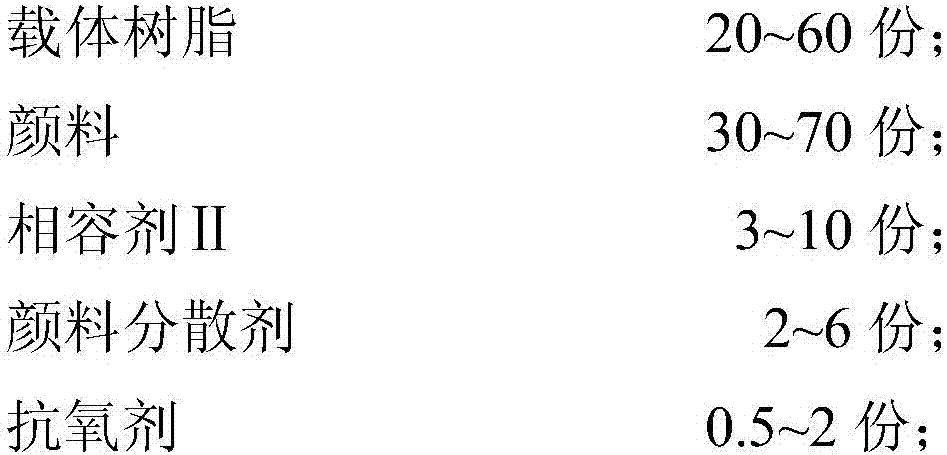

[0062] Preparation of pigment masterbatch:

[0063] Weigh each raw material component according to the corresponding data in Table 1 below (units are: gram), first stir the pigment and the pigment dispersant in a low-speed mixer at room temperature for 3 hours, let the pigment dispersant and the pigment act again, and add the pigment dispersant It helps the pigment to disperse more uniformly in the carrier resin and has better compatibility; then add the carrier resin, compatibilizer and antioxidant and stir at a low speed for 30 minutes, transfer to the twin-screw screw extruder, at 130-180 Extrusion and granulation at ℃ temperature, the length-to-diameter ratio of the extruder is 32, the shear is weak, and there are few kneading blocks, and various pigment masterbatches are prepared.

[0064] Table 1

[0065]

[0066] EMA resin is selected from DOW company brand 1125AC in the United States;

[0067] The pigment (pearl luster 1) is YZ323 (particle size 5-25um) selected f...

Embodiment 1~13

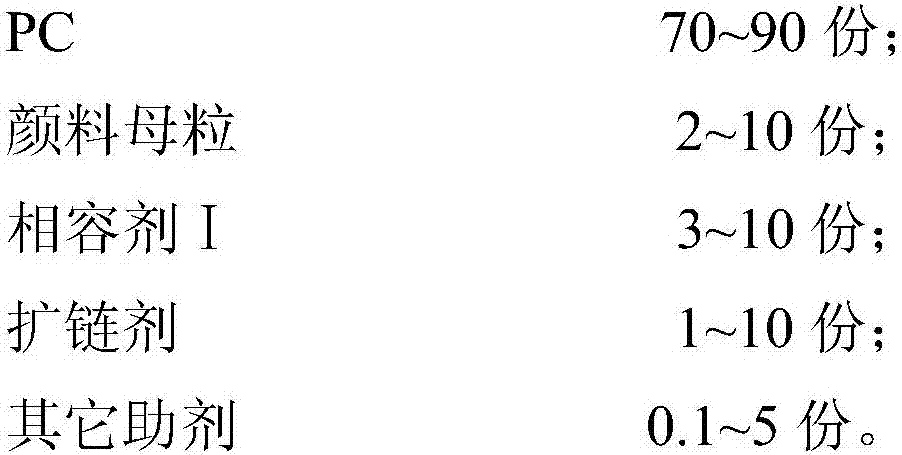

[0079] Embodiments 1-13 have the preparation of high-impact PC alloy material with metallic luster free from spraying

[0080] According to the corresponding example data in Table 2, weigh each raw material component (unit: kg), mix the other raw material components except the pigment masterbatch and compatibilizer I evenly, and send it to the main feed of the extruder , Pigment masterbatch and compatibilizer I are fed into the extruder through side feeding, mixed and plasticized at 220-260°C, the length-to-diameter ratio of the extruder is 36, the shear is weak, and there are few kneaded pieces, and then cooled The high-impact PC alloy material with metallic luster without spraying is prepared by pelletizing.

[0081] Table 2

[0082]

[0083]

[0084] The PC resin is injection molding grade PC resin of LG-DOW company brand 1201-10 and 1201-22;

[0085] Pigment (pearl 1) Zhejiang Wenzhou Yunzhu Pigment Factory YZ323 (particle size 5-25um);

[0086] Pigment (aluminum ...

Embodiment 1

[0103] Example 1 (PC pure resin) has the highest notched impact. And embodiment 2 (resin+pearl luster+antioxidant) and embodiment 6 (resin+aluminum strip+antioxidant) pearlescent pigment and aluminum strip pigment add and all cause material notched impact strength to drop significantly; Its reason is that PC and pearlescent or The poor compatibility of metallic pigments leads to a substantial decrease in the notch impact of the material.

[0104] In Examples 10-12, three kinds of purchased pigment masterbatches were respectively used, which were prefabricated color masterbatches coated and prefabricated by the purchased color masterbatch manufacturers. Compared with Example 2 and Example 6 in which pigments are directly added, the impact energy is improved by about 10%. The reason is that the dispersion of the pigment in the masterbatch is slightly better than that of the PC pure resin and the pearlescent pigment blended and extruded. In Example 13, PC resin is added with pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com