Preparation method of heavy metal adsorbent alpha-Al2O3 nanoparticles

A nanoparticle and adsorbent technology, which is applied in the field of nanoscale sewage treatment agent preparation, can solve the problems of alumina agglomeration, difficult control of particle size and shape, and difficult preparation and operation, and achieve low cost, high reaction selectivity, and high purity. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A. Dissolve 2g of aluminum powder into anhydrous ethylene glycol, control the molar ratio of aluminum powder and ethylene glycol to 1:25, stir on a temperature-controlled magnetic stirrer, add PEG6000, and control the mass ratio of PEG6000 to aluminum powder to be 0.035:1, temperature controlled stirring, adding AlCl 3 Catalyzed reaction, reacted at 65°C for 6 hours, and obtained white precipitate of aluminum ethylene glycol;

[0022] B. Add 25g of deionized water into the reaction vessel, temperature-controlled magnetic stirring, and hydrolyze at 60°C for 5 hours to form hydrated alumina gel;

[0023] C. Drying at 80°C for 24 hours, drying the hydrated alumina gel to form a xerogel;

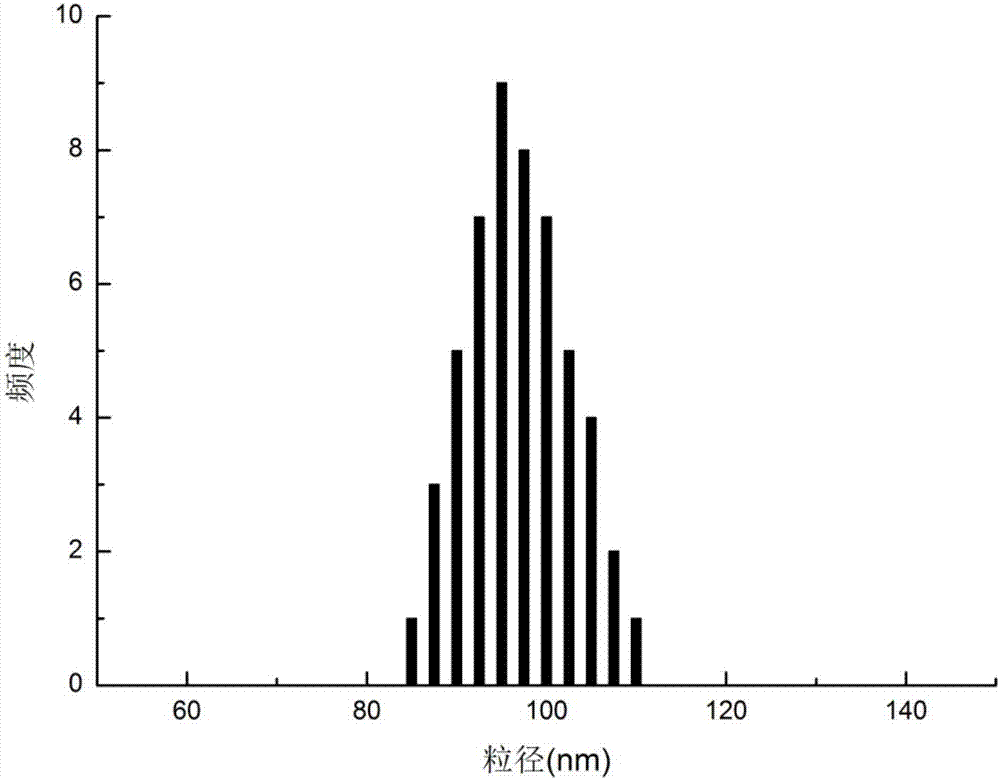

[0024] D. Calcining the dry gel at 10°C / min at a heating rate of 1100°C for 3 hours to prepare α-Al 2 o 3 Nanoparticles. The resulting α-Al 2 o 3 Nanoparticles are granular, with good dispersion and uniform particle size distribution.

Embodiment 2

[0026] A. Dissolve 2g of aluminum powder into anhydrous ethylene glycol, control the molar ratio of aluminum powder and ethylene glycol to 1:28, stir on a temperature-controlled magnetic stirrer, add PEG6000, and control the mass ratio of PEG6000 to aluminum powder to be 0.030:1, temperature controlled stirring, adding AlCl 3 Catalyzed reaction, reacted at 50°C for 8 hours, and obtained a white precipitate of aluminum ethylene glycol;

[0027] B. Add 25g of deionized water into the reaction vessel, temperature-controlled magnetic stirring, and hydrolyze at 65°C for 3 hours to form hydrated alumina gel;

[0028] C. Drying at 80°C for 24 hours, drying the hydrated alumina gel to form a xerogel;

[0029] D. Calcining xerogel at 8°C / min heating rate to 1150°C for 2.5h to prepare α-Al 2 o 3 Nanoparticles. The resulting α-Al 2 o 3 Nanoparticles are granular, with good dispersion and uniform particle size distribution.

Embodiment 3

[0031] A. Dissolve 2g of aluminum powder into anhydrous ethylene glycol, control the molar ratio of aluminum powder and ethylene glycol to 1:30, stir on a temperature-controlled magnetic stirrer, add PEG6000, and control the mass ratio of PEG6000 to aluminum powder to be 0.025:1, temperature controlled stirring, adding AlCl 3 Catalyzed reaction, reacted at 70°C for 5 hours, and obtained a white precipitate of aluminum ethylene glycol;

[0032] B. Add 25g of deionized water into the reaction vessel, temperature-controlled magnetic stirring, and hydrolyze at 70°C for 2 hours to form hydrated alumina gel;

[0033] C. Dry at 60°C for 48 hours, and dry the hydrated alumina gel to form a xerogel;

[0034] D. Calcining the xerogel at a heating rate of 5°C / min to 1200°C for 3 hours to prepare α-Al 2 o 3 Nanoparticles. The resulting α-Al 2 o 3 Nanoparticles are granular, with good dispersion and uniform particle size distribution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com