Process for the preparation and products of polyester-based rayon

A technology of artificial grass silk and polyester, which is applied in the direction of single-component polyester rayon, rayon manufacturing, textile and paper making, etc. Production, the effect of good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

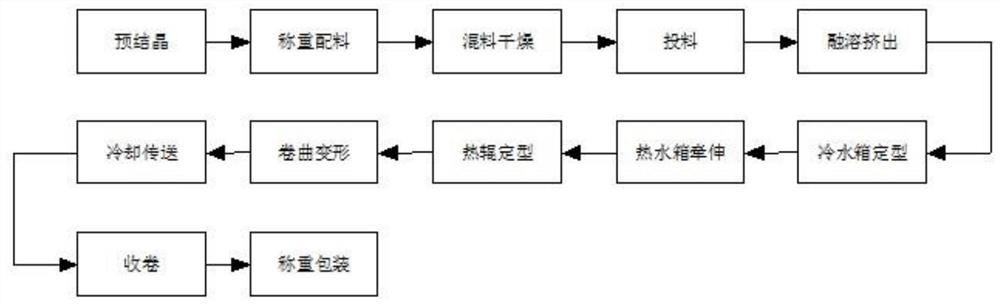

[0063] In a first embodiment of the present invention, the present invention provides a method for the preparation of polyester-based rayon (bend yarn), the resulting rayon and artificial turf or carpet based on the rayon. Its overall preparation process has, for example, image 3 The flowchart shown.

[0064] raw material

[0065] Suitable raw materials for use in the present invention are polyester based resin mixture raw materials. The mixture includes polyester and optional auxiliary agents (also called additives, auxiliary materials, etc.).

[0066] Polyester is generally a general term for polymers obtained by polycondensation of polyols and polyacids. As the polyester resin used in the polyester resin composition of the present invention, common thermoplastic polyester resins are used, and are not particularly limited. For example, polyalkylene terephthalates such as polyethylene terephthalate, polybutylene terephthalate, and polycyclohexanedimethylene terephthala...

no. 2 approach

[0102] In a second embodiment of the present invention, the present invention provides a method for the preparation of polyester-based rayon (straight yarn), the resulting rayon and artificial turf or carpet obtained based on the rayon. Its overall preparation process has, for example, Figure 4 The flowchart shown.

[0103] The process of pre-crystallization, weighing and batching, mixing and drying, feeding and melt extrusion, and cold water tank shaping of straight polyester artificial turf is basically the same as the process of bending (polyester) artificial turf in the above-mentioned first embodiment. Therefore, the selection of specific raw materials and the setting of equipment are performed with reference to the first embodiment.

[0104] When carrying out the straight yarn production of rayon, after carrying out cold setting (cold water tank setting), carry out the processing of following steps:

[0105] Preheating and dehumidification treatment

[0106] In som...

Embodiment 1

[0118] Polyester curved yarn, used for artificial turf flat blanket, production of 4400D / 8F polyester dyed yarn

[0119] Raw material ratio:

[0120] PET resin: SB500 100% (basic weight),

[0121] Polyester masterbatch 6%,

[0122] Processing aid 2%,

[0123] equipment:

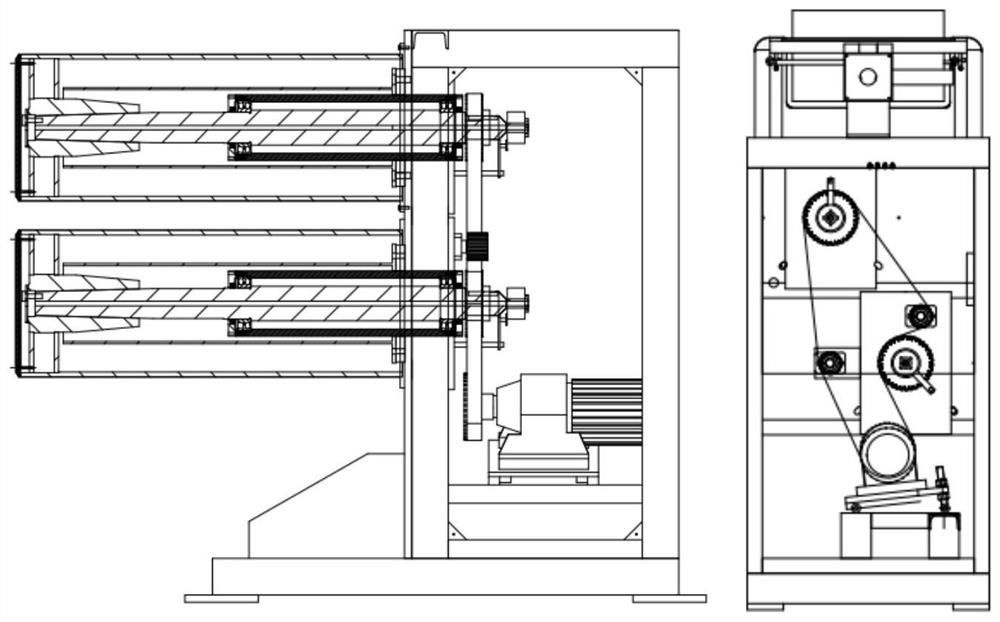

[0124] 1 pre-crystallization equipment, 2 screw dryers, 1 mixing hopper, and 1 FB10 polyester bending yarn production line;

[0125] Pre-crystallization steps for polyester:

[0126] 1) Put 500KG SB500 raw material into the pre-crystallization equipment, set the hot air temperature to 180°C, control the material temperature at 110°C, start the mixer, and pre-crystallize for 4 hours;

[0127] 2) Inhale the pre-crystallized raw material into the dryer, match it with 6% polyester color masterbatch, set the hot air temperature to 220°C, control the material temperature within 140°C, start the screw to stir and dry, and the drying time is 4 hours;

[0128] Mixing and feeding:

[0129] 1) Take out 100KG of r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com