Low-odor TPV material with sterilization function and preparation method thereof

A low-odor, functional technology, applied in the field of low-odor and sterilizing TPV materials and their preparation, can solve the problems of inability to completely remove low-volatile substances, slow escape of low-volatile substances, low TVOC content, etc. Improved catalytic performance, improved spectral response range, and less agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

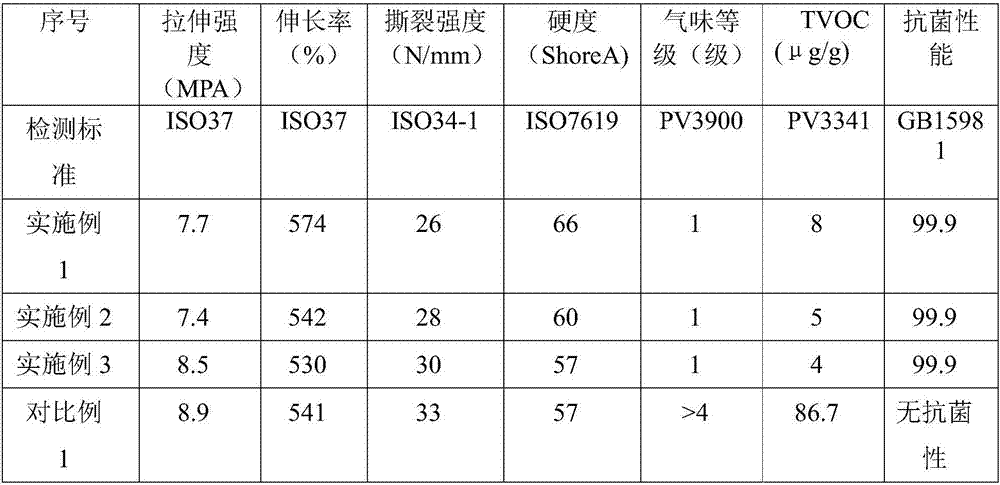

Examples

Embodiment 1

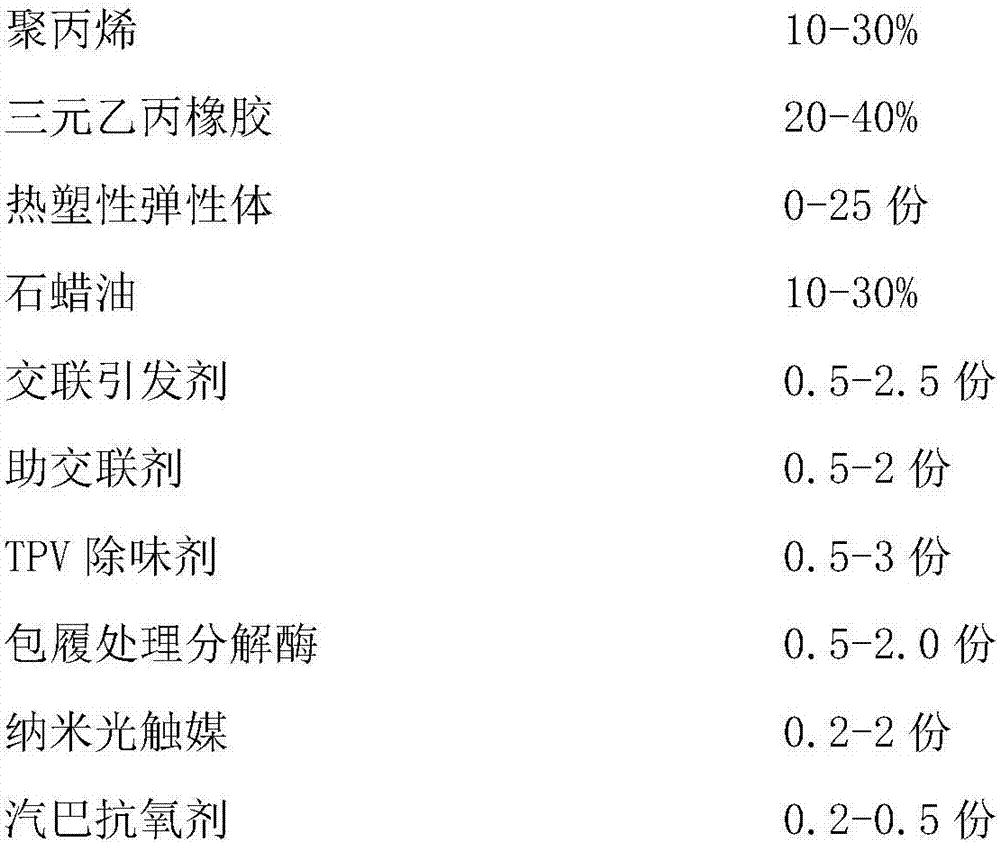

[0038] (1) First, 30 parts of polypropylene (Yangzi Petrochemical F401, homopolymer extrusion grade), 30 parts of EPDM rubber, 20 parts of paraffin oil, 21.69 parts of SEBS, 0.4 parts of Ciba antioxidant (IRGANOXB215, antioxidant Agent 1010 and antioxidant 168 in a mass ratio of 1:2), mixed and masticated at 150-180°C for 15 minutes, extruded and granulated to obtain a one-step TPV material. (2) 0.76 parts of crosslinking initiator 2,5-dimethyl-2,5-bis(tert-butylperoxy)hexane (also known as double two five), 1.55 parts of auxiliary crosslinking agent TMPTA, Mix 2.6 parts of TPV deodorant (LDV 1040 from Hefei Innovation Lightweight Material Co., Ltd.) together and mix evenly for use to obtain component A; treat the package with decomposing enzyme (purchased from Japan ECO Co., Ltd., model ECO-E) 0.6 parts and 0.4 parts of nano-photocatalyst (purchased from Longinus Co., Ltd., trade name LONGINUS, model KV-1N) were mixed uniformly and set aside to prepare component B. TPV deodo...

Embodiment 2

[0041] (1) First, add 30 parts of polypropylene, 35 parts of EPDM rubber, 25 parts of paraffin oil, 10.77 parts of SEBS, and 0.4 parts of Ciba antioxidant (Irganox1010 and Irganox168 are mixed in a mass ratio of 1:1), and then add In an internal mixer, mix and masticate at 150-180°C for 15 minutes, extrude and granulate to obtain a one-step TPV material.

[0042] (2) Mix 0.88 parts of cross-linking initiator Shuangerwu, 1.85 parts of cross-linking aid TMPTA, and 2.8 parts of TPV deodorant (LDV 1040) to prepare component A; (purchased from Japan ECO Co., Ltd., the model is ECO-E) 0.8 part, nano photocatalyst (purchased from Co., Ltd. Longinus, the trade name is LONGINUS, the model is KV-1N) 0.5 part are mixed together and stand-by, prepared Component B. TPV deodorant LDV 1040 is composed of a matrix and a low boiling point additive in a mass ratio of 1: (0.1-9); the matrix is a high-porosity polyolefin open-cell foam with a network structure of interpenetrating or closed por...

Embodiment 3

[0045] (1) First mix 30 parts of polypropylene, 40 parts of EPDM rubber, 30 parts of paraffin oil, 0.4 parts of Ciba antioxidant (IRGANOXB215, antioxidant 1010 and antioxidant 168 in a mass ratio of 1:2) ) into the internal mixer in turn, mixed and masticated at 150-180° C. for 15 minutes, extruded and granulated to obtain a one-step TPV material.

[0046] (2) Mix 1 part of cross-linking initiator Shuangerwu, 2 parts of cross-linking aid TMPTA, and 3 parts of TPV deodorant (LDV 1040) to prepare component A; From Japan ECO Co., Ltd., model is ECO-E) 1 part, nano-photocatalyst (purchased from Co., Ltd. Longinus, trade name is LONGINUS, model is KV-1N) 0.6 parts and mix together uniformly for use to obtain group B share. The TPV deodorant LDV 1040 is composed of a matrix and a low boiling point additive in a mass ratio of 1: (0.1-9); the matrix is of high porosity with interpenetrating or closed pores forming a network structure Polyolefin open-cell foam plastics; the low boi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com