Treatment equipment for ink printing waste gas

A waste gas treatment equipment and ink printing technology, applied in the direction of gas treatment, use of liquid separation agent, membrane technology, etc., can solve the problems that affect the standard requirements of waste gas treatment or the next process, poor demisting effect, high equipment cost, etc., and achieve resistance Small size, high processing efficiency, and the effect of ensuring discharge standards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

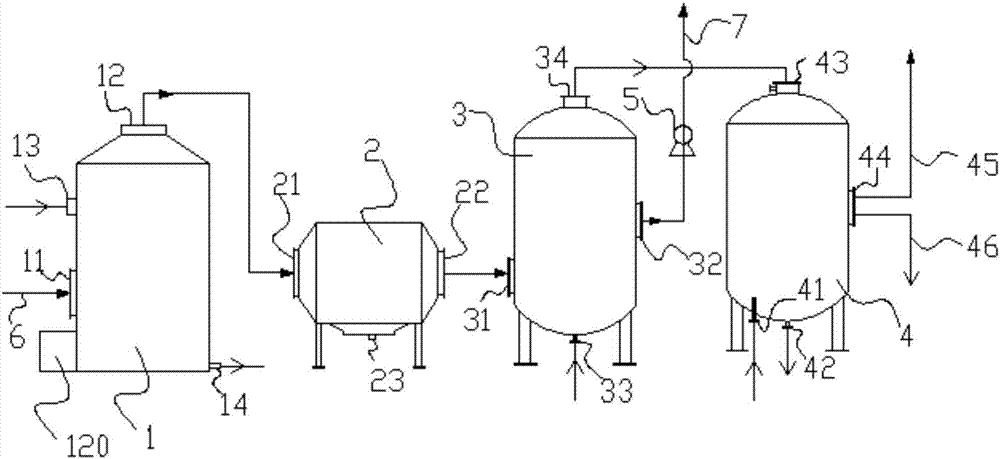

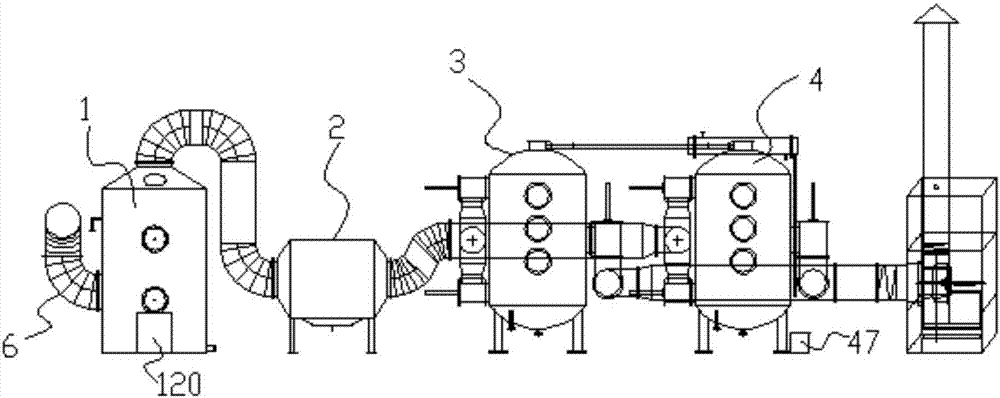

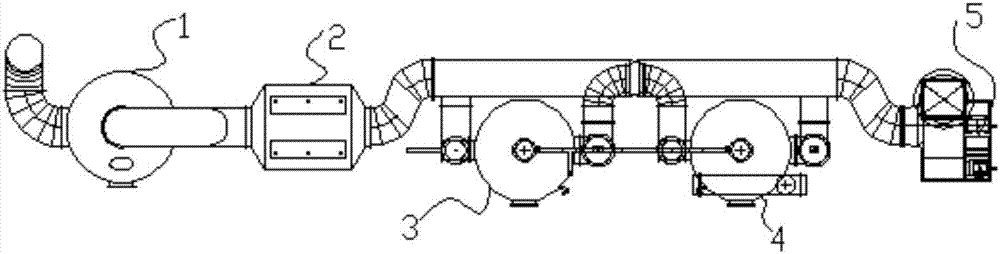

[0063] Embodiment: a kind of ink printing waste gas treatment equipment, such as Figure 1 to Figure 11 Shown, comprise water washing tower 1, defogging box 2, activated carbon adsorption desorption box 3, condenser 4 and main blower fan 5, described demisting box is positioned at the downstream of described water washing tower, and described activated carbon adsorption desorption box is positioned at the The downstream of the demister box, the condenser is located downstream of the demister box, and the main fan is located downstream of the activated carbon adsorption and desorption box;

[0064] The tower body of the water washing tower is provided with a first air inlet 11, a first air outlet 12, a first water inlet 13 and a first water outlet 14, and the casing of the demister box is provided with a second air inlet 21 , the second air outlet 22 and the second water outlet 23, the second water outlet is located at the bottom of the casing, the casing of the activated carbo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com