Nano-lamellar structure of Ni3S2/MoS2 composite material and preparation method thereof

A technology of nickel trisulfide and molybdenum disulfide, which is used in nanotechnology, structural parts, nanotechnology and other directions for materials and surface science, can solve the problems that cannot meet the requirements of large-scale practical application of low-temperature fuel cells, oxygen reduction reaction The catalytic properties are not good enough, and the catalytic properties of the oxygen reduction reaction are not good enough to achieve the effects of good resistance to methanol poisoning, abundant electrochemical active sites, and good catalytic stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Put 160mg of ammonium molybdate, 80mg of nickel chloride, 4g of template and 2g of thioacetamide into a mortar, mix and grind them, put the ground powder into a tube furnace, and pass through argon protection; then, put The burning temperature was raised to 600°C and maintained for 180 minutes, then raised to 780°C and maintained for 240 minutes; finally, the heating device was turned off, and it was taken out after it cooled naturally to room temperature.

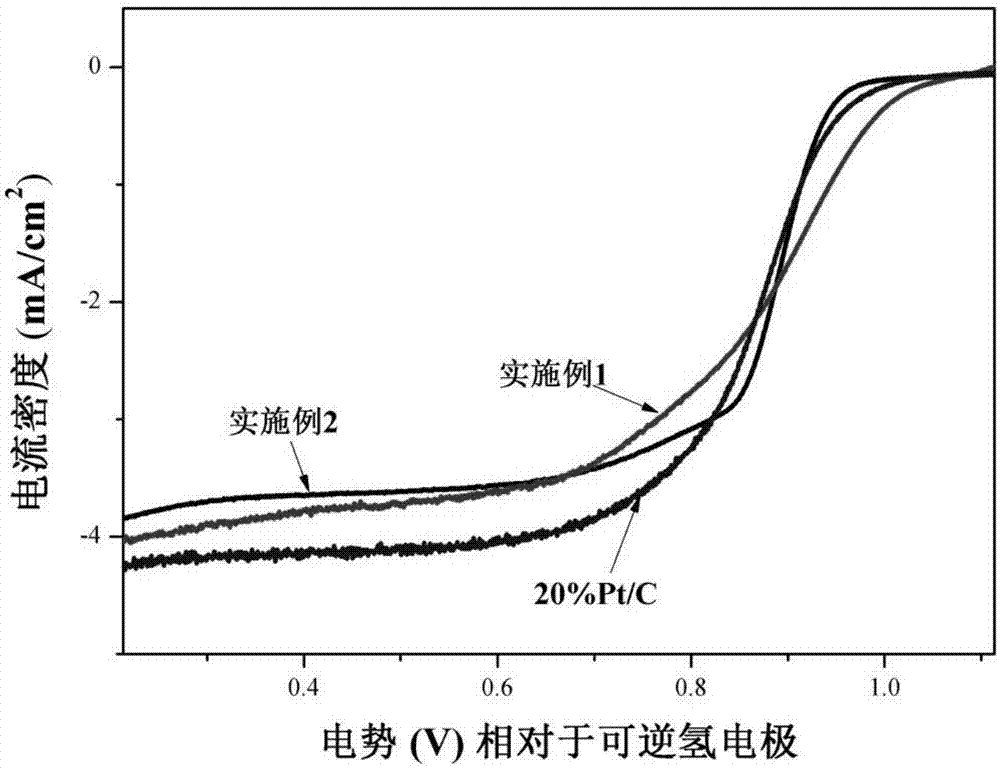

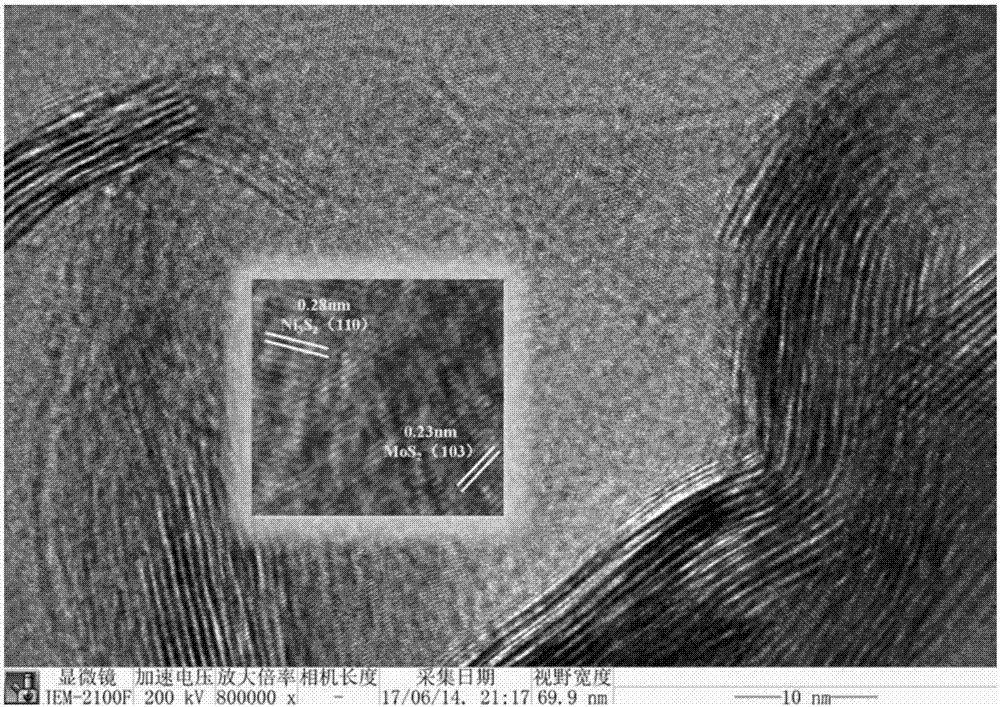

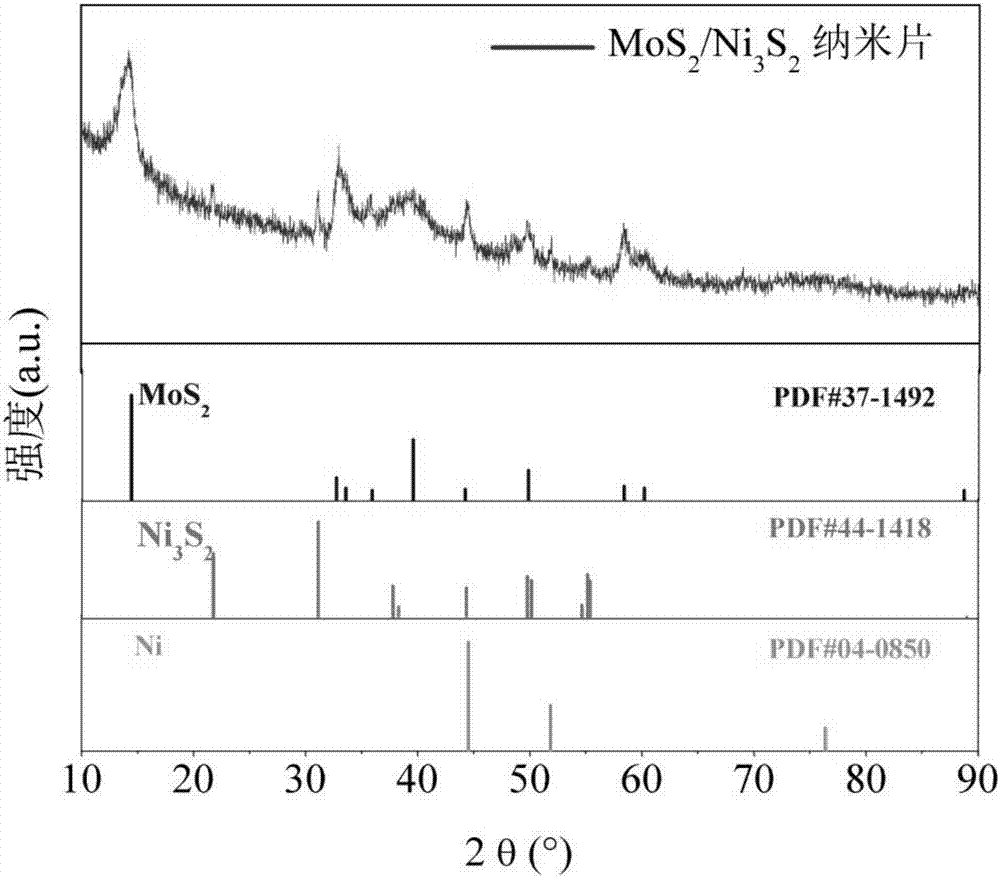

[0032] The structures and properties of the composites prepared by the above method were characterized. figure 1 It is the X-ray diffraction spectrum of the obtained material, and the diffraction peaks in the figure are consistent with PDF#37-1492 and PDF#44-1418, indicating that the material is hexagonal MoS 2 with you 3 S 2 Complex; figure 2 It is the Raman spectrum of the composite material, and MoS can be clearly identified 2 The characteristic absorption peak; image 3 It is a TEM photo of the composite m...

Embodiment 2

[0039] Put 170mg of ammonium molybdate, 60mg of nickel chloride, 3.5g of template and 2g of thioacetamide into a mortar, mix and grind, put the ground powder into a tube furnace, and pass it into argon for protection; then, Raise the burning temperature to 600°C and maintain it for 180 minutes, then raise the burning temperature to 780°C and maintain it for 240 minutes; finally, turn off the heating device, wait for it to cool down to room temperature naturally, and take it out.

[0040] Oxygen reduction reaction catalytic properties: such as Figure 7 As shown, in the alkaline electrolyte (pH 13, 0.1M KOH), under the condition of rotating disc electrode rotating speed of 1600rpm, the onset potential of the oxygen reduction reaction is 975mV, the half-wave potential is 862mV, and the limiting current density is 4.0 mA / cm 2 , compared with commercial 20% Pt / C, the oxygen reduction onset potential and half-wave potential are more positive, indicating that the catalyst has bette...

Embodiment 3

[0042] Put 190mg of ammonium molybdate, 20mg of nickel chloride, 4g of template and 1.5g of thioacetamide into a mortar, mix and grind, put the ground powder into a tube furnace, and pass it into argon protection; then, Raise the burning temperature to 600°C and maintain it for 180 minutes, then raise the burning temperature to 780°C and maintain it for 240 minutes; finally, turn off the heating device, wait for it to cool down to room temperature naturally, and take it out.

[0043] Oxygen reduction reaction catalytic properties: In alkaline electrolyte (pH 13, 0.1M KOH), under the condition of rotating disk electrode speed of 1600rpm, the onset potential of oxygen reduction reaction is 850mV, the half-wave potential is 745mV, and the limiting current The density is 3.2mA / cm 2 , which has a catalytic activity for oxygen reduction reaction close to that of commercial 20% Pt / C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com