Steady-state-method-based device for measuring block heat conductivity coefficient

A technology of thermal conductivity and measuring block, applied in the field of block thermal physical property testing, can solve the problems of unfavorable sample installation and disassembly, cold plate and central hot plate cannot be replaced, single thickness of the sample to be tested, etc., to achieve the effect of flexible testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Embodiment 1 A device for measuring block thermal conductivity based on steady-state method

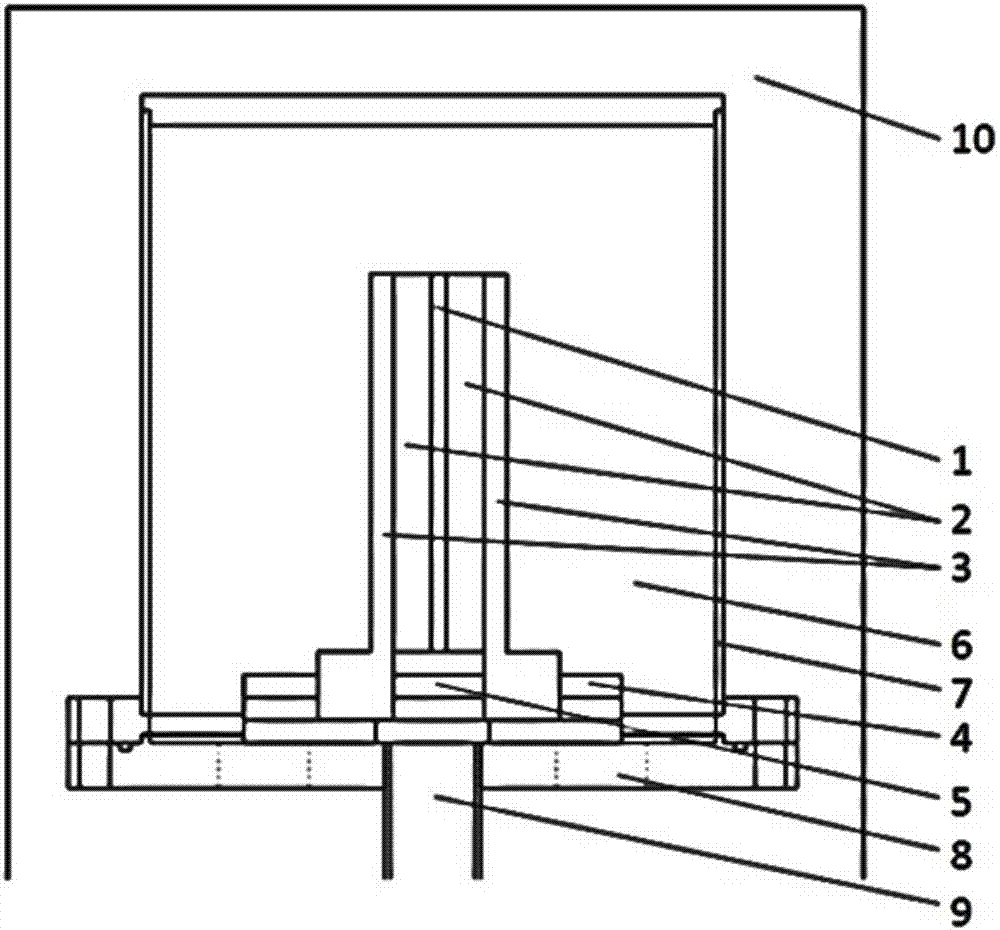

[0052] A device for measuring bulk thermal conductivity based on a steady-state method, the device includes a sample stage 5 for placing a sample to be tested, a vacuum chamber 6 for providing a certain vacuum environment for the sample to be tested, and a vacuum chamber 6 for providing a vacuum for the sample to be tested A constant temperature system 10 providing a certain temperature environment; the sample stage 5 is arranged in the vacuum chamber 6; the vacuum chamber 6 is arranged in the constant temperature system 10;

[0053] The sample stage 5 includes a heat transfer base 4 fixed on the flange, a central hot plate 1 located on the side of the heat transfer base 4 away from the flange, two identical cooling plates symmetrically arranged on both sides of the central hot plate 1 . plate 3, and four thermometers respectively arranged on the heat transfer base 4, the centr...

Embodiment 2

[0063] Example 2 Measure the bulk insulation material at room temperature (25°C), vacuum (10 -3 Thermal conductivity at Pa)

[0064] Use the device shown in Example 1 to measure the temperature of the bulk insulation material at room temperature (25°C) and vacuum (10 -3 Pa) under the thermal conductivity, the method is as follows:

[0065] 1) Installation of the sample stage and the sample to be tested

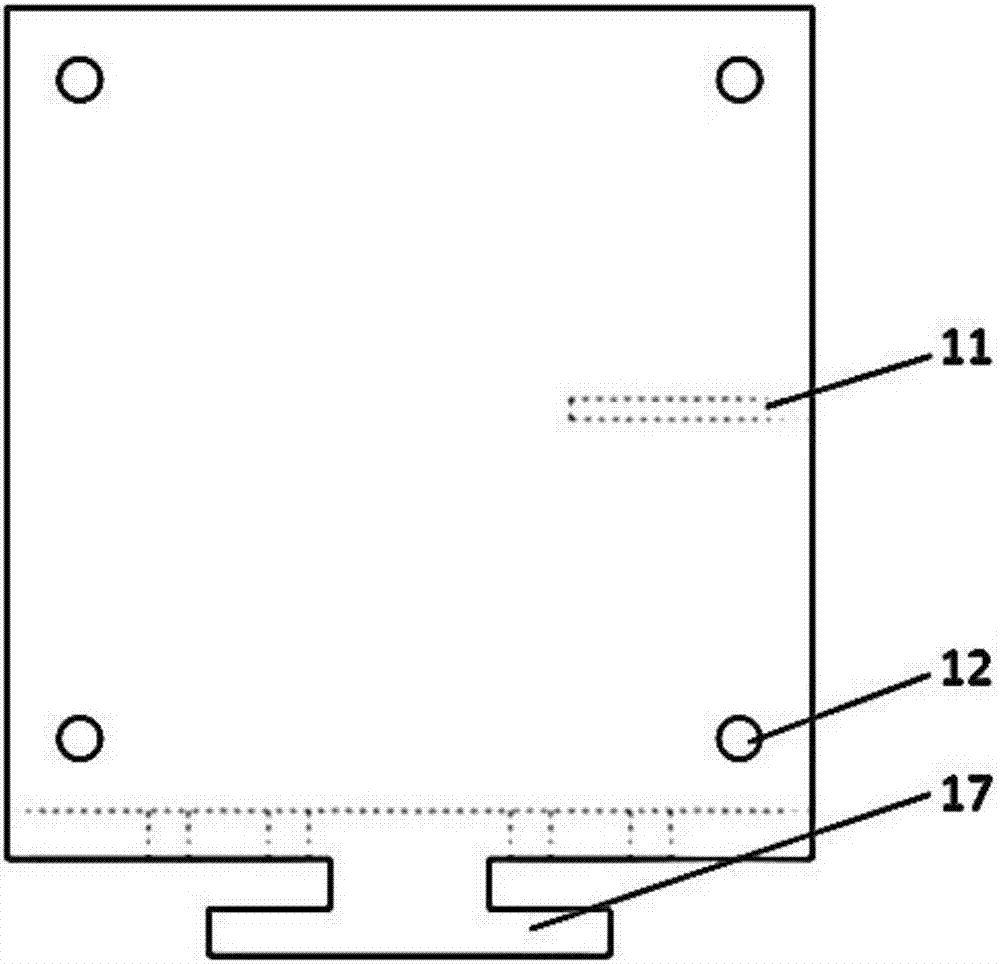

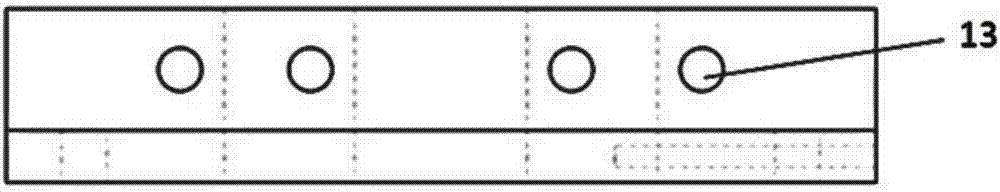

[0066] According to the specifications of the sample to be tested 2 (in the present embodiment, the sample to be tested 2 is a circular plate with a diameter of 100mm and a thickness of 15mm) the appropriate central hot plate 1 is selected (in this embodiment, the central hot plate 1 is Circular plate with a diameter of 100 mm) and cold plate 3 (the cold plate 3 is a square plate with a side length of 100 mm), two identical cold plates 3 are installed with the cold plate on the heat transfer base 4 through the cold plate installation port 17 Slot 16 is coated with silicone ...

Embodiment 3

[0078] Example 3 Measure the bulk insulation material at room temperature (25°C), vacuum (10 -3 Thermal conductivity at Pa)

[0079] Use the device shown in Example 1 to measure the temperature of the bulk insulation material at room temperature (25°C) and vacuum (10 -3 Pa) under the thermal conductivity, the method is as follows:

[0080] 1) Installation of the sample stage and the sample to be tested

[0081] According to the specifications of the sample to be tested 2 (in this embodiment, the sample to be tested 2 is a square plate, the side length is 100mm, and the thickness is 12mm) and the specification selects a suitable central hot plate 1 (in this embodiment, the central hot plate 1 is Square plate, side length is 100mm) and cold plate 3 (cold plate 3 is a square plate, side length is 120mm), two identical cold plates 3 are installed with the cold plate on the heat transfer base 4 through the cold plate installation port 17 Slot 16 is coated with silicone grease an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com