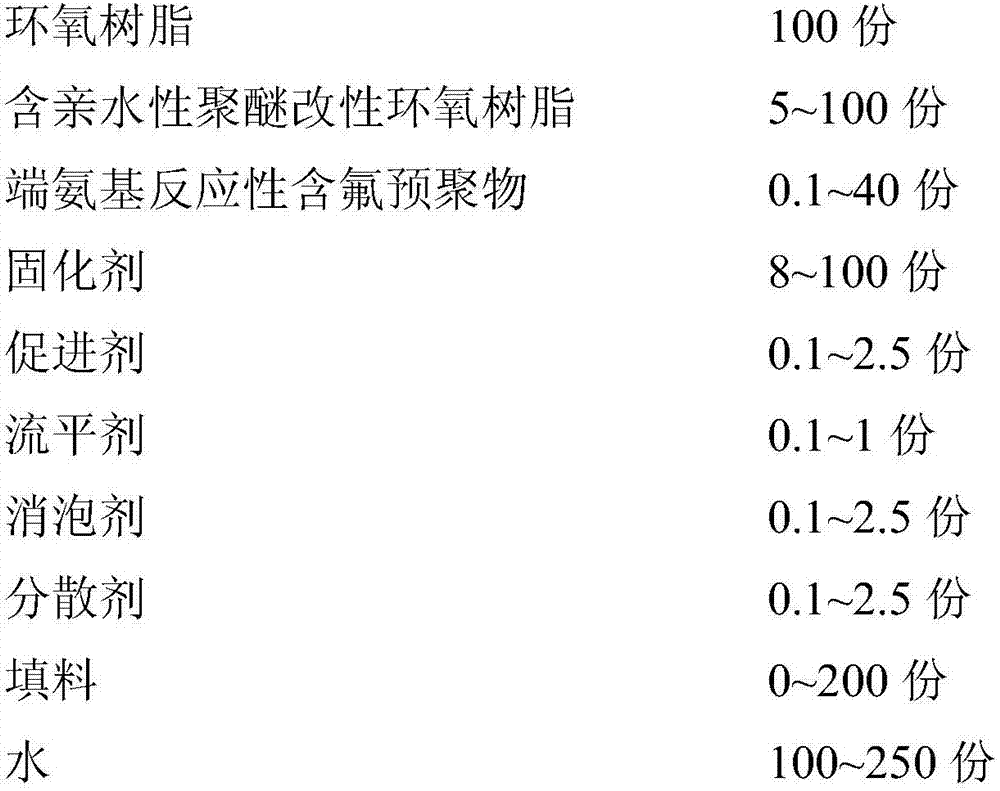

Amine-terminated reactive fluorine-containing polymer modified waterborne epoxy coating, and preparation and application of amine-terminated reactive fluorine-containing polymer modified waterborne epoxy coating

A water-based epoxy coating, reactive technology, applied in the field of polymer coatings, can solve the problems of poor compatibility between organic fluoropolymers and epoxy coatings, increased cost, and difficulty in realizing molecular compounding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

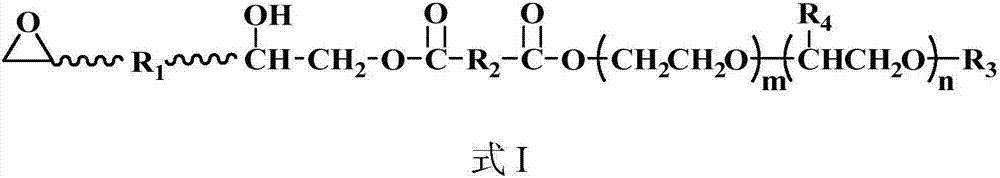

[0059] (1) Preparation of hydrophilic polyether modified epoxy resin: 5 parts by mass of maleic anhydride, 54 parts by mass of polyethylene glycol monomethyl ether ((CH 3 O(CH 2 CH 2 O) n H), relative molecular mass 5000) and 60 mass parts of toluene mix, be warming up to 80 ℃, add 1 mass part of p-toluenesulfonic acid, stir and react for 7 hours, then add 25 mass parts of F-44 type novolac epoxy resin and 2 mass parts Tetrabutylammonium bromide was heated up to 100°C and stirred for 12 hours, and the solvent was distilled off under reduced pressure to obtain a hydrophilic polyether-modified epoxy resin;

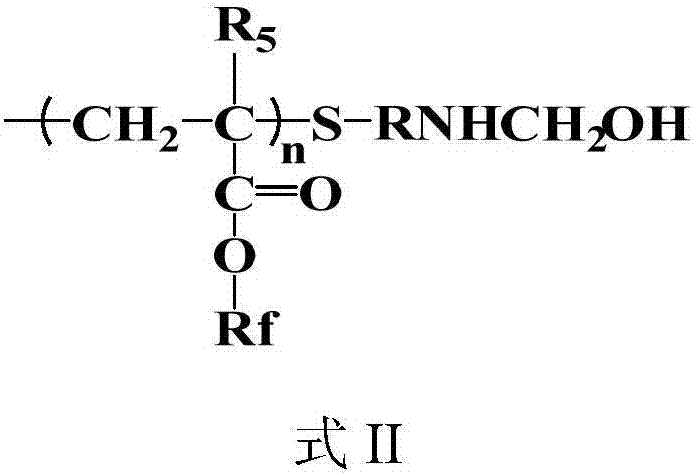

[0060] (2) Preparation of amino-terminated reactive fluorine-containing prepolymer: Add 20 parts by mass of hexafluorobutyl methacrylate and 40 parts by mass of N,N'-dimethylformamide into a container, heat up to 60°C, add 1 part by mass of cysteamine hydrochloride, 0.6 part by mass of azobisisobutyronitrile, stirred and reacted for 8 hours, added triethylamine to make th...

Embodiment 2

[0063] (1) Preparation of hydrophilic polyether-modified epoxy resin: add 10 parts by mass of succinic anhydride and 30 parts by mass of polyoxyethylene monobutyl ether (polyethylene glycol monobutyl ether, relative molecular mass 600) to the container and 40 parts by mass of toluene, heated up to 80°C, added 1 part by mass of triethylamine, stirred and reacted for 7 hours, then added 25 parts by mass of E-51 type epoxy resin and 2 parts by mass of triphenylphosphine, heated to 100°C and stirred Reaction 12h, underpressure distillation removes solvent, obtains containing hydrophilic polyether modified epoxy resin;

[0064] (2) Preparation of amino-terminated reactive fluorine-containing prepolymer: Add 40 parts by mass of hexafluorobutyl methacrylate and 80 parts by mass of N,N'-dimethylformamide into a container, heat up to 60°C, add 4 parts by mass of mercaptoethylamine and 0.8 parts by mass of azobisisobutyronitrile were stirred and reacted for 9 hours, triethylamine was ad...

Embodiment 3

[0067] (1) Preparation of hydrophilic polyether-modified epoxy resin: add 10 parts by mass of phthalic anhydride, 40 parts by mass of polyoxyethylene polyoxypropylene monobutyl ether (relative molecular mass 2000) and 50 parts by mass in a container Parts by mass of toluene, heat up to 80°C, add 1 part by mass of dibutyltin dilaurate, stir and react for 7 hours, then add 25 parts by mass of F-51 type epoxy novolac resin and 2 parts by mass of triethylamine, heat up to 100°C Stirring and reacting for 12h, obtaining a hydrophilic polyether-modified epoxy resin after removing the solvent by distillation under reduced pressure;

[0068](2) Preparation of amino-terminated reactive fluorine-containing prepolymer: Add 30 parts by mass of hexafluorobutyl methacrylate and 60 parts by mass of N,N'-dimethylformamide into a container, heat up to 110°C, add 0.6 parts by mass of mercaptoethylamine and 0.1 parts by mass of azobisisobutyronitrile, stirred and reacted for 9 hours, added diisop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com