A Casting Process for Production of Twin-screw Extruder Barrel Bushings Using High Vanadium-Chromium Ferrochrome

A technology of twin-screw extrusion and high-vanadium ferrochrome, which is applied in the direction of manufacturing tools, casting molding equipment, casting molds, etc., to achieve the effects of improving strength, avoiding cracking, and preventing severe collisions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

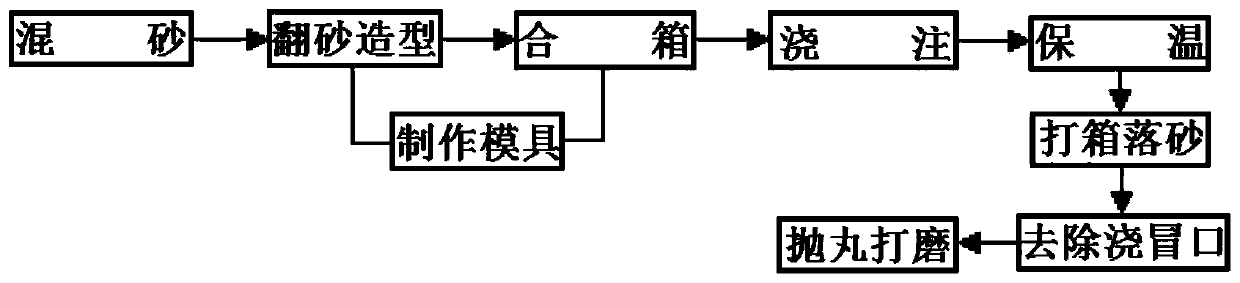

[0059] Such as figure 1 , figure 2 , Figure 5 , Figure 6 and Figure 7 As shown, a casting process for producing twin-screw extruder barrel liners with high vanadium ferrochrome in this embodiment includes the following process steps:

[0060] Step 1: Sand mixing, the performance of the sand is controlled at 4.5-5.5% moisture, air permeability 110-140, wet compressive strength 120-150kPa, compaction rate 38-42%;

[0061] Step 2: Make a mold, including foundry molding and box closing, forming an upper box with two ingates 6 and a heating riser 7 and a lower box with graphite cold iron 8, and the upper box and the lower box. Form a molding chamber 11 for producing the cylinder liner of a twin-screw extruder, and the upper box and the lower box are provided with a side-mounted pouring channel;

[0062] Step 3: pouring, including pouring with high-vanadium-chromium iron molten iron, the molten iron enters the molding cavity 11 of the cylinder liner of the twin-screw extrud...

Embodiment 2

[0069] Such as figure 1 , figure 2 , Figure 5 and Figure 6 As shown, a casting process of producing twin-screw extruder cylinder liners with high vanadium chromium ferrochrome in this embodiment, the specific process of said step 2:

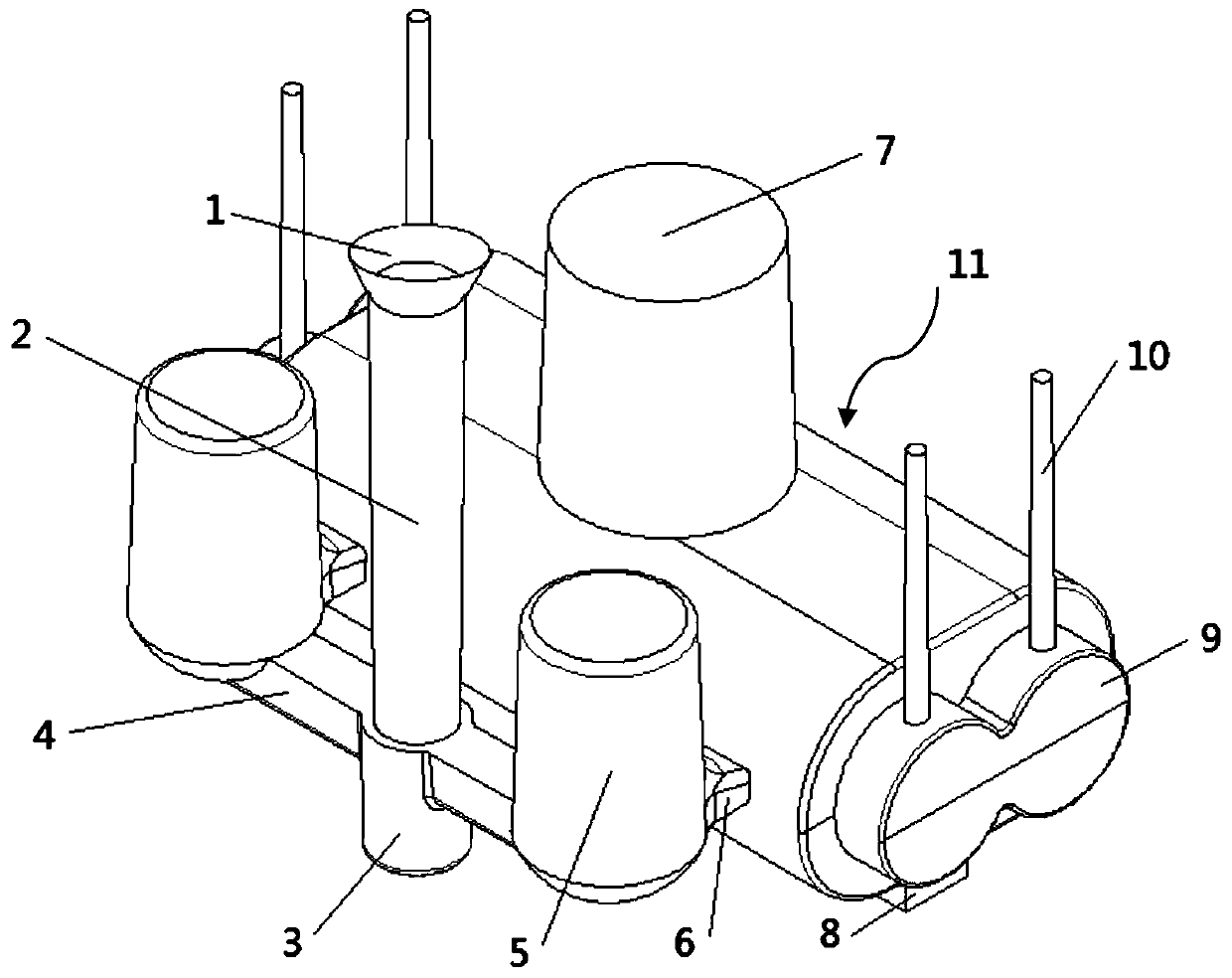

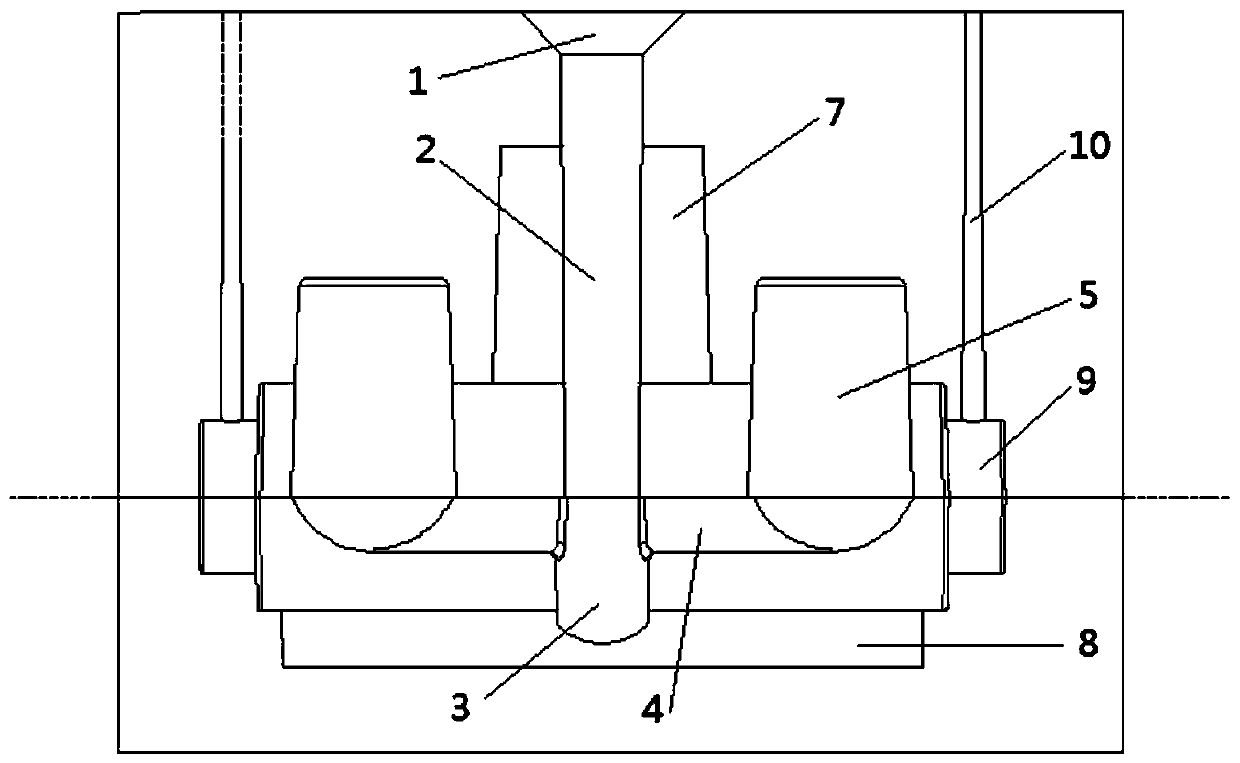

[0070] (1) Foundry molding, molding a side-mounted pouring channel connected with the outer gate 1 in the upper box body and the lower box body, the side-mounted pouring channel includes sprue 2, sprue nest 3, and runner 4. Ordinary measuring riser 5 and ingate 6, the bottom of the sprue 2 is provided with a sprue nest 3; the upper part of the sprue nest 3 is connected with the horizontal runner 4; The ends of the runners 4 are respectively connected with common side risers 5; the two common side risers 5 are respectively connected with two ingates 6; the two ingates 6 communicate with the molding cavity 11;

[0071] (2) Close the box to form a complete box to be poured.

[0072] In this embodiment, when pouring, the high-vanadium-chromiu...

Embodiment 3

[0074] Such as figure 1 , figure 2 , Figure 5 and Figure 6 As shown, a casting process of producing a twin-screw extruder cylinder liner with high vanadium chromium ferrochrome in this embodiment, the specific steps of the foundry molding are as follows:

[0075] a. Spray release agent into the upper box molding machine, reserve the position of heating riser 7, then add green sand, and press it to make a funnel-shaped outer gate 1, which communicates with the side-mounted pouring channel ;

[0076] b Turn over the box, then add the heating riser 7 to make the upper box;

[0077] c. Spray release agent into the lower box molding machine, put in graphite cold iron 8, then add green sand, turn over the box after compaction, and make the lower box;

[0078] The mud core 9 that d puts in the lower casing is a film-coated sand mud core;

[0079] e Cover the filter screen on the sprue nest 3, the runner 4 and the common side riser 5 of the lower box body.

[0080] In this e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com