Modular converter

A converter and modular technology, applied in the direction of converting AC power input to DC power output, electric solid-state devices, semiconductor devices, etc., can solve inconvenient assembly, disassembly and maintenance, unreasonable component layout, and converter module Bulkiness and other problems, to achieve the effect of improving space utilization, compact structure, and improving component layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

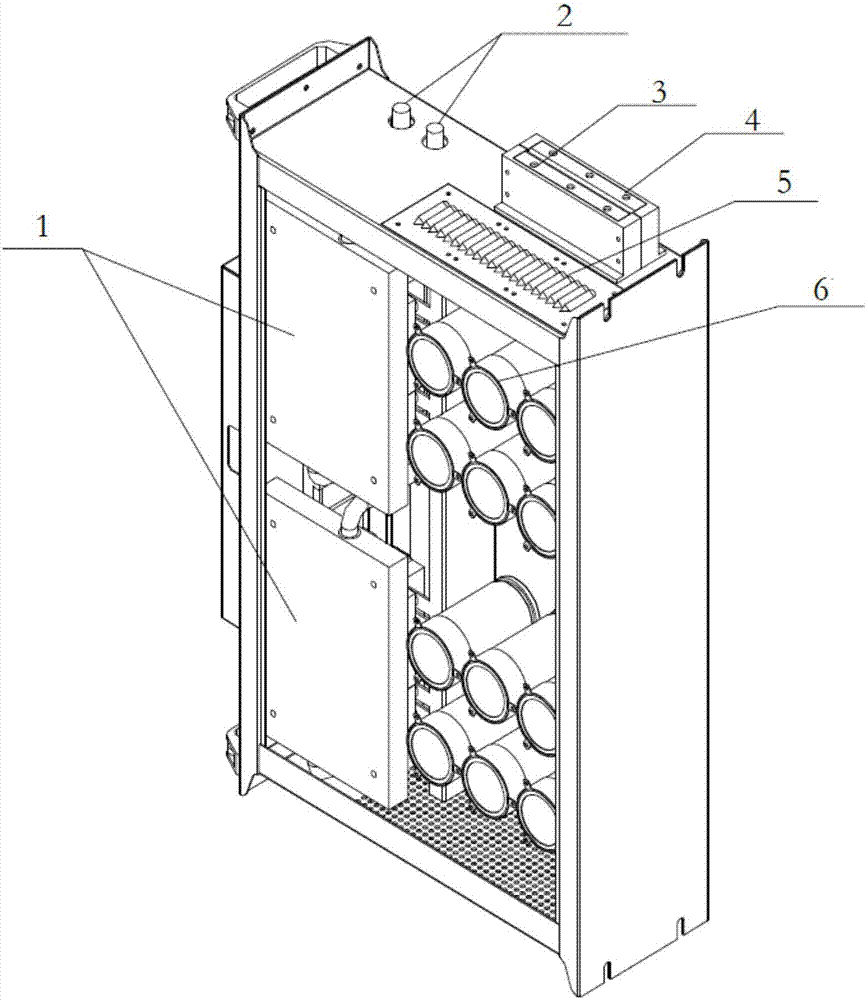

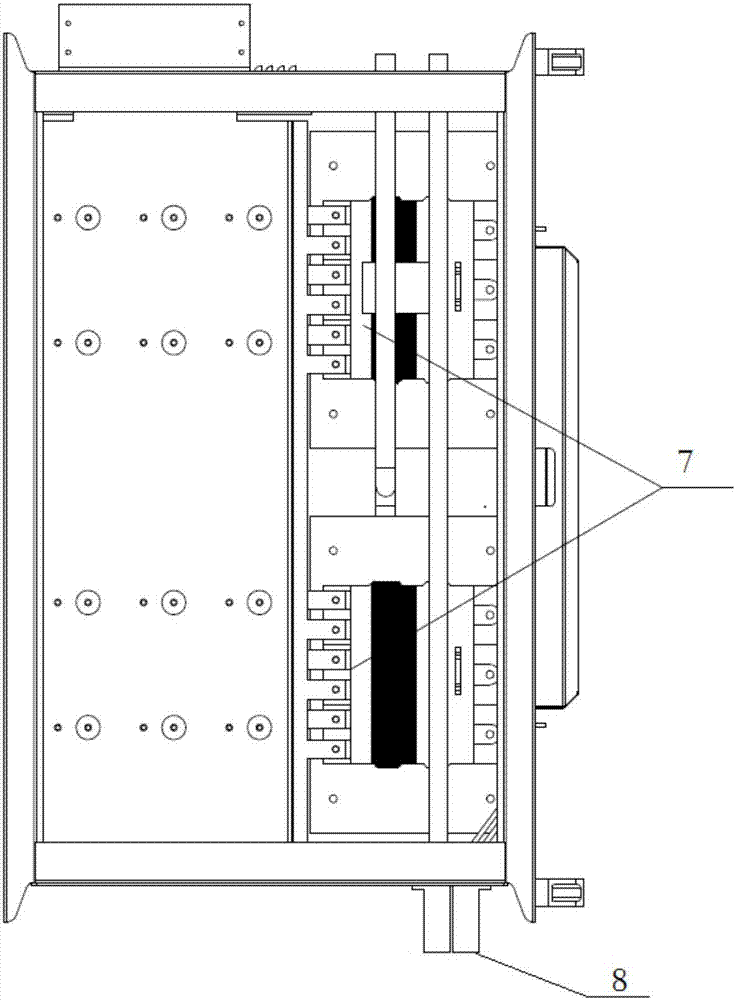

[0031] like figure 1 , figure 2 As shown, a modular converter is a vertical frame structure, including:

[0032] 2 IGBT modules 7, arranged longitudinally in the vertical frame; 2 radiators 1, respectively arranged on the surface of one side of the 2 IGBT modules 7; DC busbar assembly, placed vertically, including stacked positive DC busses The row 4 and the negative DC busbar 3 are arranged in the vertical frame side by side with the IGBT module 7; a plurality of absorption capacitors 6 are connected in parallel with the DC terminals of the IGBT module, and are evenly arranged on the surface of the DC busbar assembly; the AC busbar 8. The IGBT module 7 is connected to the surface of the IGBT module 7 on the side where the heat sink 1 is not provided.

[0033] Due to the large volume and large number of absorption capacitors 6, it is not easy to directly connect with the IGBT module pins. The design of the laminated busbar can solve this problem very well. The positive DC b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com