Metal cavity-based surface plasmon laser

A technology of surface plasmons and lasers, applied in lasers, laser components, semiconductor lasers, etc., can solve the problems of large reflection loss, difficult to control the physical size and shape of nanowires precisely, and achieve low loss and strong binding ability , The effect of reducing reflection loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

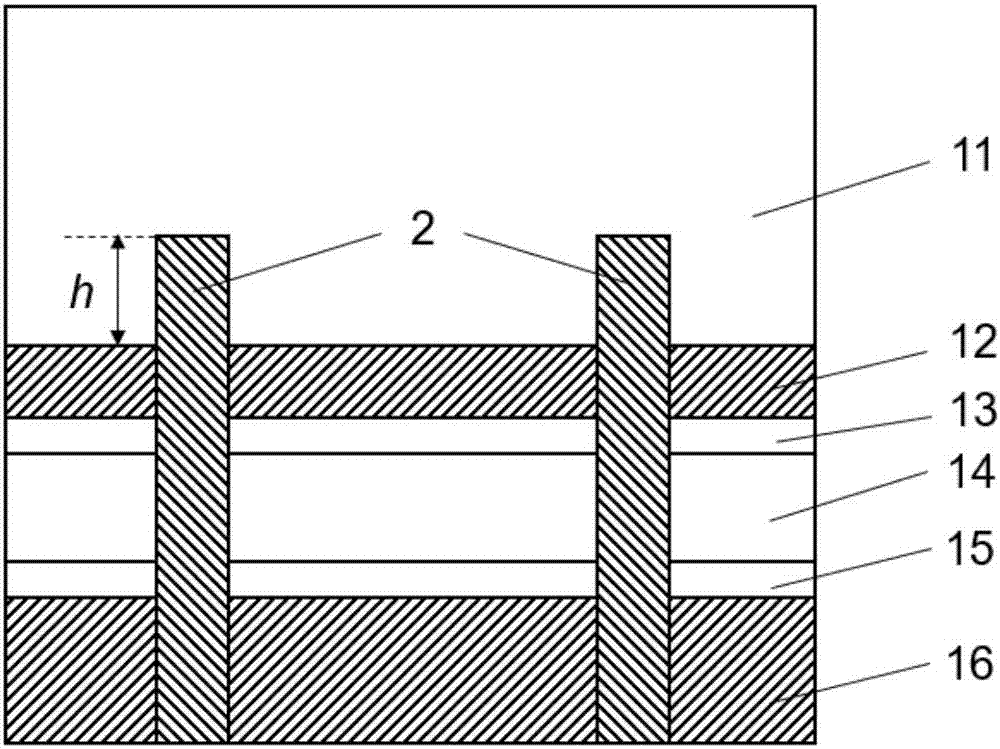

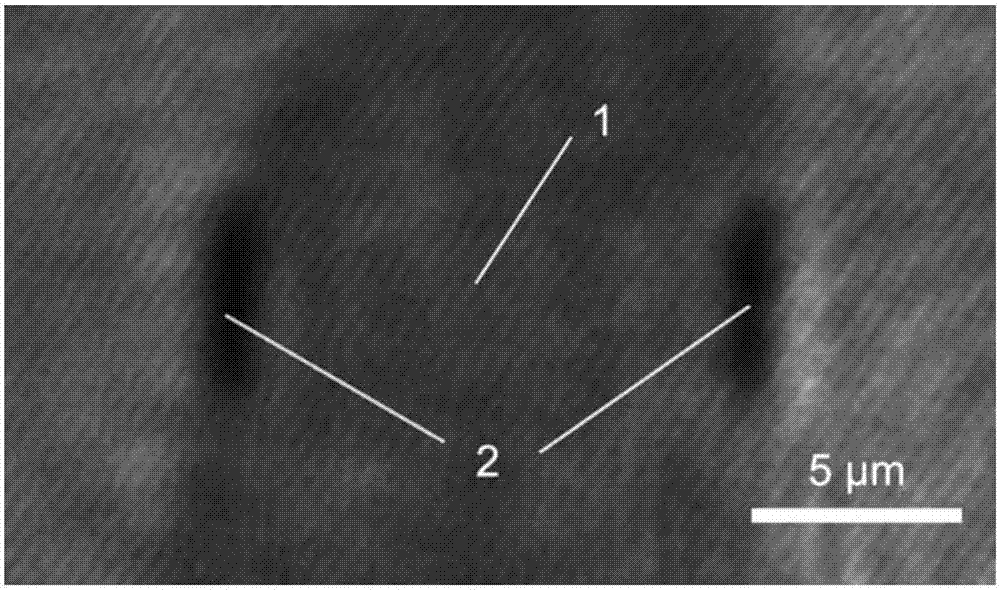

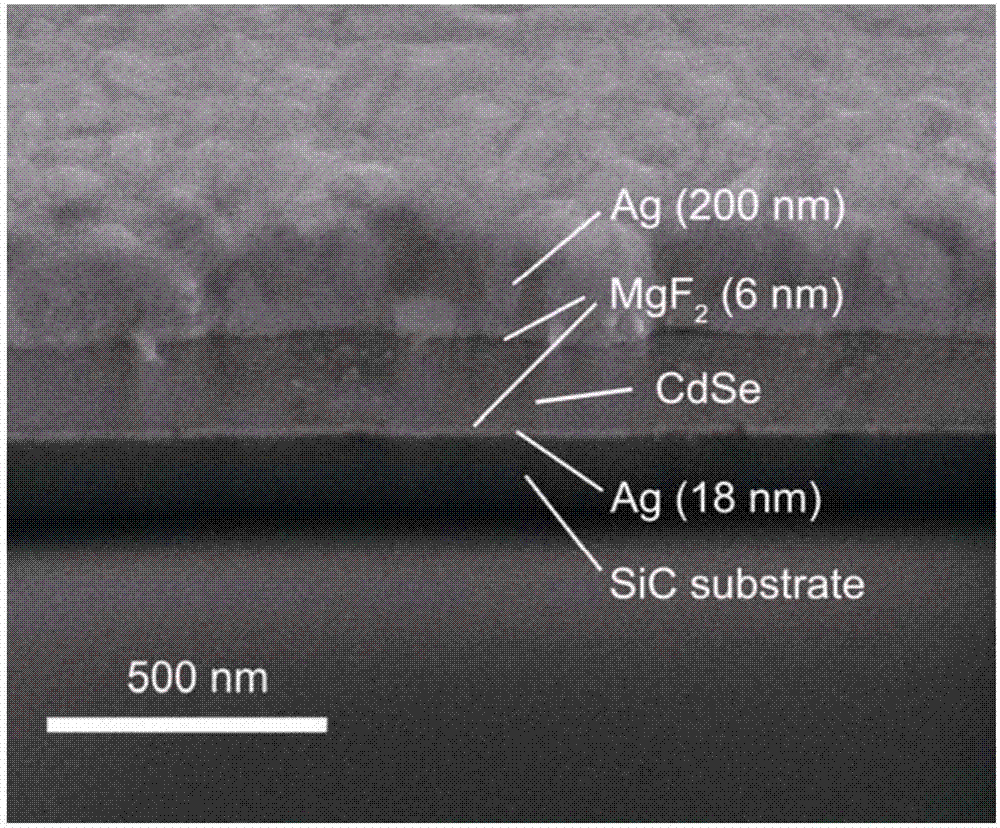

[0025] Such as figure 1 and figure 2 As shown, the metal cavity-based surface plasmon laser of this embodiment includes: a surface plasmon waveguide 1 and a metal cavity 2; wherein the surface plasmon waveguide 1 further includes a high refractive index transparent substrate layer 11, Metal thin film layer 12, insulating medium layer 13, gain medium layer 14, insulating medium layer 15 and metal thick film layer 16; Metal thin film layer 12 is plated on the transparent substrate layer 11, insulating medium layer 13 is plated on the metal thin film layer 12, The gain medium layer 14 is a semiconductor nanobelt, which is closely attached to the surface of the insulating medium layer 13 without gaps. The insulating medium layer 15 is plated on the gain medium layer 14 , and the metal thick film layer 16 is plated on the insulating medium layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com