Partition plate cone body forming method for soft partition plate for double-pulse engine

A molding method and engine technology, applied in machine/engine, rocket engine device, application, etc., can solve problems such as engine explosion and can not fly out as a whole, and achieve the effect of ensuring airtight performance and ensuring overall shedding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

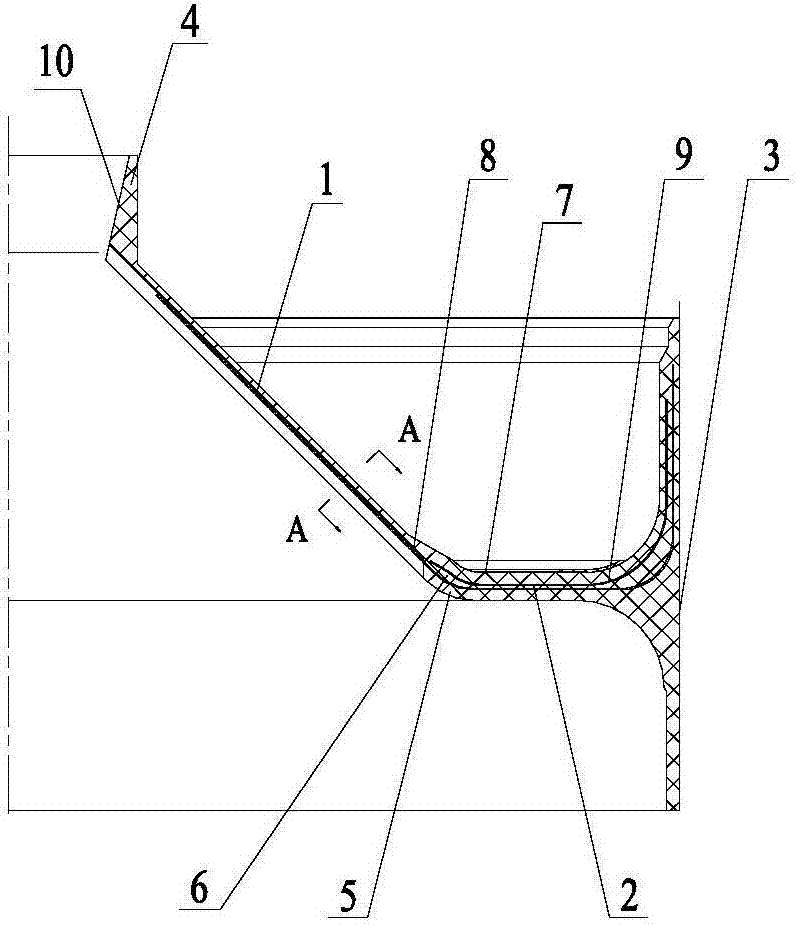

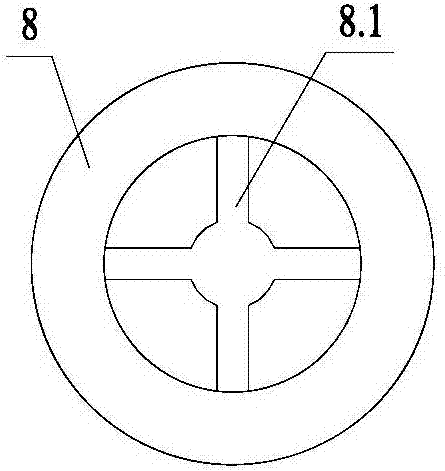

[0049] A method for forming a partition cone of a soft partition for a double-pulse engine, comprising the following steps:

[0050] 1) When the die is heated to 380-420°C, degrease the surface of the die at high temperature; then the surface of the die is sanded and roughened, and after cleaning, the surface of the die is sprayed with polytetrafluoroethylene. The primary coating is sintered at 420°C; after the primary coating is sintered, spray polytetrafluoroethylene on the surface of the die, and the secondary coating is sintered at 380-420°C, and the secondary coating is sintered for use;

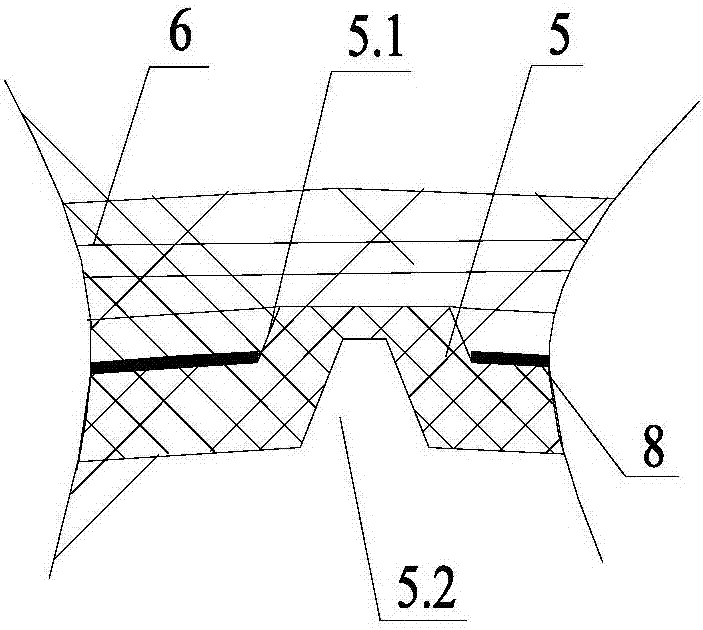

[0051] 2) Put the inner layer of EPDM into the compression mold after step 1) pretreatment for pre-vulcanization, forming the inner layer of EPDM 5, the contour of the inner layer of EPDM 5 is separated from the product The outline of the plate cone is consistent; the pre-vulcanization temperature is 120°C, and the pre-vulcanization time is 35min. The advantages of preforming the botto...

Embodiment 2

[0057] A method for forming a partition cone of a soft partition for a double-pulse engine, comprising the following steps:

[0058] 1) When the die is heated to 380-420°C, degrease the surface of the die at high temperature; then the surface of the die is sanded and roughened, and after cleaning, the surface of the die is sprayed with polytetrafluoroethylene. The primary coating is sintered at 420°C; after the primary coating is sintered, spray polytetrafluoroethylene on the surface of the die, and the secondary coating is sintered at 380-420°C, and the secondary coating is sintered for use;

[0059] 2) Put the inner layer of EPDM into the compression mold after step 1) pretreatment for pre-vulcanization, forming the inner layer of EPDM 5, the contour of the inner layer of EPDM 5 is separated from the product The outline of the plate cone is consistent; the pre-curing temperature is 120 ° C, and the pre-curing time is 30 minutes. The advantages of preforming the bottom layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com