Door handle grinding and polishing clamp with anti-winding function for robot

A technology of polishing jigs and robots, which is applied in grinding/polishing equipment, grinding machines, manipulators, etc., can solve the problems of not being able to meet the needs of manufacturers and users, not being able to polish and cover, and not being convenient to use, etc., so as to be convenient for daily use and Maintenance, improved grinding efficiency and precision, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

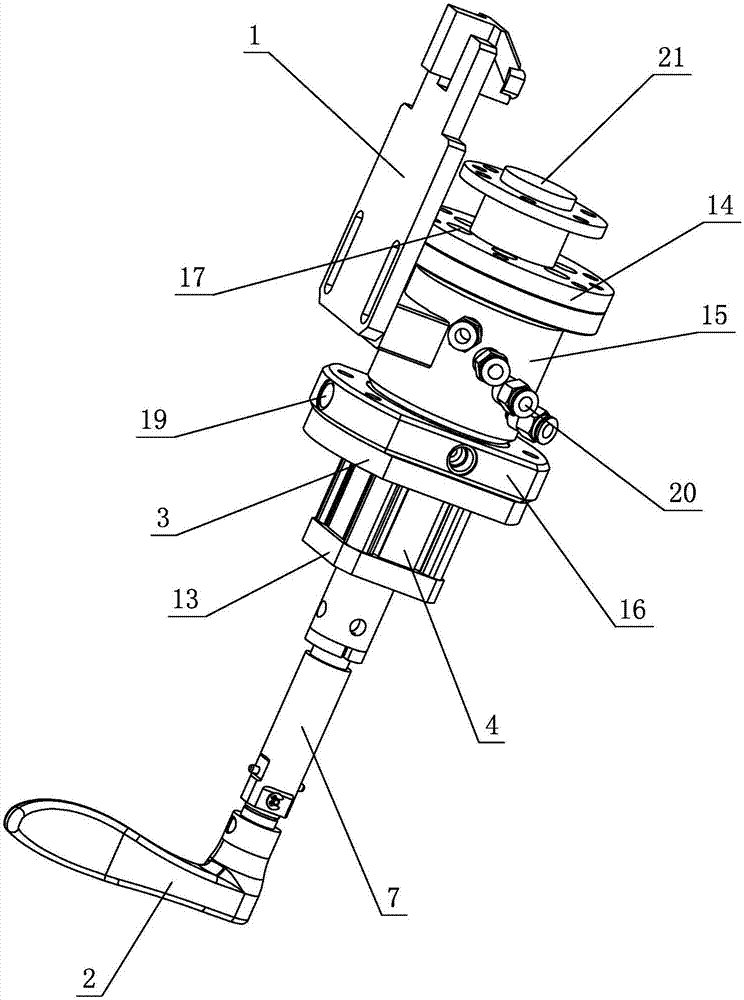

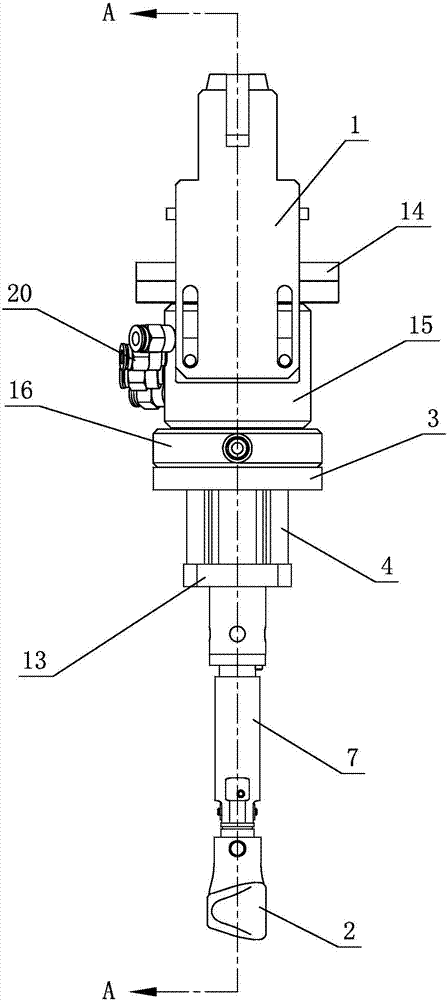

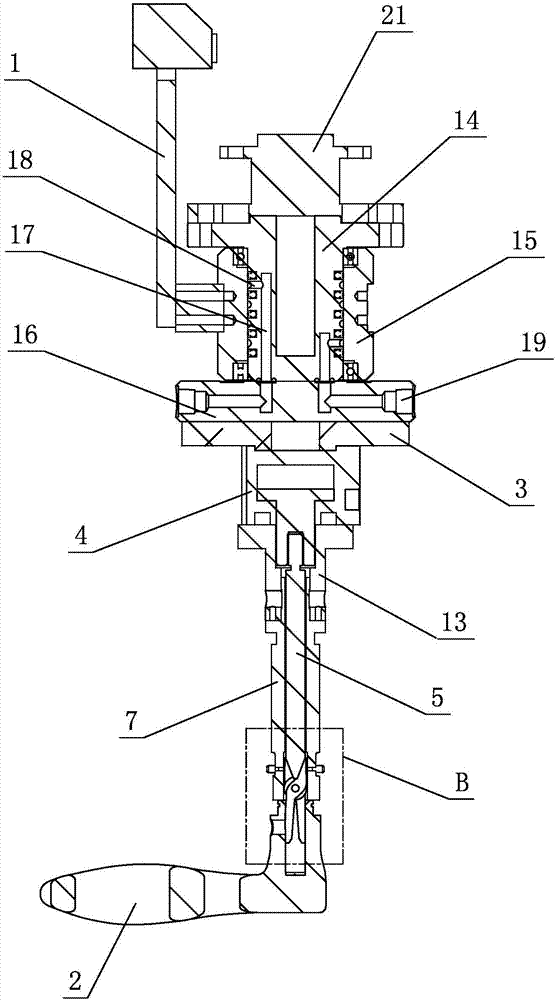

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0020] see Figure 1-Figure 4 , the door handle robot grinding and polishing jig with anti-winding, including the fifth axis fixing mechanism 1 of the robot, the infinite rotation mechanism, the door handle fixture and the door handle workpiece 2, wherein the infinite rotation mechanism is connected with the fifth axis fixing mechanism 1 of the robot , the door handle fixture is connected with the infinite rotation mechanism, and the door handle fixture at least includes a robot connection flange 3, a tension cylinder 4, a tension thimble 5, and a tension clip 6; wherein, the robot connection flange 3 cooperates with the infinite rotation mechanism connection, the tensioning cylinder 4 is arranged on the robot connecting flange 3, and is drivingly connected with the tensioning thimble 5, and the tensioning thimble 5 drives the tensioning clip 6 through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com