Antique brass paint spraying process

A process and workpiece technology, applied in the field of antique copper painting technology, can solve the problems of sign surface paint wrinkling, reduce the service life of signs, peeling, etc., achieve smooth and smooth surface, improve UV resistance and weather resistance, and improve wear resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

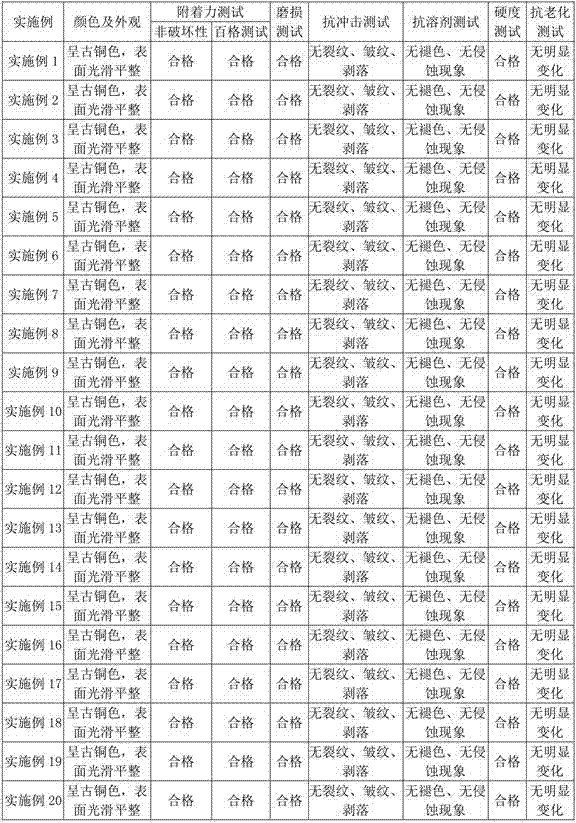

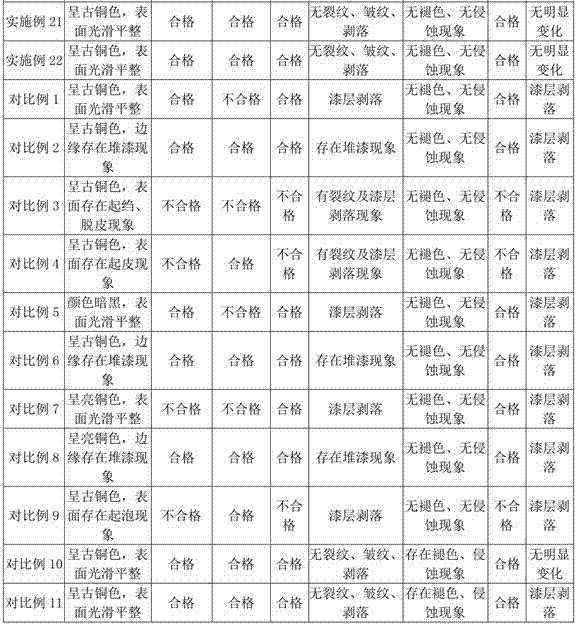

Examples

Embodiment 1

[0043] Embodiment 1: a kind of antique copper painting technique comprises the following steps:

[0044] Step 1, pretreatment of workpiece surface;

[0045] (1) Select a metal workpiece suitable for processing. The surface of the workpiece to be processed should not have irreparable deformation such as concave light. The weld seam has no welding slag and other debris that is easy to fall off. Defects such as deformation and cracking that affect the adhesion of the paint layer;

[0046] (2) Check whether the surface of the workpiece is clean, and use isoamyl acetate solution to scrub the stains and oil stains on the surface of the workpiece;

[0047] (3) Scrape the surface of the workpiece with uneven surface or the surface of the workpiece with cracks. After scraping, place the workpiece at 30°C and a relative humidity of 65% for two hours to dry the atomic ash, and then use 80# Dry sand the workpiece with sandpaper, or put 80# sandpaper on the steam-powered grinder to grind...

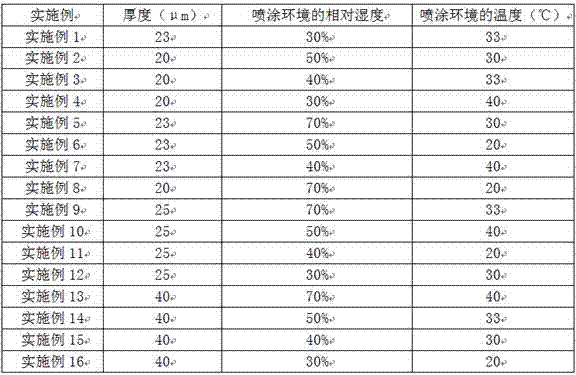

Embodiment 17

[0062] An antique copper painting process, the difference between embodiment 17 and embodiment 1 is that the thickness of the copper-color finish paint layer is 35 μm.

Embodiment 18

[0064] An antique copper painting process, the difference between embodiment 18 and embodiment 1 is that the thickness of the copper-colored finish paint layer is 40 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com