Composite acid solid catalyst PVP-HNTs@UiO-66-SO3H and preparation method thereof

An acidic solid, catalyst technology, used in catalyst activation/preparation, organic compound/hydride/coordination complex catalysts, chemical instruments and methods, etc. Insufficient performance and other problems, to achieve the effect of low cost, simple preparation process and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

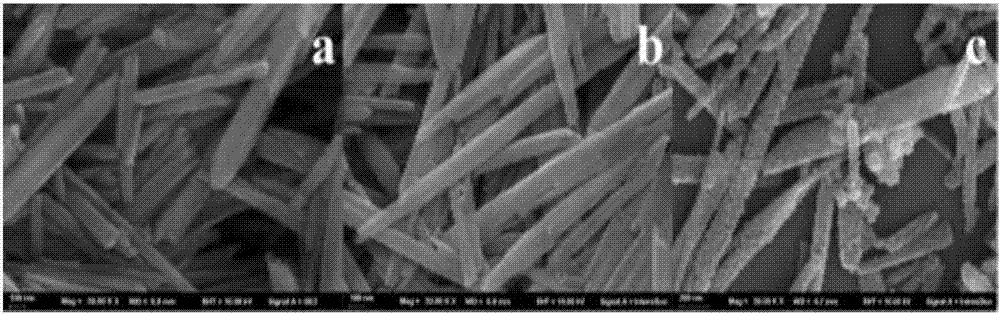

[0030] 1. PVP-HNTs@UiO-66-SO 3 The preparation method of H is characterized in that it is carried out according to the following steps:

[0031] (1) 0.1g HNTs was dispersed in 1g / mL 50mL PVP aqueous solution, and then ultrasonically dispersed to form a mixed system. The reaction system was reacted at 30° C. for 12 h under magnetic stirring. After the reaction, the obtained product was washed with deionized water, collected by centrifugation, and dried in vacuum to obtain modified PVP-HNTs.

[0032] (2) 0.025g of PVP-HNTs, 0.04g of zirconium chloride and 0.04g of 2-sulfonic acid terephthalic acid were dissolved in 20mL of N,N-dimethylformamide and weak acid mixed solution, which contained 16mL of N , N-dimethylformamide and 4mL of weak acid, and ultrasonically disperse the resulting mixture evenly. Then the dispersed mixed solution was placed in a reactor at 100° C. for 12 h. After the reaction, the obtained product was centrifuged, washed, soaked in methanol for 2 days, an...

Embodiment 2

[0050] 1. PVP-HNTs@UiO-66-SO 3 The preparation method of H is characterized in that it is carried out according to the following steps:

[0051] (1) 1g HNTs was dispersed in 2.5g / mL 250mL PVP aqueous solution, and then ultrasonically dispersed to form a mixed system. The reaction system was reacted at 60° C. for 18 h under magnetic stirring. After the reaction, the obtained product was washed with deionized water, collected by centrifugation, and dried in vacuum to obtain modified PVP-HNTs.

[0052] (2) 2.5g of PVP-HNTs, 1.4g of zirconium chloride and 1.4g of 2-sulfonic acid terephthalic acid were dissolved in 150mL of N,N-dimethylformamide and weak acid mixed solution, which contained 90mL of N , N-dimethylformamide and 60mL of weak acid, and ultrasonically disperse the resulting mixture evenly. Then the dispersed mixed solution was placed in a reaction kettle at 150° C. for 24 h. After the reaction, the obtained product was centrifuged, washed, soaked in methanol for 2 d...

Embodiment 3

[0060] 1. PVP-HNTs@UiO-66-SO 3 The preparation method of H is characterized in that it is carried out according to the following steps:

[0061] (1) 10g HNTs were dispersed in 5g / mL 500mL PVP aqueous solution, and then ultrasonically dispersed to form a mixed system. The reaction system was reacted at 90° C. for 24 h under magnetic stirring. After the reaction, the obtained product was washed with deionized water, collected by centrifugation, and dried in vacuum to obtain modified PVP-HNTs.

[0062] (2) 5g of PVP-HNTs, 2.4g of zirconium chloride and 2.7g of 2-sulfonic acid terephthalic acid were dissolved in 250mL of N,N-dimethylformamide and weak acid mixed solution, which contained 220mL of N, N-dimethylformamide and 30mL of weak acid, and the resulting mixture was dispersed uniformly by ultrasonic. Then the dispersed mixed solution was placed in a reactor at 180° C. for 36 h. After the reaction, the obtained product was centrifuged, washed, soaked in methanol for 2 days...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com