A kind of processing method of rain dew hemp spinning and weaving

A processing method, rain dew hemp technology, applied in textiles, textiles, papermaking, yarn, etc., can solve the problems of low yield and adverse effects, and achieve high work efficiency, thin laying thickness, and non-irritating effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

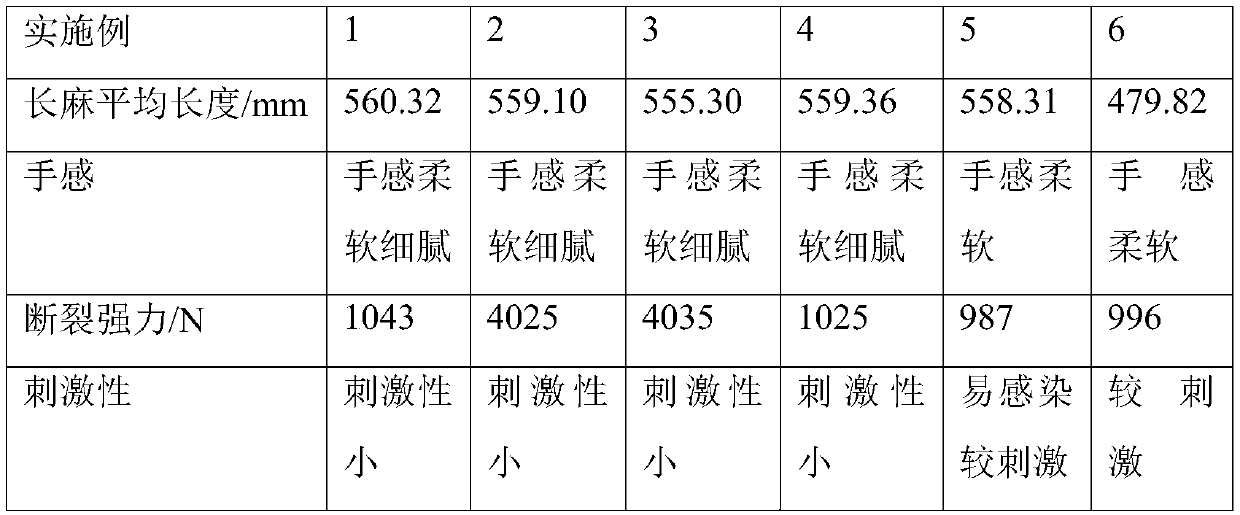

Examples

Embodiment 1

[0044] A processing method for rain dew hemp spinning and weaving, comprising the steps of:

[0045] S1 Rain retting flax: lay the hemp stalks on the wheat or flax field, retting until the hemp stalks turn to silver gray, and get the flax for use;

[0046] S2 flax pretreatment: After the flax in step S1 is oiled by the flax softening machine, it is stacked for health preservation, and then cut and flax is processed to obtain dry flax for use;

[0047] S3 spinning: blending dry hemp and blended ingredients in step S2 to obtain blended raw materials, and performing carding, drawing, roving, spun yarn and winding processes on the blended raw materials to obtain dry hemp cheese yarns for use;

[0048] S4 weaving: the dry hemp cheese in the step S3 is processed into a dry hemp fabric through the processes of warping, soaking, sizing, reeding, weft winding, weaving and cloth inspection.

[0049] Specifically, in the S1 step, the hemp stems are laid with a thickness of 1-2 cm, and t...

Embodiment 2

[0067] A processing method for rain dew hemp spinning and weaving, comprising the steps of:

[0068] S1 Rain retting flax: lay the hemp stalks on the wheat or flax field, retting until the hemp stalks turn to silver gray, and get the flax for use;

[0069] S2 flax pretreatment: After the flax in step S1 is oiled by the flax softening machine, it is stacked for health preservation, and then cut and flax is processed to obtain dry flax for use;

[0070] S3 spinning: blending dry hemp and blended ingredients in step S2 to obtain blended raw materials, and performing carding, drawing, roving, spun yarn and winding processes on the blended raw materials to obtain dry hemp cheese yarns for use;

[0071] S4 weaving: the dry hemp cheese in the step S3 is processed into a dry hemp fabric through the processes of warping, soaking, sizing, reeding, weft winding, weaving and cloth inspection.

[0072] Specifically, in the S1 step, the hemp stems are laid with a thickness of 1-2 cm, and t...

Embodiment 3

[0090] A processing method for rain dew hemp spinning and weaving, comprising the steps of:

[0091] S1 Rain retting flax: lay the hemp stalks on the wheat or flax field, retting until the hemp stalks turn to silver gray, and get the flax for use;

[0092] S2 flax pretreatment: After the flax in step S1 is oiled by the flax softening machine, it is stacked for health preservation, and then cut and flax is processed to obtain dry flax for use;

[0093] S3 spinning: blending dry hemp and blended ingredients in step S2 to obtain blended raw materials, and performing carding, drawing, roving, spun yarn and winding processes on the blended raw materials to obtain dry hemp cheese yarns for use;

[0094] S4 weaving: the dry hemp cheese in the step S3 is processed into a dry hemp fabric through the processes of warping, soaking, sizing, reeding, weft winding, weaving and cloth inspection.

[0095] Specifically, in the S1 step, the hemp stems are laid with a thickness of 1-2 cm, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com