Aluminum alloy surface treatment method of microarc oxidation combined with pulse electrodeposition hole sealing and pulse electrodeposition hole sealing device

A technology of pulse electrodeposition, aluminum alloy surface, applied in surface reaction electrolytic coating, anodizing, electrolytic coating, etc., can solve the problems of unfriendly environment, reduced application, colored film, etc., to achieve environmental friendliness and good protection Excellent effect on function and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

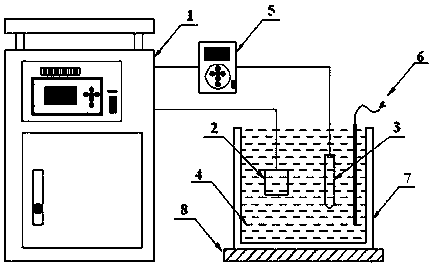

Image

Examples

Embodiment 1

[0047] A method for surface treatment of an aluminum alloy with micro-arc oxidation combined with pulse electrodeposition sealing, comprising the following steps:

[0048] (i) Pretreatment

[0049] (a) Degreasing treatment

[0050] Wash the surface of the sample with NaOH solution for 10 minutes to remove the oil on the surface of the sample;

[0051] (b) Grinding treatment

[0052] Grind the degreased sample with 240﹟, 400﹟, 600﹟, 800﹟, 1000﹟ sandpaper step by step until it is clean and bright without obvious scratches;

[0053] (c) Ultrasonic cleaning

[0054] Put the polished sample into absolute ethanol and ultrasonically clean it for 15 minutes, wash it with deionized water and dry it for later use;

[0055] (ii) Micro-arc oxidation treatment

[0056] Put the sample after pretreatment in the electrolyte of silicate system, use the sample as the anode, and make the sample completely submerged below the liquid level of the electrolyte, and the stainless steel electrolyti...

Embodiment 2

[0072] A method for surface treatment of an aluminum alloy with micro-arc oxidation combined with pulse electrodeposition sealing, comprising the following steps:

[0073] (i) Pretreatment

[0074] (a) Degreasing treatment

[0075] Wash the surface of the sample with NaOH solution for 10 minutes to remove the oil on the surface of the sample;

[0076] (b) Grinding treatment

[0077] Grind the degreased sample with 240﹟, 400﹟, 600﹟, 800﹟, 1000﹟ sandpaper step by step until it is clean and bright without obvious scratches;

[0078] (c) Ultrasonic cleaning

[0079] Put the polished sample into absolute ethanol and ultrasonically clean it for 15 minutes, wash it with deionized water and dry it for later use;

[0080] (ii) Micro-arc oxidation treatment

[0081] Put the sample after pretreatment in the electrolyte of silicate system, use the sample as the anode, and make the sample completely submerged below the liquid level of the electrolyte, and the stainless steel electroly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com