A kind of epoxy leather tanning agent and preparation method thereof

A technology for tanning agent and leather, applied in the field of tanning agent for leather tanning and its preparation, can solve the problems of high cost, intolerant storage of water-based epoxy compounds, long tanning time, etc., and achieves high humidity and heat resistance stability, excellent yellowing resistance The effect of changing properties and reducing product viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

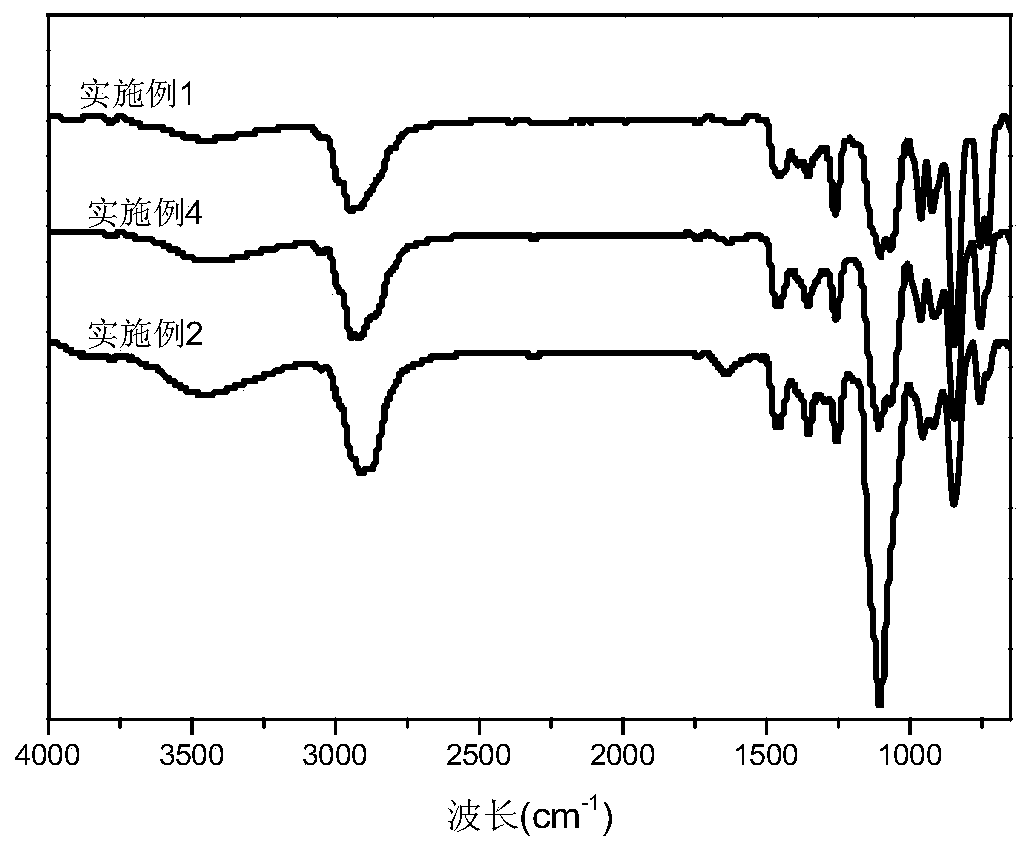

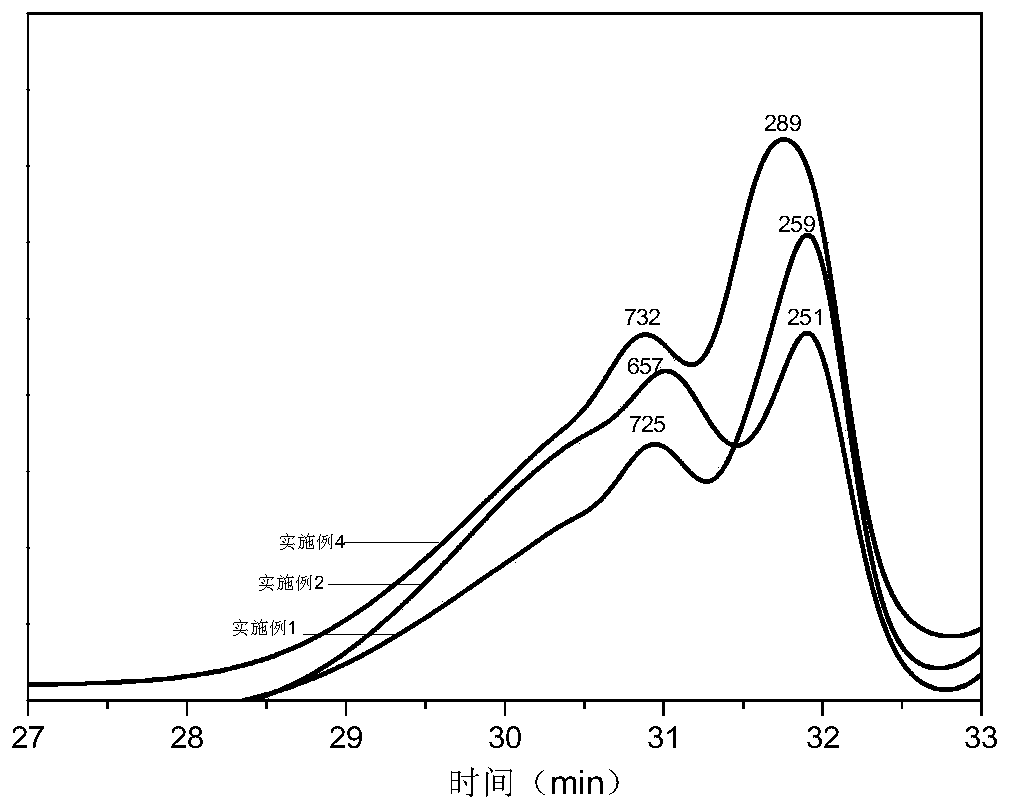

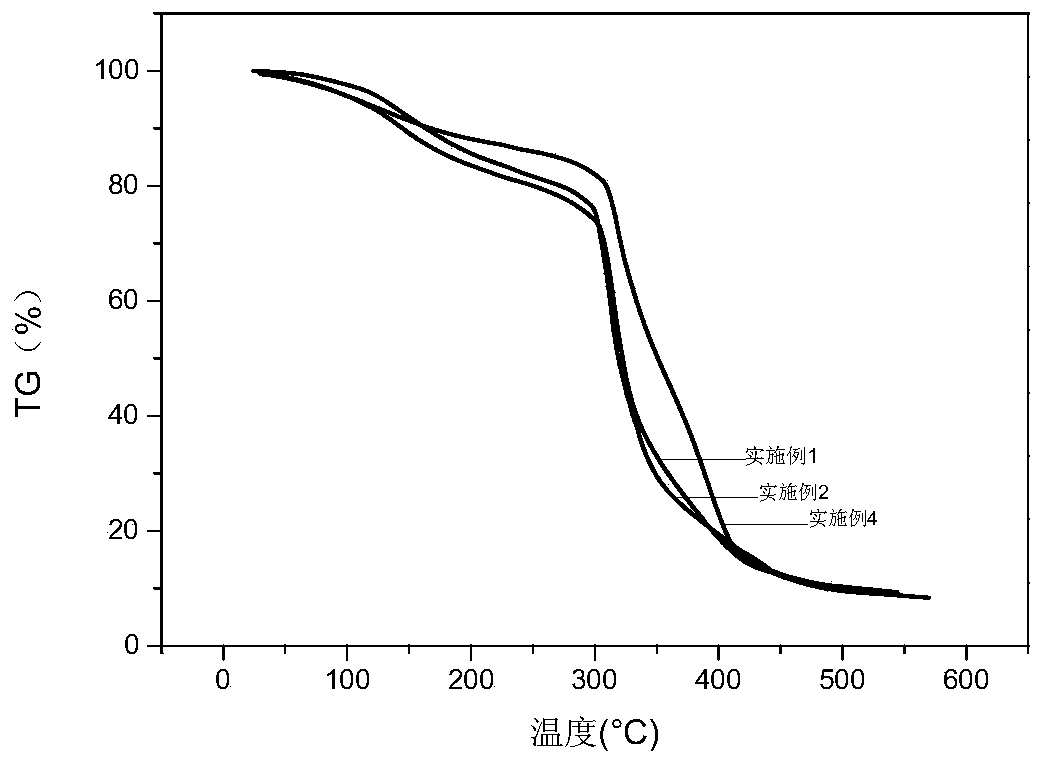

Embodiment 1

[0043] Put 17g (0.1mol) of isophoronediamine in a water bath at normal temperature, and add 37g (0.4mol) of epichlorohydrin dropwise at a rate of 20 drops / min while stirring, and react at a constant temperature of 25°C for 4 hours in a water bath. Then add 36.8g (0.4mol) of glycerol and 0.32g of boron trifluoride diethyl ether in sequence, then add 111g (1.2mol) of epichlorohydrin dropwise at a rate of 50 drops / min, and then raise the temperature to 50°C for constant temperature reaction 5h, then dropwise add 160g (1.6mol) sodium hydroxide solution (concentration is 40%) when cooling to 45°C, continue constant temperature reaction for 2h, finally add the mass ratio of 1:1 potassium dihydrogen phosphate (concentration is 20%) ) solution and acetic acid (60% concentration) to neutralize the product to a neutral pH. The upper product is subjected to rotary distillation to evaporate unreacted epichlorohydrin and residual water, and the epoxy leather tanning agent is obtained after...

Embodiment 2

[0046] Put 17g (0.1mol) of isophoronediamine in a water bath at normal temperature, add 37g (0.4mol) of epichlorohydrin dropwise at a rate of 25 drops / min while stirring, and react at a constant temperature for 2 hours in a water bath at 30°C. Then add 160g (0.4mol) of polyethylene glycol 400 and 0.71g of boron trifluoride ethyl ether in sequence, then add 74g (0.8mol) of epichlorohydrin dropwise at a rate of 60 drops / min, and heat up to 60°C after the dropwise addition React at constant temperature for 4 hours, then add dropwise 120g (1.2mol) sodium hydroxide solution (concentration 40%) when cooling to 30°C, continue constant temperature reaction for 3 hours, and finally add potassium dihydrogen phosphate (concentration 20% ) solution and acetic acid (concentration 50%) to neutralize the product to a neutral pH value. The upper product is subjected to rotary distillation to evaporate unreacted epichlorohydrin and residual water, and the epoxy leather tanning agent is obtaine...

Embodiment 3

[0049] Put 17g (0.1mol) of isophoronediamine in a water bath at room temperature, add 46.2g (0.5mol) of epichlorohydrin dropwise at a rate of 20 drops / min while stirring, and react at a constant temperature for 3 hours in a water bath at 30°C , then add 27.6g (0.3mol) glycerol and 0.45g tetrabutylammonium bromide successively, then dropwise add 92.52g (1.0mol) epichlorohydrin at a speed of 60 drops / minute, and heat up to 55 ℃ constant temperature reaction for 4 hours, and then dropwise added 151g (1.35mol) potassium hydroxide solution (concentration 50%) when cooling to 25 ℃, continued constant temperature reaction for 4 hours, and finally added sodium dihydrogen phosphate (concentration 20% concentration) with a mass ratio of 5:1 %) solution and acetic acid (concentration 50%) to neutralize the product to a neutral pH value. The upper product is subjected to rotary distillation to evaporate unreacted epichlorohydrin and residual water, and the epoxy leather tanning agent is o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com