Low-odor sterilizing micro-foaming spray-free polypropylene composite material and preparation method thereof

A composite material and micro-foaming technology, which is applied in the field of micro-foaming spray-free polypropylene composite material and its preparation, can solve the problem of adding limit and the like, and achieves low saturated water absorption, excellent mechanical properties and good adhesion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

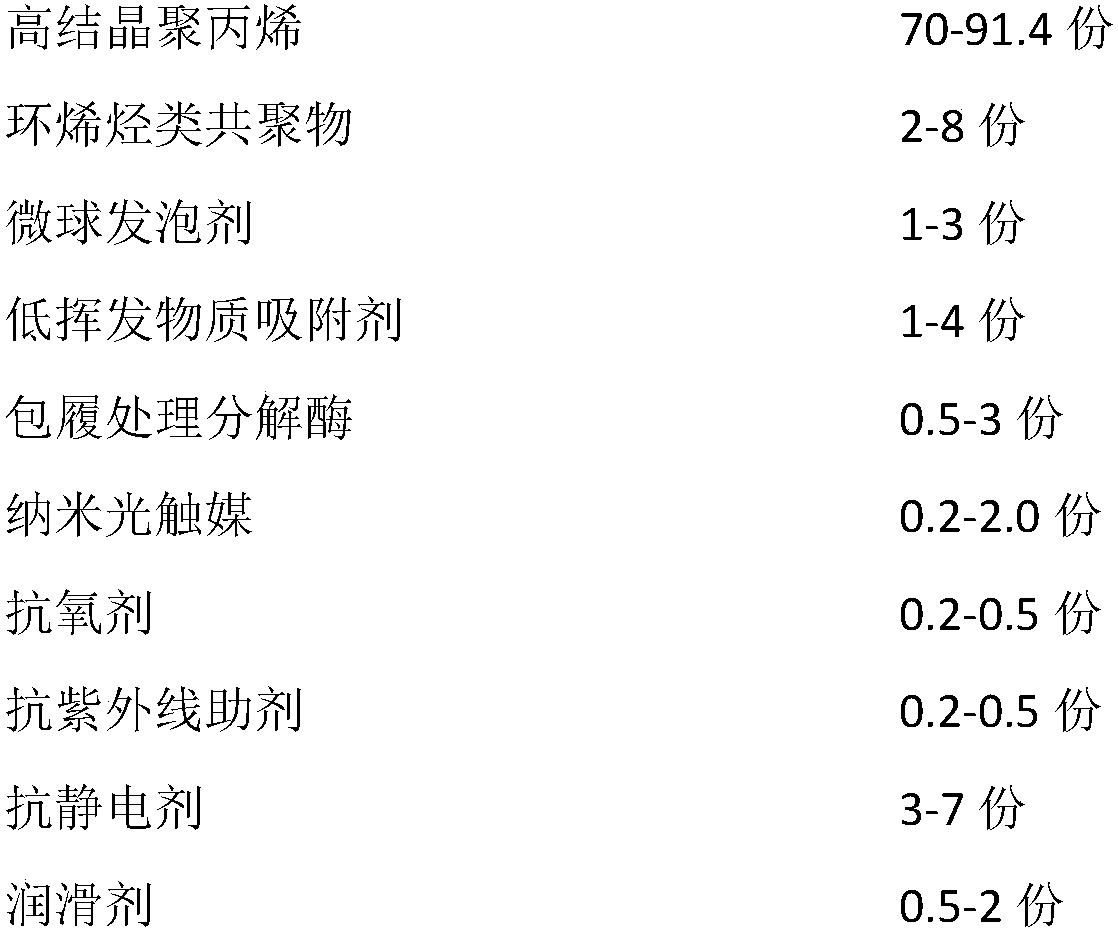

Method used

Image

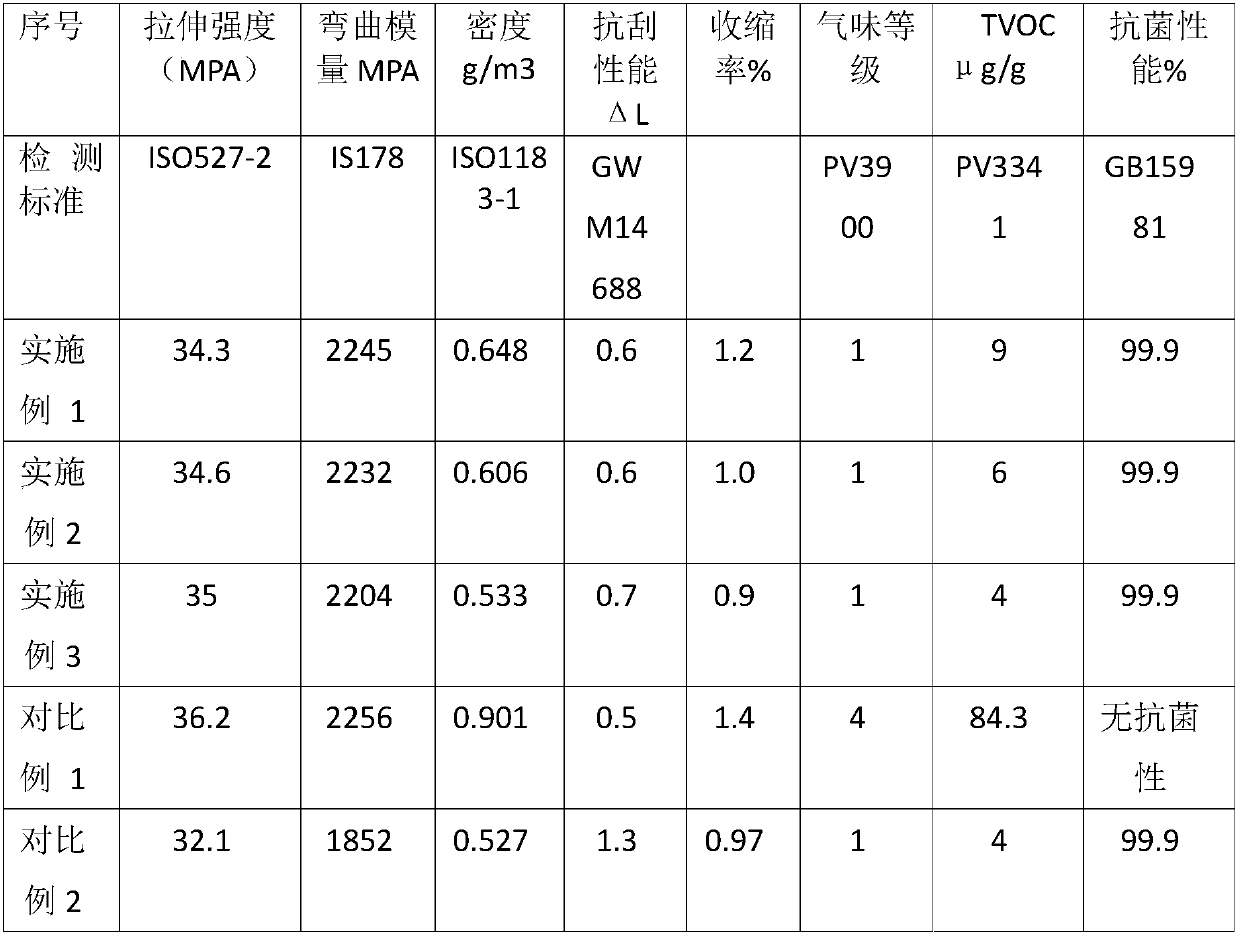

Examples

Embodiment 1

[0046] (1) First, antistatic agent (PELESTAT 300), low-volatile matter adsorbent (nano-silica, zeolite molecular sieve and calcined diatomaceous earth are mixed in a mass ratio of 1:2:1), and encapsulation treatment decomposing enzyme and nano photocatalyst were dried separately for use.

[0047] (2) 83.8 parts of high crystalline polypropylene and 6 parts of cycloolefin copolymer (COC), 1.5 parts of dried low-volatile matter adsorbent, antioxidant (antioxidant 1010, DSTP and high molecular weight sulfide The mass ratio of ester 412S is 0.2:0.1:0.1 mixed composition) 0.4 parts, UV770 anti-ultraviolet additive 0.3 parts, dried antistatic agent (PELESTAT 300) 5 parts, lubricant (silicone masterbatch) 1 part , added to the high mixer one by one, and mixed for 6 minutes to get the mixture A, referred to as component A.

[0048] (3) Mix 0.5 part of the decomposing enzyme of the dried package shoe treatment and 0.3 part of the nano photocatalyst together to obtain the mixture B, re...

Embodiment 2

[0052] (1) Antistatic agent (bis(β-hydroxyethyl) cocoamine), low-volatile matter adsorbent (nano-silica, zeolite molecular sieve and calcined diatomite are mixed in a mass ratio of 0.5:3:1.5) Mixed composition), packaged decomposing enzymes, and nano photocatalysts were dried separately for use.

[0053] (2) 82.7 parts of high crystalline copolymerized polypropylene and 6 parts of cycloolefin copolymer (COC), 1.7 parts of dried low-volatile matter adsorbent, antioxidant (antioxidant 1010, DSTP and high molecular weight sulfur Substitute ester 412S (mixed by mass ratio 0.2:0.:0.2) 0.4 parts, UV788 anti-ultraviolet additive 0.3 parts, dried antistatic agent (bis(β-hydroxyethyl) cocoamine) 5 parts, Add 1 part of lubricant (calcium stearate) into the high-speed mixer in sequence, and mix for 6 minutes to obtain compound A, referred to as component A.

[0054] (3) Mix 0.8 part of the decomposing enzyme and 0.5 part of the nano-photocatalyst that have been dried to obtain the mixtu...

Embodiment 3

[0058] (1) First, antistatic agent (PELESTAT 300), low volatile matter adsorbent (nano-silica, zeolite molecular sieve and calcined diatomaceous earth are mixed at a mass ratio of 1.5:1:0), and the package is decomposed Enzymes and nanophotocatalysts were dried separately for use.

[0059] (2) 81.7 parts of high crystalline polypropylene and 6 parts of cycloolefin copolymer (COC), 2 parts of dried low-volatile matter adsorbent, antioxidant (antioxidant 1010, DSTP and high molecular weight sulfide The mass ratio of ester 412S is 0.2:0.1:0.1 mixed composition) 0.4 parts, UV770 anti-ultraviolet additive 0.3 parts, dried antistatic agent (PELESTAT 300) 5 parts, lubricant (silicone masterbatch) 1 part , added into the high mixer one by one, and mixed for 8 minutes to get the mixture A, referred to as component A.

[0060] (3) Mix 1 part of the decomposing enzyme for bag-shoe treatment that has been dried and 0.6 part of the nano-photocatalyst together to obtain the mixture B, refe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com