Device and method for non-resistance drying of rice-grade silicon carbide ceramic green body by gel injection molding

A technology of gel injection molding and silicon carbide ceramics, which is used in the drying of ceramic products, ceramic molding machines, drying chambers/containers, etc., can solve the problem of increasing friction between wet blanks and supporting components, high water content, and difficult drainage process and other problems, to achieve the effect of preventing damage caused by excessive local stress and increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

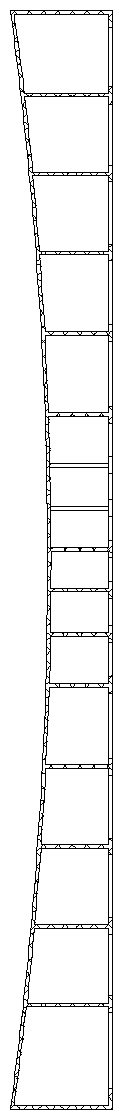

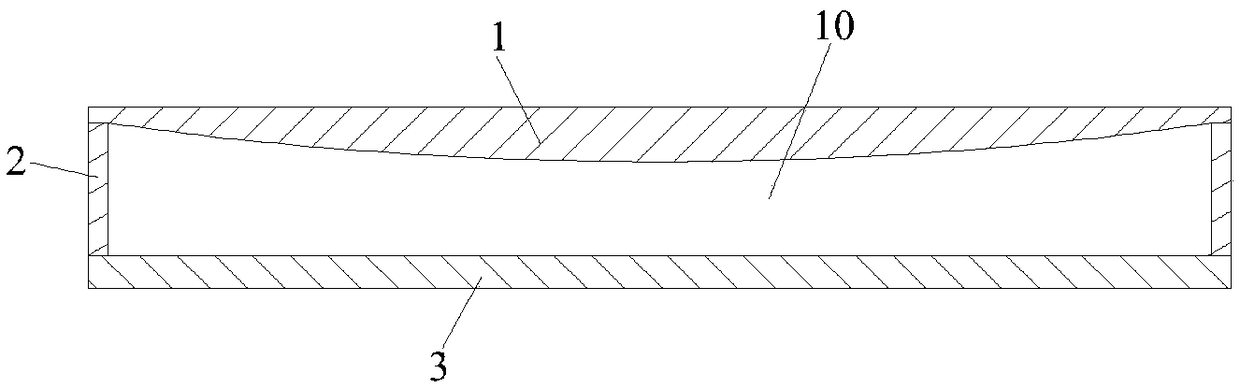

[0033] The non-resistance drying method for gel injection molding silicon carbide ceramic biscuits above meter level provided by the embodiment of the present invention includes the following steps:

[0034] Step 1: According to the authorized announcement number CN101941231B, the name is: the method introduced in the gel injection molding process specification of large-scale complex shape silicon carbide ceramic green body to prepare the φ3m silicon carbide ceramic green body; specifically, refer to the authorized announcement number CN101941231B and the name is : Part 0022 to 0033 of the gel injection molding process specification for large-sized and complex-shaped silicon carbide ceramic blanks.

[0035] Step 2: Move the φ3m silicon carbide ceramic green body into the drying tooling, connect the panel, the outer frame and the back support plate into one, and fill the gap between the silicon carbide green body and the drying tooling with a silica gel pad, on the one hand, pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com