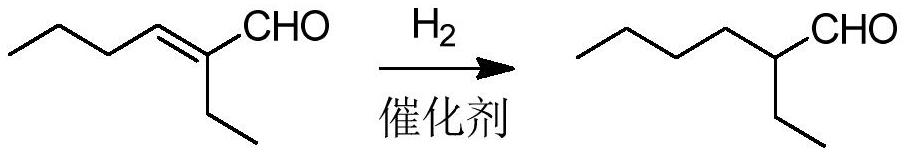

A kind of catalyst, its preparation method and the preparation method of 2-ethylhexanal

A technology of ethylhexanal and catalyst, which is applied in catalyst activation/preparation, preparation of organic compounds, preparation of carbon-based compounds, etc., can solve the problems of low catalyst processing capacity and high energy consumption in the separation process, and achieve the suppression of decarbonization by-products. , the effect of increasing the processing capacity and reducing the cost of the catalyst

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

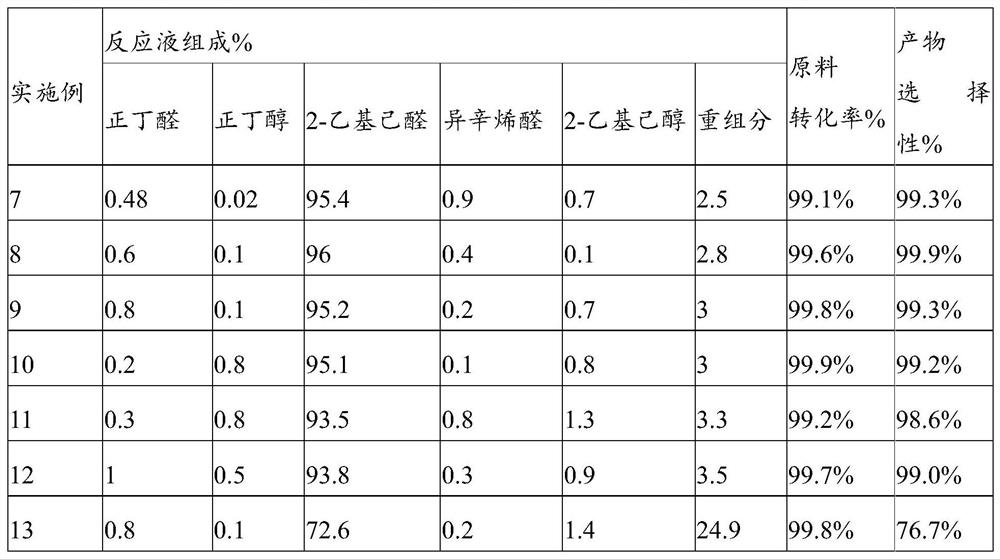

Examples

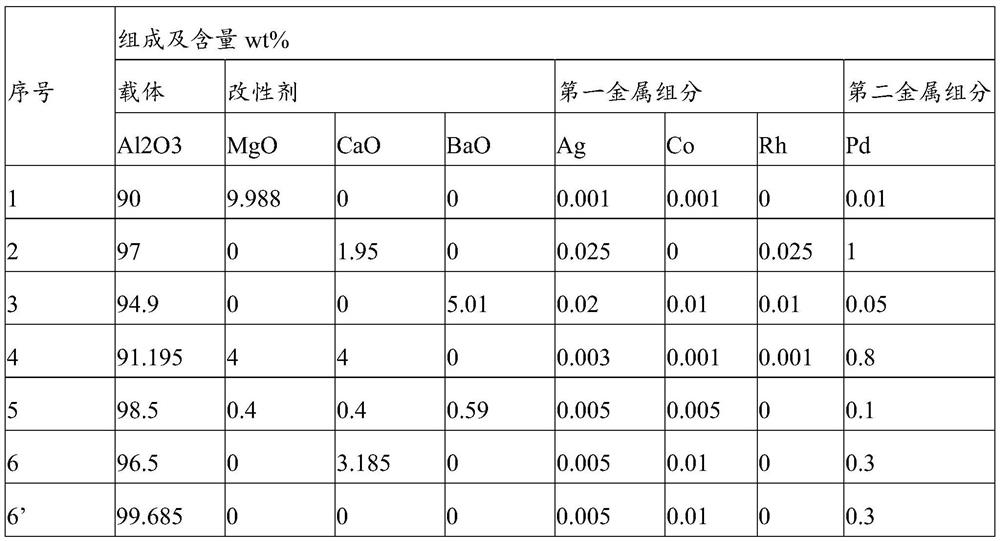

Embodiment 1

[0048]235.3 g of trichloride, 23.6 g of magnesium chloride dissolved with 4919 g of water, an aqueous solution of a total mass concentration of 5%, warmed to 40 ° C, add 12% ammonia water, such as aqueous solution, to be aqueous solution pH value to 8-9 The addition of ammonia water was stopped, stirred from 30 min to 60 ° C, stop stirring, deposition of aging for 1 h, washed by filtration, adding a solid amount of about 5% to about 5%, after molding, drying at 90 ° C for drying 24h The catalyst carrier was obtained by high temperature at 1000 ° C for 12 h.

[0049]0.0015gagno3And 0.005GCO (NO3)2· 6h2O was dissolved with 325 g of water, and the total mass concentration of 0.002% nitrate solution was mixed with the previously obtained carrier, 25 wt% NaOH aqueous solution was added to the solution, allowing the solution pH at 7.5-8, at 30 ° C for 1 h. After the obtained suspension was centrifuged, the resulting solid was dried at 90 ° C for 48 h, and then heated at 300 ° C for 12 h, and...

Embodiment 2

[0052]253.6 g of aluminum chloride, 3.86 g of calcium chloride was dissolved with 4034 g of water, which was equipped with a solution of a total mass concentration of 6%, warmed to 40 ° C, adding 12% ammonia water, such as aqueous solution, and the pH of the solution reached 8 The addition of ammonia water is stopped, stirred by stirring to 60 ° C, stop stirring, and then discospect 1H, washed by filtration, adding the amount of a solid of about 5% to 5%, after molding, after 100 ° C After drying 24 h, it was calcined at a high temperature of 1000 ° C for 12 h to obtain a catalyst carrier.

[0053]0.04gagno3And 0.07 g rh (no3)3It was dissolved with 274 g of water, and the total mass concentration of 0.04% nitrate solution was mixed, and 25 wt% NaOH aqueous solution was added to the solution, and the solution pH was added to 7.5-8, at 40 ° C for 1 h, After the obtained suspension was centrifuged, the resulting solid was dried at 100 ° C for 40 h, and then heated at 400 ° C for 12 h to o...

Embodiment 3

[0056]248.1 g of aluminum chloride and 7.98 g of chloride were dissolved using 3402 g of water, and the total mass concentration of 7% aqueous solution was stirred up to 40 ° C, and the pH of aqueous solution was 10 ° C, and the pH of the solution reached 8. The addition of ammonia water is stopped between the -9, stirred at 40 min, and the temperature is lowered, stop stirring, and then the aging of the aging 1.5H, after filtration, the amount of the solid% of the solids of about 5%, after molding, after molding, at 100 ° C It was dried for 36 h, and then 10 h was calcined at 1100 ° C to obtain a catalyst carrier.

[0057]0.031gagno3And 0.05gco (NO3)2· 6h2O and 0.028G RH (NO3)3It was dissolved with 272 g of water, and the total mass concentration of 0.04% nitrate solution was mixed with the previously obtained carrier, 25 wt% NaOH aqueous solution was added to the solution, allowing the solution pH at 7.5-8, at 40 ° C for 1 h, After the obtained suspension was centrifuged, the resulti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com