Catalyst for catalytic hydrodechlorination and preparation method and application thereof

A catalytic hydrogenation and catalyst technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the problems of poor catalyst stability, low conversion rate, short life, etc. problem, to achieve the effect of good stability, low cost and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

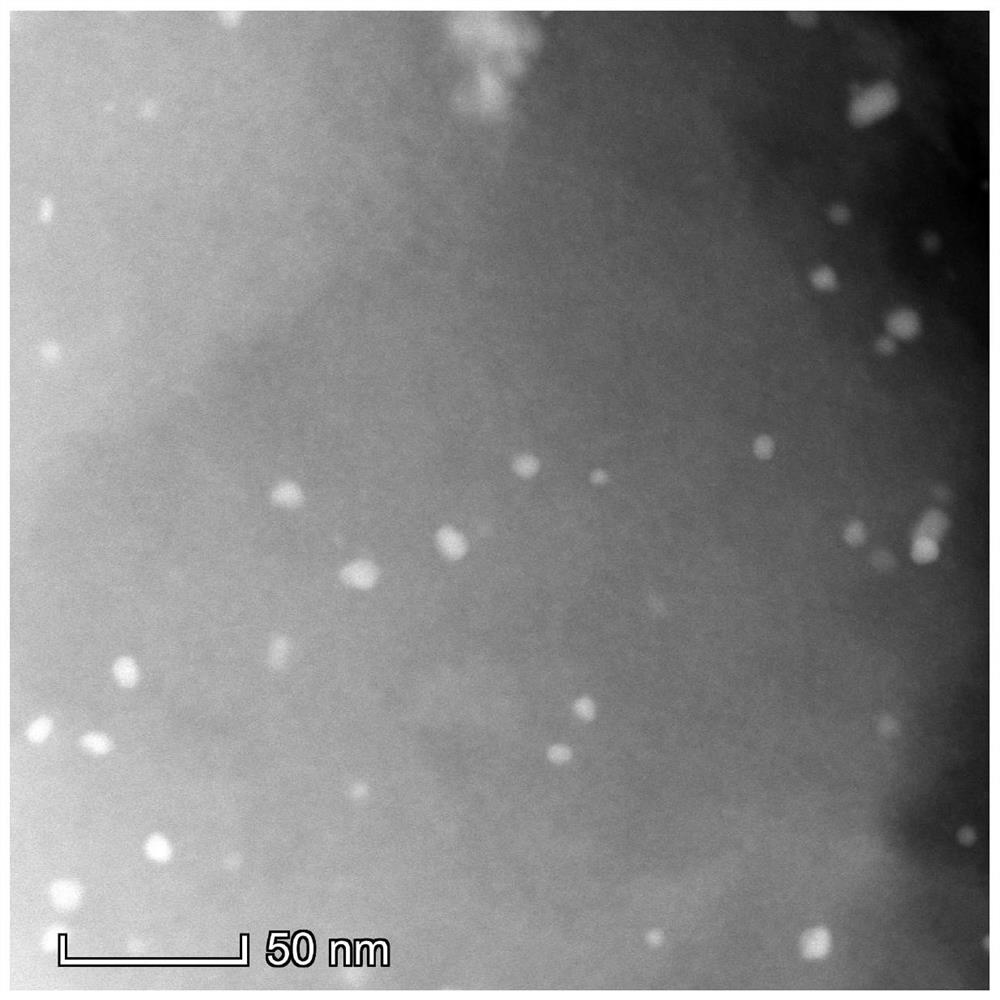

[0036] Prepare Ru / AC catalyst, comprises the following steps:

[0037] Take by weighing ruthenium chloride (purity Ru ≥ 37%) 0.027g, add 20mL dehydrated alcohol, after treating that ruthenium chloride dissolves completely, add the ethanol solution of 1mL sodium acetate in the alcoholic solution of ruthenium chloride (the concentration of sodium acetate is 0.5mol / L), put the mixed solution into a hydrothermal kettle, seal the hydrothermal kettle and transfer it to a constant temperature drying oven at 80°C for heat treatment for 2 hours to obtain a metal solution containing colloidal Ru. The obtained metal solution containing colloidal Ru was impregnated onto the surface of 1.0 g of activated carbon carrier (the activated carbon carrier was purchased from Hainan Coconut Ball Industry Co., Ltd., and the specific surface area was 1235m 2 / g, the most probable pore diameter is 8.96nm, the ash content is 7.8%, the same below), after ultrasonic impregnation for 15min, put it in an o...

Embodiment 2

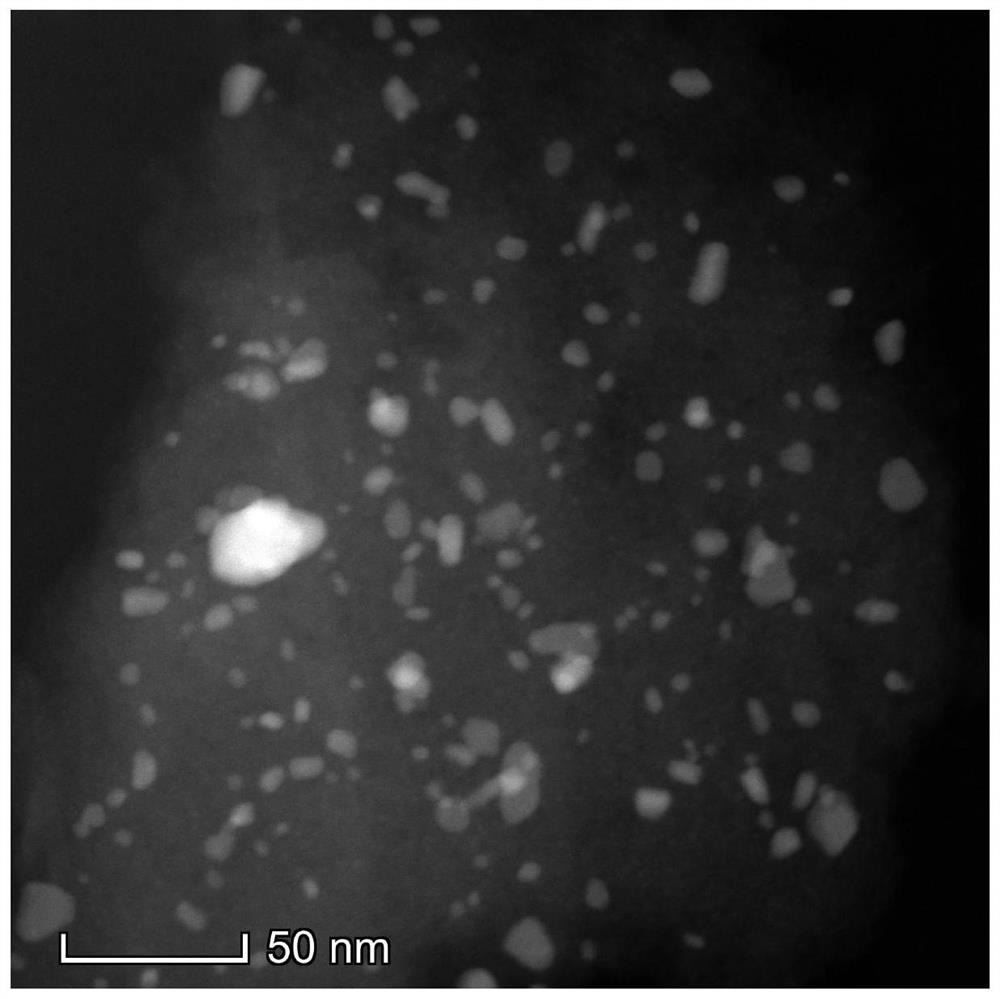

[0039] Preparation of Ru-B amorphous alloy catalyst comprises the following steps:

[0040] Weigh 0.032 g of ruthenium carbonyl, add 20 mL of absolute ethanol, and after the ruthenium carbonyl is completely dissolved, add 0.5 mL of ethanol solution of sodium acetate to the alcoholic solution of ruthenium carbonyl (the concentration of sodium acetate is 0.5 mol / L), and add 0.029 g of sodium borohydride, put the mixed solution into a hydrothermal kettle, seal the hydrothermal kettle and transfer it to a 90°C constant temperature drying oven for heat treatment for 3 hours to obtain a colloidal Ru-B metal solution. The resulting colloidal Ru-B metal solution is impregnated onto the surface of 1.0g of silicon carbide (the specific surface area of silicon carbide is 80m 2 / g, the most probable pore diameter is 15.46nm, the same below), after ultrasonic impregnation for 15min, put it in an oven and dry it for 2h at 120°C, then wash it repeatedly with distilled water and absolute et...

Embodiment 3

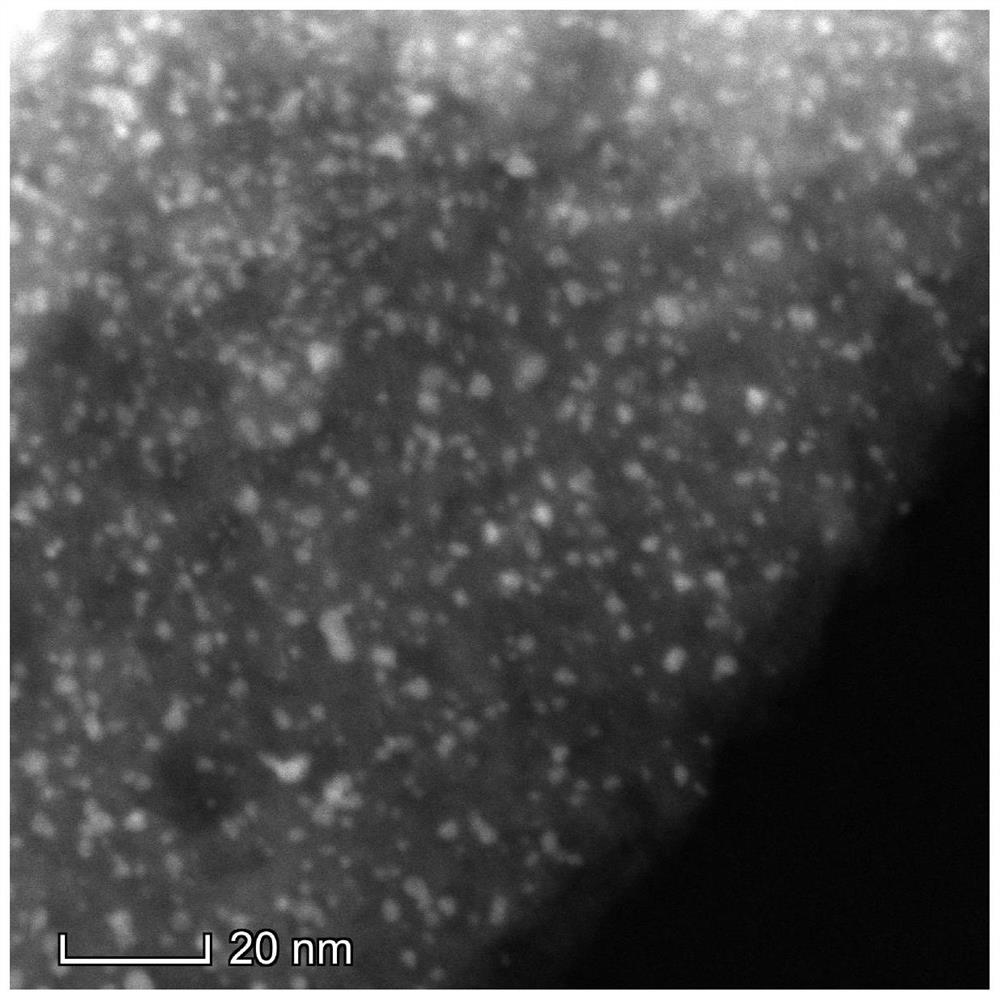

[0042] Preparation of Ru-B amorphous alloy catalyst comprises the following steps:

[0043] Weigh 0.054g of ruthenium chloride (purity Ru ≥ 37%), add 20mL of absolute ethanol, after the ruthenium chloride is completely dissolved, add 0.0378g of sodium borohydride to the alcohol solution of ruthenium chloride, put the mixed solution into In a hydrothermal kettle, seal the hydrothermal kettle and transfer it to a constant temperature drying oven at 100° C. for 4 hours to obtain a colloidal Ru-B metal solution. The resulting colloidal Ru-B metal solution is impregnated onto the surface of the carbon black carrier of 1.0g (the specific surface area of carbon black is 123m 2 / g, the most probable pore diameter is 6.88nm), after ultrasonic impregnation for 15min, put it in an oven and dry it at 120°C for 2h, then wash it repeatedly with distilled water and absolute ethanol to remove alkali metal ions, put it in an oven and dry it at 120°C . Afterwards, the dried catalyst was put...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com