Fire-preventing and fire-extinguishing colloid material, as well as preparation method and application thereof

A colloidal material, fire-fighting technology, applied in fire-fighting equipment and other directions, can solve the problems of increasing labor and cost of workers, large amount of base material and coagulant, endangering the health of miners, etc. Efficiency, improve the effective utilization rate, reduce the effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The present invention also relates to a preparation method of the above-mentioned fire extinguishing colloidal material, comprising: mixing the components uniformly.

[0044] Preferably, the method comprises:

[0045] 1). Mix the calcium salt and water according to the mass ratio of 4:43-49, fully stir for 5min-10min to form a solution, then add the sodium silicate, and fully stir for no less than 10min to obtain a mixture A;

[0046] 2). Mix the coagulant with the remaining amount of water, and stir fully for no less than 10 minutes to obtain mixture B;

[0047] 3). Mixing the mixture A with the mixture B;

[0048] Wherein, step 1) and step 2) have no sequence;

[0049] Preferably, the method comprises:

[0050] 1). Mix the calcium salt and water according to the mass ratio of 4:46, fully stir for 5min to 10min to form a solution, then add the sodium silicate, and fully stir for 10min to 15min to obtain mixture A;

[0051] 2). Mix the coagulant with the remaining a...

Embodiment 1

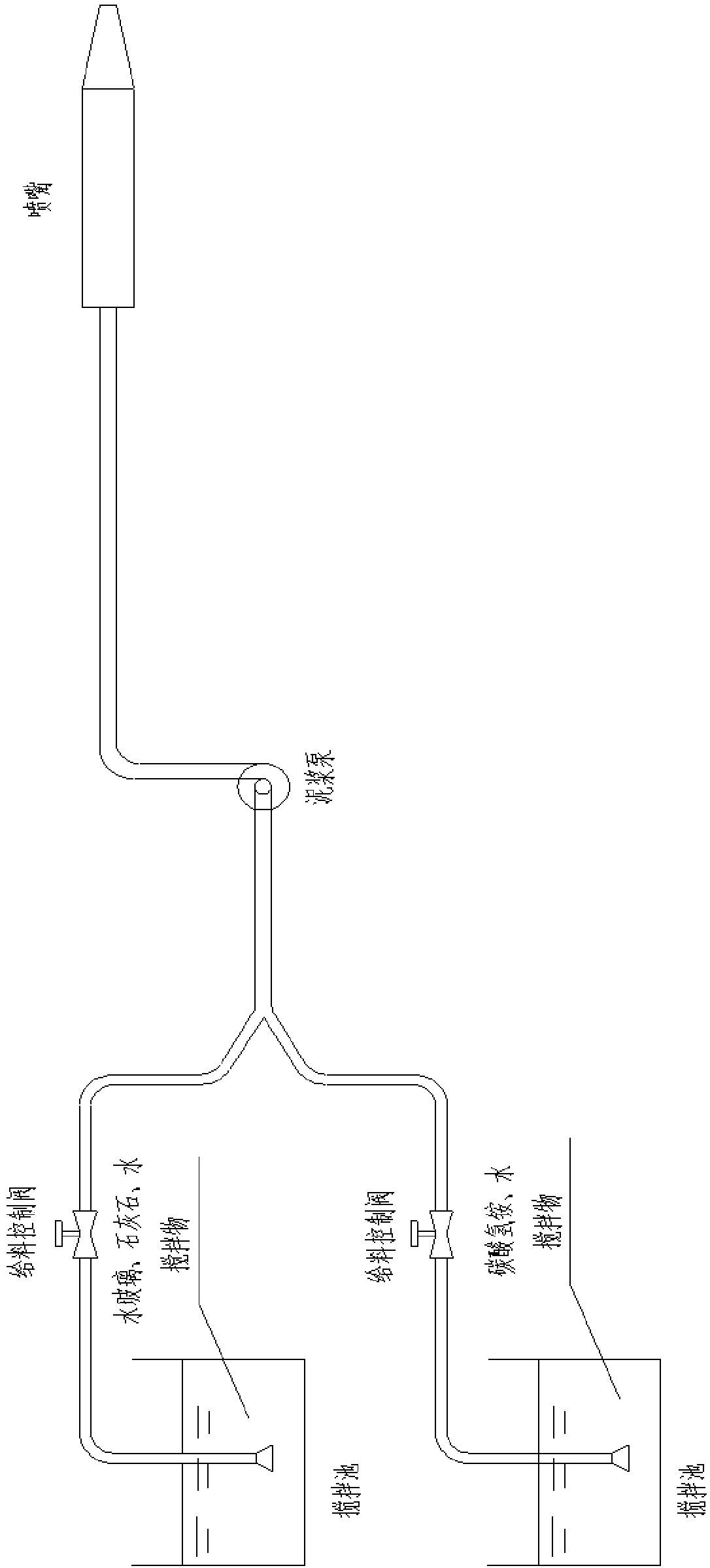

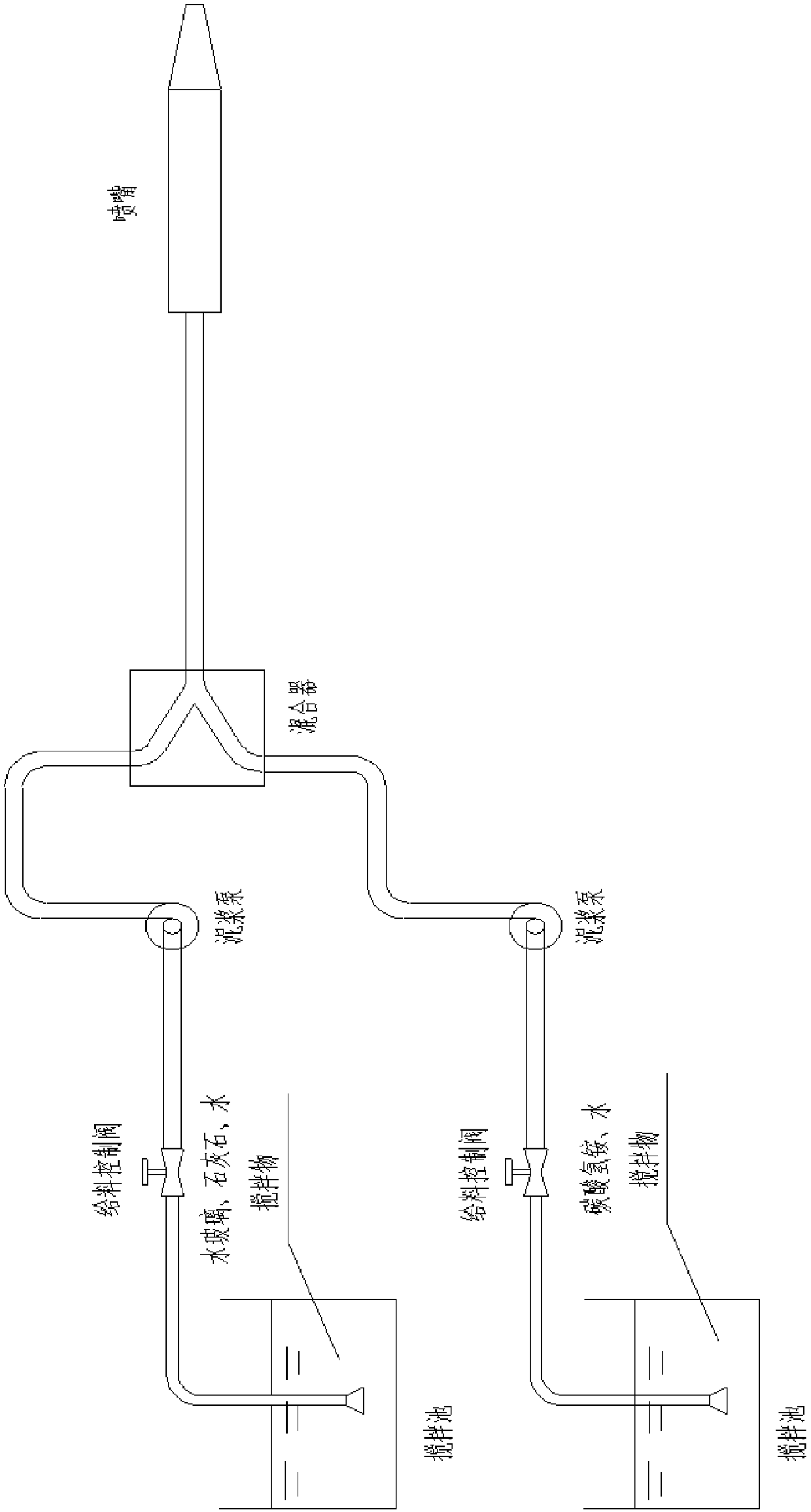

[0064] The anti-fire colloidal material of the present embodiment, the quality of its sodium silicate is 5g, and the quality of limestone is 7g, and the quality of ammonium bicarbonate is 3g, and water 85 parts; When configuring, as figure 1 As shown, limestone and water were mixed according to the mass ratio of 4:43, fully stirred for 5 minutes to form a solution, then the sodium silicate was added, and fully stirred for 10 minutes to obtain mixture A; ammonium bicarbonate was mixed with the remaining water, fully Mixture B was obtained by stirring for 10 minutes; after mixing the two solutions through a tee, the solution was sprayed onto the coal seam with a mud pump, and its performance indicators are shown in Table 1.

Embodiment 2

[0066] The anti-fire colloidal material of the present embodiment, the quality of its sodium silicate is 7g, and the quality of limestone is 5g, and the quality of ammonium bicarbonate is 5g, and water 83 parts; When configuring, as figure 1 As shown, limestone and water were mixed according to the mass ratio of 4:49, fully stirred for 10 minutes to form a solution, then the sodium silicate was added, and fully stirred for 15 minutes to obtain mixture A; ammonium bicarbonate was mixed with the remaining water, fully Mixture B was obtained by stirring for 15 minutes; after mixing the two solutions through a tee, the solution was sprayed onto the coal seam with a mud pump, and its performance indicators are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com