Lithographic printing original plate and plate making method

A technology for lithographic printing plates and original plates, which is applied in the directions of printing, printing process, and photolithography process of pattern surface. The effect of excellent durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0246] Hereinafter, although an Example demonstrates this invention in detail, this invention is not limited to this. In polymer compounds, unless otherwise specified, the molecular weight is the mass average molar mass (Mw) in terms of polystyrene based on the gel permeation chromatography (GPC) method, and the ratio of repeating units is the mole fraction. . In addition, the acid value is a value calculated by neutralization titration.

[0247] Hereinafter, synthesis examples of specific polymers and polymers for comparison are shown.

Synthetic example 1

[0248] (Synthesis Example 1: Synthesis of Specific Polymer A-1)

[0249] Specific polymer A-1 was synthesized according to the following reaction scheme.

[0250] In a 200 mL three-necked flask, 3.10 g (15.27 mmol) of isophthaloyl chloride as a difunctional acid chloride, 320 mg (3.05 mmol) of methacryloyl chloride as a monofunctional acid chloride, 2,2,6,6-tetra 25 mg of methylpiperidine-1-oxyl (TEMPO) and 37.5 g of N,N-dimethylacetamide (DMAc) were stirred at room temperature. As an acid chloride reactive bifunctional compound, a mixed solution of 6.57 g (15.27 mmol) of JEFFAMINE D-400 (manufactured by Huntsman Corporation), 3.40 g (33.6 mmol) of triethylamine, and 19.44 g of DMAc was prepared in a dropping funnel to react The above-mentioned mixed solution was dripped into the 3 necked flask so that the temperature of the liquid might become 30 degreeC or less. After stirring at room temperature for 1 hour, 1.0 g of methanol was added, followed by further stirring for 1 h...

Synthetic example 2~13

[0253] (Synthesis Examples 2 to 13: Synthesis of Specific Polymers A-2 to A-13)

[0254] Specific polymers A-2 to Solution of A-13 in 1-methoxy-2-propanol.

[0255]

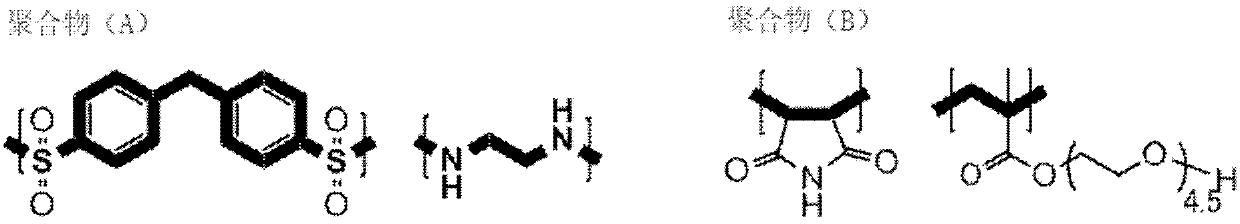

[0256] Each compound described in Table 1 is as follows.

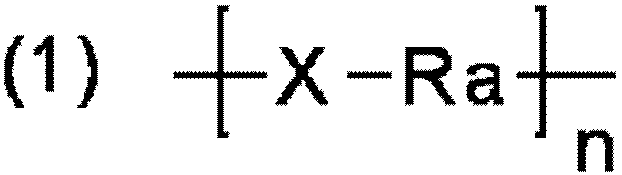

[0257] [chemical formula 12]

[0258]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com