High-voltage flexible solid super capacitor and preparation method thereof

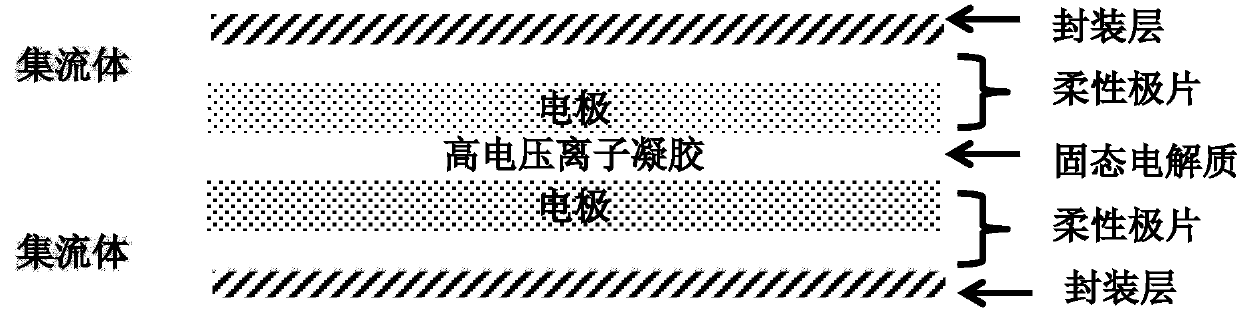

A supercapacitor, high-voltage technology, used in the manufacture of hybrid/electric double-layer capacitors, hybrid capacitor electrodes, hybrid capacitor electrolytes, etc., can solve problems such as liquid electrolyte leakage, avoid leakage hazards, improve energy density, and simplify packaging. The effect of craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] The steps of the preparation method of the present invention are as follows:

[0055] 1) Preparation of electrode active materials: Commercial carbon nanotubes or synthetic graphene-based porous carbon nanomaterials are used as electrode active materials.

[0056] The process of synthesizing graphene-based porous carbon nanomaterials is as follows: the natural graphite is oxidized to graphite oxide by the Hummers method, and an aqueous solution of graphene oxide is prepared by ultrasonic dispersion and exfoliation of a probe. Then add conductive polymer monomer, dopant and oxidant ammonium persulfate to the graphene oxide aqueous solution, and stir and react for 1-48 hours at a temperature of -10°C to 25°C to obtain a graphene oxide-conductive polymer composite material and washed dry. Grind and mix the above-mentioned graphene oxide-conductive polymer composite material and potassium hydroxide in a ratio of 2:1 to 1:8, put it into a tube furnace and activate it by cal...

Embodiment 1

[0078] 1) Preparation of electrode active materials

[0079] The natural graphite was oxidized to graphite oxide by the Hummers method, and a graphene oxide aqueous solution was prepared by probe ultrasonic dispersion and exfoliation. Then add 0.05molL to the graphene oxide aqueous solution -1 Aniline, 1mol L -1 of perchloric acid and 0.05molL -1 Ammonium persulfate, at a temperature of -10°C, stirred and reacted for 24 hours to obtain a graphene oxide-polyaniline composite material and washed and dried, such as image 3 shown.

[0080] Grind and mix the above compound and potassium hydroxide in a ratio of 1:4, put it into a tube furnace and calcinate to 700°C for activation under an argon atmosphere, then wash and dry with dilute hydrochloric acid at room temperature to obtain graphene-based porous carbon nano materials such as Figure 4 shown.

[0081] 2) Preparation of flexible electrode sheets

[0082] The above-mentioned graphene-based porous carbon nanomaterial is...

Embodiment 2

[0087] 1) Preparation of electrode active materials

[0088] The natural graphite was oxidized to graphite oxide by the Hummers method, and a graphene oxide aqueous solution was prepared by probe ultrasonic dispersion and exfoliation. Then add 0.005molL to the graphene oxide aqueous solution -1Ethylenedioxythiophene, 0.02molL -1 of camphorsulfonic acid and 0.005molL -1 Ammonium persulfate was stirred and reacted for 48 hours at a temperature of 0° C. to obtain a graphene oxide-polyethylenedioxythiophene composite material, which was washed and dried. Grind and mix the above compound and potassium hydroxide at a ratio of 1:8, put it into a tube furnace and calcinate to 700°C for activation under an argon atmosphere, then wash and dry with dilute hydrochloric acid at room temperature to obtain graphene-based porous carbon Composite nanomaterials;

[0089] 2) Preparation of flexible electrode sheets

[0090] With the above-mentioned graphene-based porous material as the acti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com