TiAl-based high-temperature-resistant self-lubricating composite and preparation method

A composite material and self-lubricating technology, applied in the field of materials, can solve the problems of limited material application, large friction coefficient and wear amount, and achieve the effects of improving mechanical properties, improving brittle defects, improving dry friction coefficient and wear rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

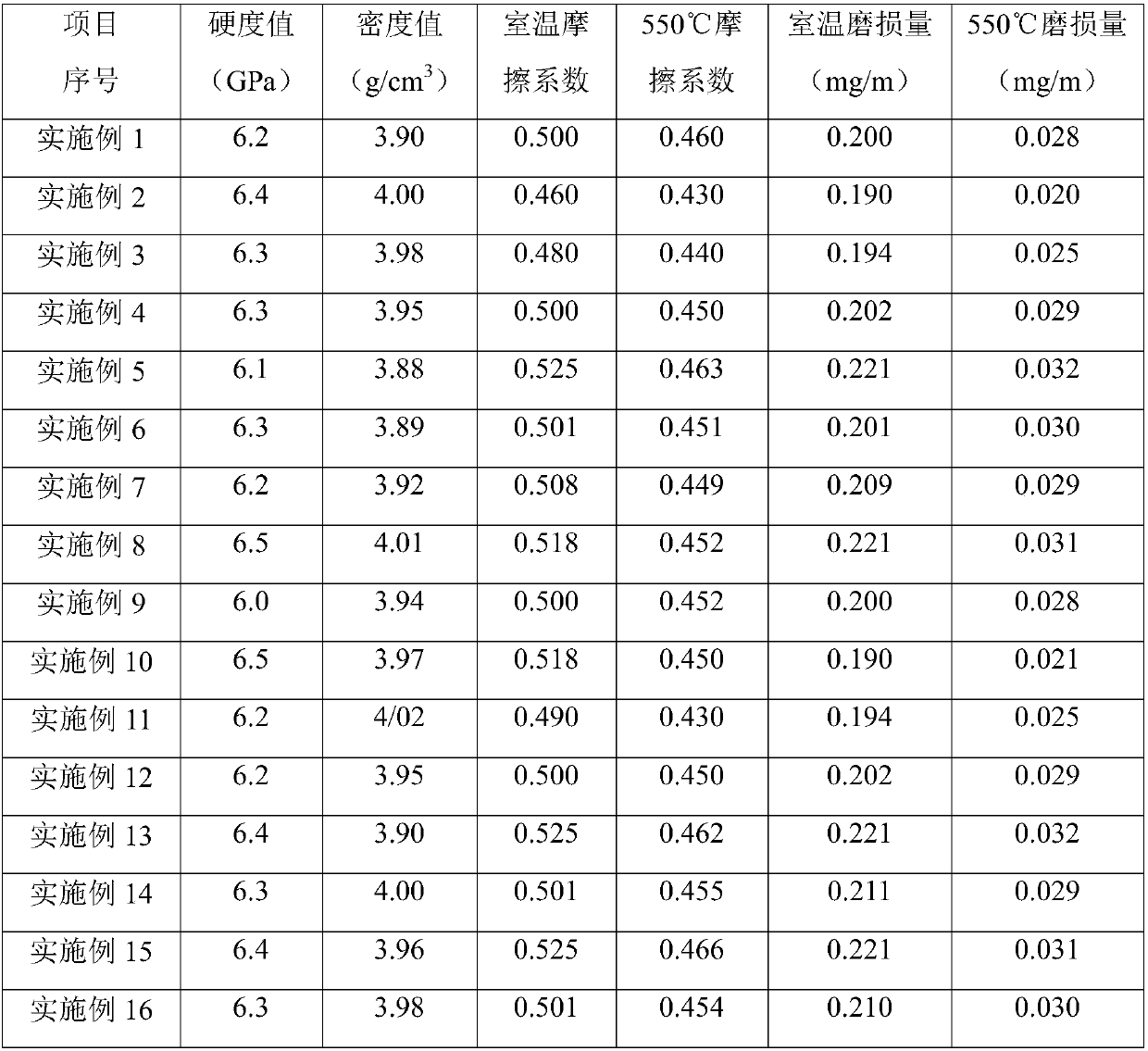

Examples

Embodiment 1

[0023] According to the mass percentage, add 30% Ti with a particle size of 40 mesh 3 SiC 2 , the rest is sintered TiAl alloy powder with a particle size of 300 mesh, the mass percent of the TiAl alloy powder composition is 20% Al powder, 1% Cr powder, and the rest is Ti powder, and the above powder is uniformly mixed by planetary ball mill , the mixing process is carried out in an argon atmosphere, alcohol is used as a dispersant, the amount added is 3ml per 100g of mixed powder, the ball-to-material ratio is 2:1, the speed of the ball mill is set to 300r / min, and the ball milling time is 1h (forward and reverse Alternate operation, once every 30 minutes); after drying the uniformly mixed powder, put it into a cylindrical mold for pre-press molding, the pressure is 25MPa, the holding time is 10s, and then the pre-press block is dried; for the dried SPS sintering is performed on the pre-pressed block, the pressure is 20MPa, the vacuum degree is 10Pa, heated to 800°C, kept for...

Embodiment 2

[0025] According to the mass percentage, add 5% Ti with a particle size of 80 mesh 3 SiC 2 , the rest is sintered TiAl alloy powder with a particle size of 300 mesh, the mass percent of the TiAl alloy powder composition is 20% Al powder, 3% Cr powder, and the rest is Ti powder, and the above powder is uniformly ball-mixed by a planetary ball mill , the mixing process is carried out in an argon atmosphere, alcohol is used as a dispersant, the addition amount is 5ml per 100g of mixed powder, the ball-to-material ratio is 2:1, the ball mill speed is set to 300r / min, and the ball milling time is 2h (forward and reverse Alternate operation, once every 30 minutes); after drying the uniformly mixed powder, put it into a cylindrical mold for pre-press molding, the pressure is 25MPa, the holding time is 10s, and then the pre-press block is dried; for the dried SPS sintering is performed on the pre-pressed block, the pressure is 20MPa, the vacuum degree is 10Pa, heated to 1000°C, kept ...

Embodiment 3

[0027] According to the mass percentage, add 20% Ti with a particle size of 80 mesh 3 SiC 2 , the rest is sintered TiAl alloy powder with a particle size of 100 mesh, the mass percent of the TiAl alloy powder composition is 20% Al powder, 1% Cr powder, and the rest is Ti powder, and the above powder is uniformly ball-mixed by a planetary ball mill , the mixing process is carried out in an argon atmosphere, alcohol is used as a dispersant, the amount added is 5ml per g of mixed powder, the ball-to-material ratio is 2:1, the speed of the ball mill is set to 400r / min, and the ball milling time is 3h (forward and reverse Alternate operation, once every 30 minutes); After drying the uniformly mixed powder, put it into a cylindrical mold for pre-press molding, the pressure is 10MPa, the holding time is 10s, and then the pre-press block is dried; for the dried SPS sintering is performed on the pre-pressed block, the pressure is 20MPa, the vacuum degree is 10Pa, heated to 1200°C, kep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com