The method of synthesizing dimethyl carbonate

A technology of dimethyl carbonate and ethylene carbonate, which is applied in the field of synthesizing dimethyl carbonate, can solve the problems of poor catalyst activity and easy loss of active components, and achieve the effects of stable properties, easy loss and difficult loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

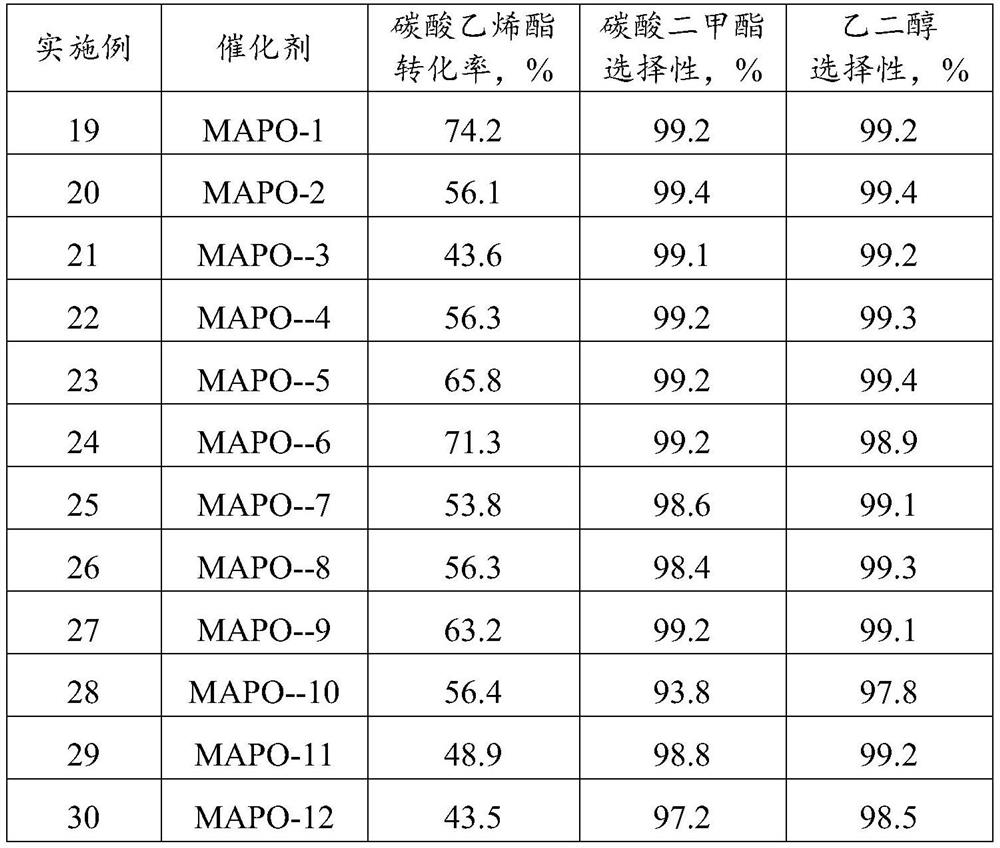

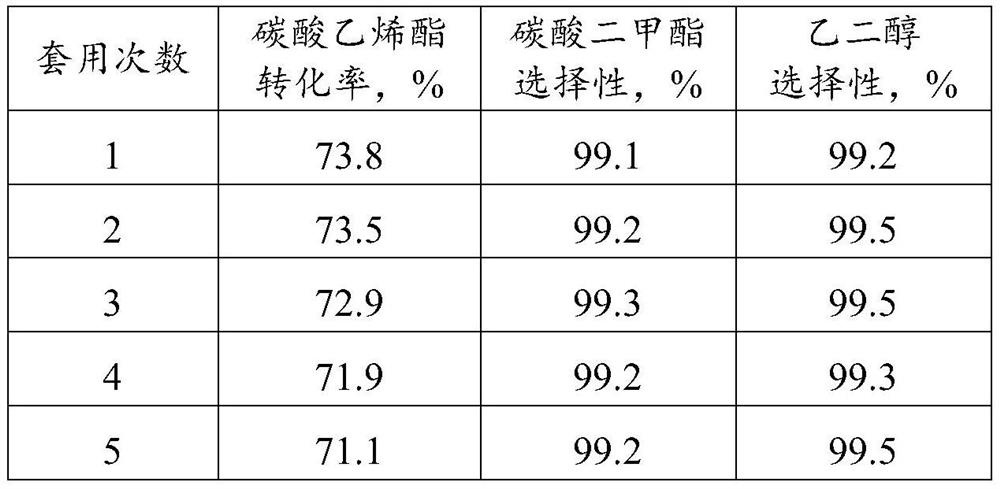

Examples

Embodiment 1

[0016] Preparation of aluminum phosphate aluminum oxide APO: Dissolve 58.8g aluminum nitrate and 22.3g diammonium hydrogen phosphate in 500ml deionized water at room temperature, stir for 1 hour, add 10ml concentrated nitric acid for acidification, continue to drop concentrated ammonia water to adjust the pH value to 8 , filter the formed precipitate, wash with deionized water for 3 times, dry at 120°C overnight, and then dry and roast at 500°C to obtain phosphorus aluminum oxide APO-1, determined by ICP-AES, the content of Al in APO-1 Take Al 2 o 3 Calculated as 40%, the content of P is P 2 o 5 Count as 60%.

Embodiment 2

[0018] The preparation steps of aluminophosphate APO are the same as in [Example 1], except that the amounts of aluminum nitrate and diammonium hydrogen phosphate used are respectively 14.7g and 33.5g to obtain aluminophosphate APO-2, which is determined by ICP-AES. The content of Al in -2 is expressed as Al 2 o 3 Calculated as 10%, the content of P is P 2 o 5 Count as 90%.

Embodiment 3

[0020] The preparation steps of aluminophosphate APO are the same as in [Example 1], except that the amounts of aluminum nitrate and diammonium hydrogen phosphate used are respectively 36.8g and 27.9g to obtain aluminophosphate APO-3, which is determined by ICP-AES. The content of Al in -3 is expressed as Al 2 o 3 Calculated as 25%, the content of P is P 2 o 5 Count as 75%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com