Reactor and method capable of improving biodegradability of difficult-to-degrade organic sewage

A technology of organic sewage and reactors, applied in chemical instruments and methods, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as unstable effects and anaerobic sludge loss, and achieve improved reliability Biochemical properties, reduced impact, and improved mass transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

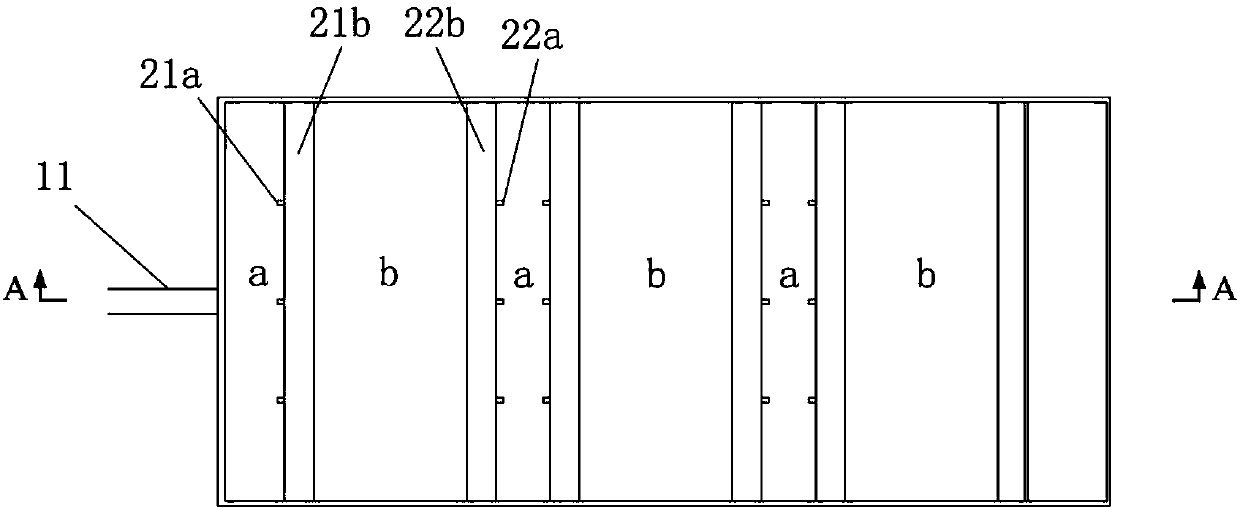

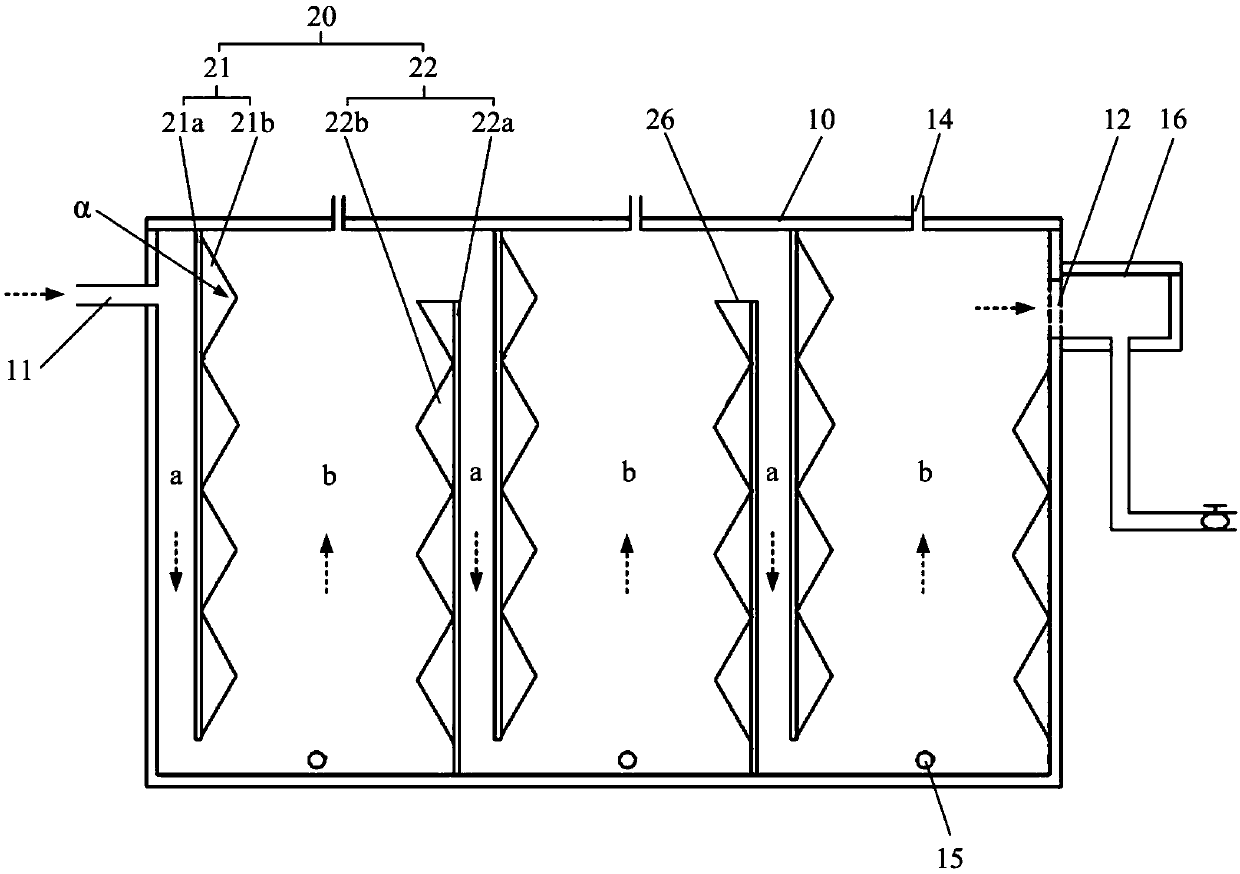

[0024] Example 1: Combining figure 1 and figure 2 Illustrate the reactor of the present invention that can improve the biodegradability of refractory organic sewage. The reactor 10 of this embodiment is a box in the shape of a cuboid. The top of the left side wall of the reactor 10 is provided with a water inlet 11. The top of the wall is provided with a water outlet 12, and three baffle assemblies 20 are arranged side by side and spaced apart in the housing of the reactor 10, and the arrangement direction of the three baffle assemblies 20 is consistent with the water flow direction in the reactor 10 ( figure 1 The direction indicated by the arrow in the dotted line is the sewage water flow direction); each baffle assembly 20 includes vertical and spaced guide baffles 21 and baffles 22, and the guide baffles 21 and baffles 22 All are corrugated plates; in each baffle assembly 20, the top of the diversion baffle 21 near the water inlet 11 is connected to the top of the reacto...

Embodiment 2

[0032] Embodiment 2: Combination figure 1 Illustrate a kind of method that can improve the biodegradability of refractory organic sewage of the present invention, concrete steps are as follows:

[0033] Using the reactor 10 described in Example 1, the bottom of the reactor 10 is filled with an appropriate amount of volcanic rock, and the upper part of the volcanic rock is provided with an elastic three-dimensional filler. The sludge is obtained from the anaerobic hydrolysis tank of a sewage treatment plant for film-hanging domestication and sent into the reaction The reactor 10 uses a peristaltic pump to draw the pretreated sewage into the reactor 10 through the water inlet, and the sewage passes through three diversion chambers a and three anaerobic hydrolysis reaction chambers formed by three baffle assemblies 20 in sequence, so that The sewage and the elastic three-dimensional filler are fully stirred and contacted and reacted. The purified water is discharged from the reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com