Industrial Wastewater Treatment Methods

A treatment method and technology for industrial sewage, applied in water/sewage treatment, water/sewage treatment equipment, water/sludge/sewage treatment, etc., can solve the problem of untimely discharge of flocs, overload of sludge in sedimentation tanks, and collection efficiency Low problems, to achieve the effect of improving sewage purification effect, reducing operation process and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

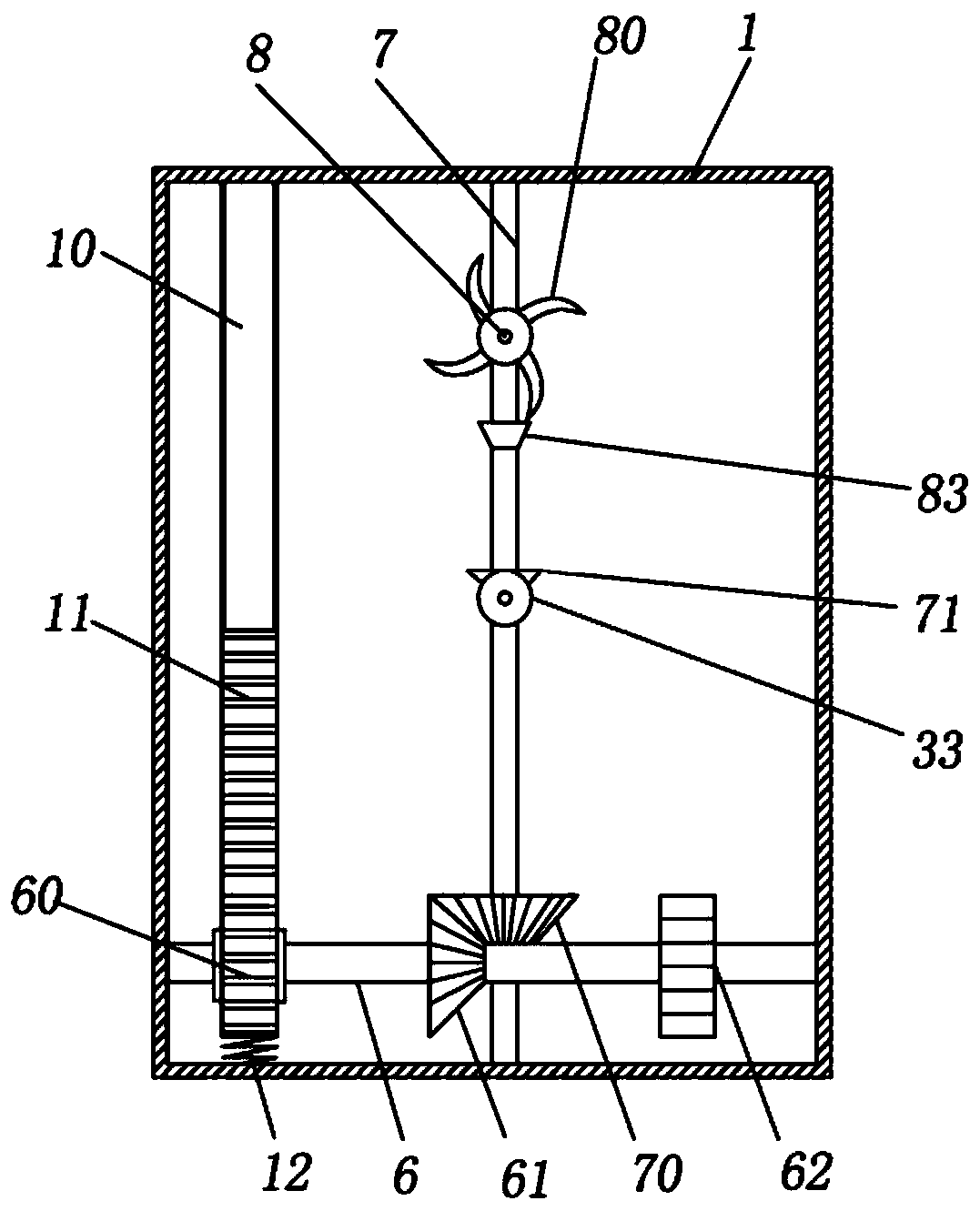

[0027] The embodiment is basically as attached figure 1 Shown:

[0028] The industrial sewage treatment method adopts a coagulation machine for coagulation treatment, and the coagulation machine includes an outer bucket 1 and an inner bucket 2; a water injection pipe 20, a drainage pipe 21 and an interlayer 5 are arranged between the outer bucket 1 and the inner bucket 2. The water injection pipe 20 is connected between the top of the outer tub 1 and the top of the inner tub 2; the drain pipe 21 is installed on the bottom of the inner tub 2 and extends to the outside of the outer tub 1, and the drain pipe 21 is equipped with a drain valve 22.

[0029] A sliding rack 11 is slidably connected to the inner wall of the outer tub 1, and a specific sliding structure can be selected to provide a vertical chute 10 on the inner wall of the outer tub 1, so that the sliding rack 11 is clamped and slidably connected in the chute 10; and A reset member is connected between the sliding rac...

Embodiment 2

[0045] The difference between this example and Example 1 is that in step A, 100kg of aluminum sulfate, 10kg of ferrous sulfate and 20kg of polyacrylamide are mixed, and diluted with water to form a solution with a mass fraction of 20% for later use; in step B, the coagulant The volume is 1L, and the volume of sewage is 130L; the standing time in step D is 10min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com