Straw-fiber composite adsorption material and preparation method thereof

A composite adsorption material and straw fiber technology, which is applied in chemical instruments and methods, adsorption water/sewage treatment, and other chemical processes, can solve problems such as short service life and unstable performance of adsorption materials, and achieve excellent adsorption performance and reduce Swelling after absorbing water and increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

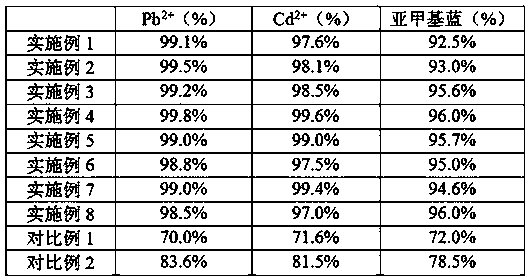

Examples

Embodiment 1

[0023] A straw fiber composite adsorption material, made of the following raw materials in parts by weight: 65 parts of straw, 40 parts of acrylic acid emulsion, 8 parts of nano calcium carbonate, 12 parts of polyethylene glycol, 8 parts of sepiolite powder, 10% silicon 50 parts of sodium nitrate solution, 5 parts of crosslinking agent, 0.2 part of initiator and 0.5 part of dibutyltin dilaurate.

[0024] Wherein the crosslinking agent is N, N-methylenebisacrylamide.

[0025] Wherein the initiator is sodium persulfate.

[0026] A preparation method of straw fiber composite adsorption material, comprising the following steps:

[0027] (1) Crush corn stalks to a particle size of 100 mesh, place them in high-temperature steam at 150°C for 60 minutes, add 2 times the weight of 1mol / L sodium hydroxide solution and soak for 12 hours;

[0028] (2) Then add acrylic emulsion, cross-linking agent, initiator and dibutyltin dilaurate, stir well and react at 60°C for 1 hour, then add nano...

Embodiment 2

[0031] A straw fiber composite adsorption material, made of the following raw materials in parts by weight: 68 parts of straw, 38 parts of acrylic acid emulsion, 9 parts of nano-calcium carbonate, 11 parts of polyethylene glycol, 9 parts of sepiolite powder, and 11% silicon 48 parts of sodium acid solution, 6 parts of crosslinking agent, 0.3 part of initiator and 0.4 part of dibutyltin dilaurate.

[0032] Wherein the crosslinking agent is N, N-methylenebisacrylamide.

[0033] Wherein the initiator is benzoyl peroxide.

[0034] A preparation method of straw fiber composite adsorption material, comprising the following steps:

[0035] (1) Crush corn stalks to a particle size of 120 mesh, place them in high-temperature steam at 140°C for 70 minutes, add 2.2 times the weight of 0.8mol / L sodium hydroxide solution and soak for 14 hours;

[0036] (2) Then add acrylic emulsion, cross-linking agent, initiator and dibutyltin dilaurate, stir well and react at 70°C for 0.8h, then add na...

Embodiment 3

[0039] A straw fiber composite adsorption material, made of the following raw materials in parts by weight: 70 parts of straw, 35 parts of acrylic acid emulsion, 10 parts of nano-calcium carbonate, 10 parts of polyethylene glycol, 10 parts of sepiolite powder, 12% silicon 45 parts of sodium nitrate solution, 7 parts of crosslinking agent, 0.4 part of initiator and 0.3 part of dibutyltin dilaurate.

[0040] Wherein the crosslinking agent is divinylbenzene.

[0041] Wherein the initiator is sodium persulfate.

[0042] A preparation method of straw fiber composite adsorption material, comprising the following steps:

[0043] (1) Crush corn stalks to a particle size of 140 mesh, place them in high-temperature steam at 130°C for 80 minutes, add 2.4 times the weight of 0.7mol / L sodium hydroxide solution and soak for 15 hours;

[0044](2) Then add acrylic emulsion, crosslinking agent, initiator and dibutyltin dilaurate, stir well and react at 80°C for 0.6h, then add nano-calcium ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com