Municipal solid waste incineration plant SCR low-temperature denitration catalyst on-line regeneration system and regeneration method thereof

A technology for domestic waste incineration and low-temperature denitration, which is applied in chemical instruments and methods, separation methods, and dispersed particle separation. Reduce maintenance and replacement costs in the later period, and the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

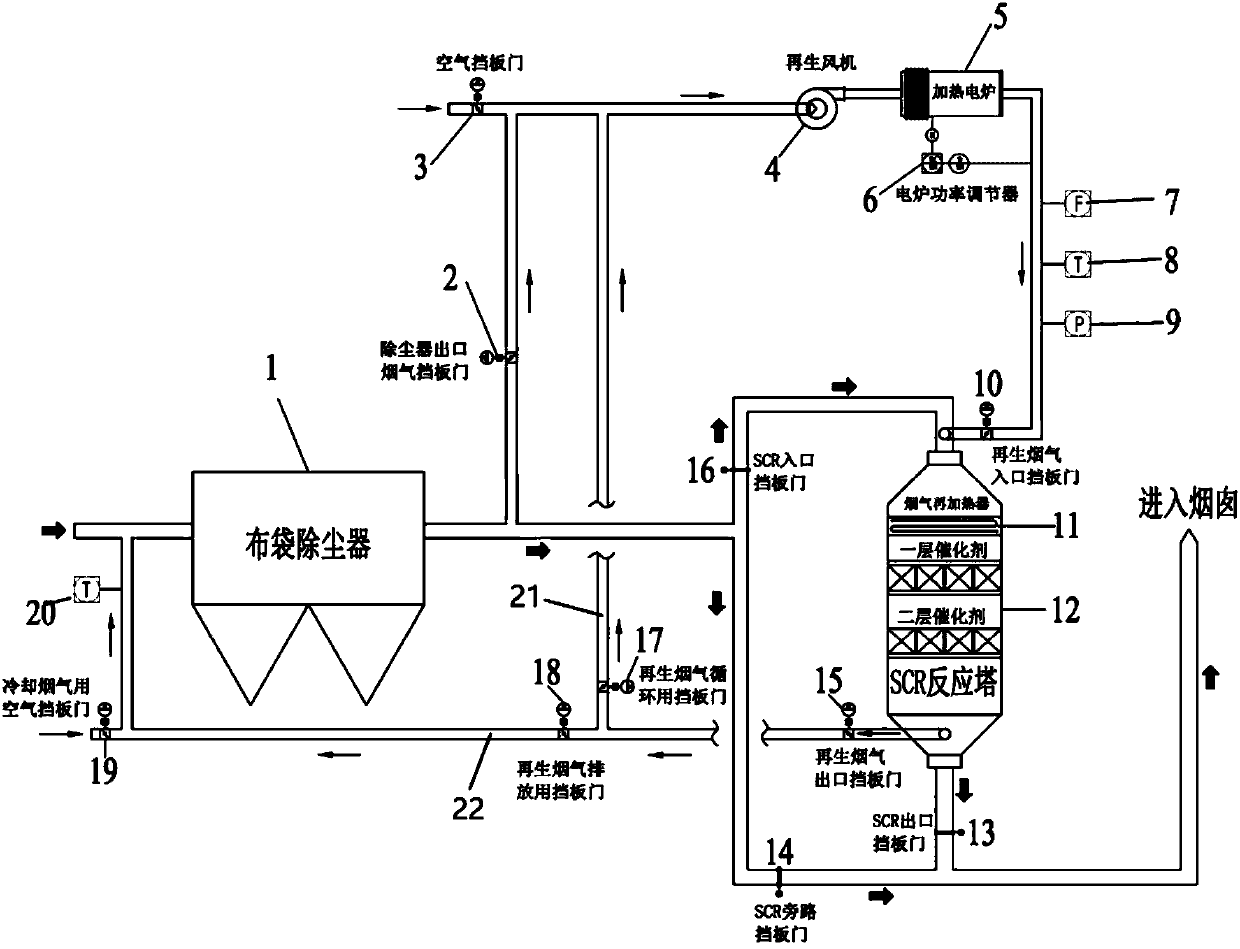

[0045] In this embodiment, the SCR catalyst regeneration of a 500-ton / day waste incineration plant is taken as an example. The total amount of catalyst in the SCR tower is about 20m 3 , the amount of flue gas to be regenerated is about 9000Nm 3 / h, the regeneration temperature is 370°C. The power of the heating electric furnace is 250kW, and the steam system of the flue gas reheater is used for auxiliary heating. The steam parameters are pressure 1.3MPa, temperature 280°C, and flow rate about 1t / h.

[0046] Close the SCR inlet baffle door 16 and the SCR outlet baffle door 13, open the SCR bypass baffle door 14, so that the flue gas at the outlet of the bag filter 1 bypasses the SCR. Open the air baffle door 3 , the regenerated flue gas inlet baffle door 10 , the regenerated flue gas outlet baffle door 15 and the regenerated flue gas circulation baffle door 17 in sequence. At the same time, the flue gas baffle door 2 at the outlet of the dust collector and the baffle door 18...

Embodiment 2

[0053]In this example, the amount of flue gas to be regenerated is about 8000Nm 3 / h, the regeneration temperature is 350°C. The power of the heating electric furnace is 300kW, and the flue gas reheater is not used.

[0054] Close the SCR inlet baffle door 16 and the SCR outlet baffle door 13, open the SCR bypass baffle door 14, so that the flue gas at the outlet of the bag filter 1 bypasses the SCR. Open the flue gas baffle door 2 at the outlet of the dust collector, the baffle door 10 for the regenerated flue gas inlet, the baffle door 15 for the regenerated flue gas outlet, and the baffle door 17 for regenerated flue gas circulation in sequence. At the same time, the air baffle door 3 and the baffle door 18 for exhausting the regenerative flue gas remain closed.

[0055] Turn on the regeneration blower 4 to extract air as flue gas for regeneration, and turn on the heating electric furnace 5, observe the flue gas flowmeter 7 at the outlet of the electric furnace 5, when th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com