La2Hf2O7 system inorganic luminous material and preparation method thereof

A luminescent material and inorganic technology, applied in luminescent materials, luminescent coatings, chemical instruments and methods, etc., can solve the problems of difficult optical anti-counterfeiting label materials and easy imitation of fluorescent characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 6

[0135] Add 1.52 mmol of lanthanum nitrate, 0.3 mmol of ytterbium nitrate, 0.18 mmol of europium nitrate, 0.002 mmol of erbium nitrate and 2 mmol of citric acid into 8 ml of ethanol, stir for 30 minutes; then add 2 mmol of hafnium acetylacetonate and Stir for 30 minutes; at 50 o The temperature of C was incubated for 2 hours to obtain the xerogel; the xerogel was ground for 30 minutes, then placed in a muffle furnace, at 700 o C was kept warm for 4 hours, and the final product was obtained after cooling with the furnace.

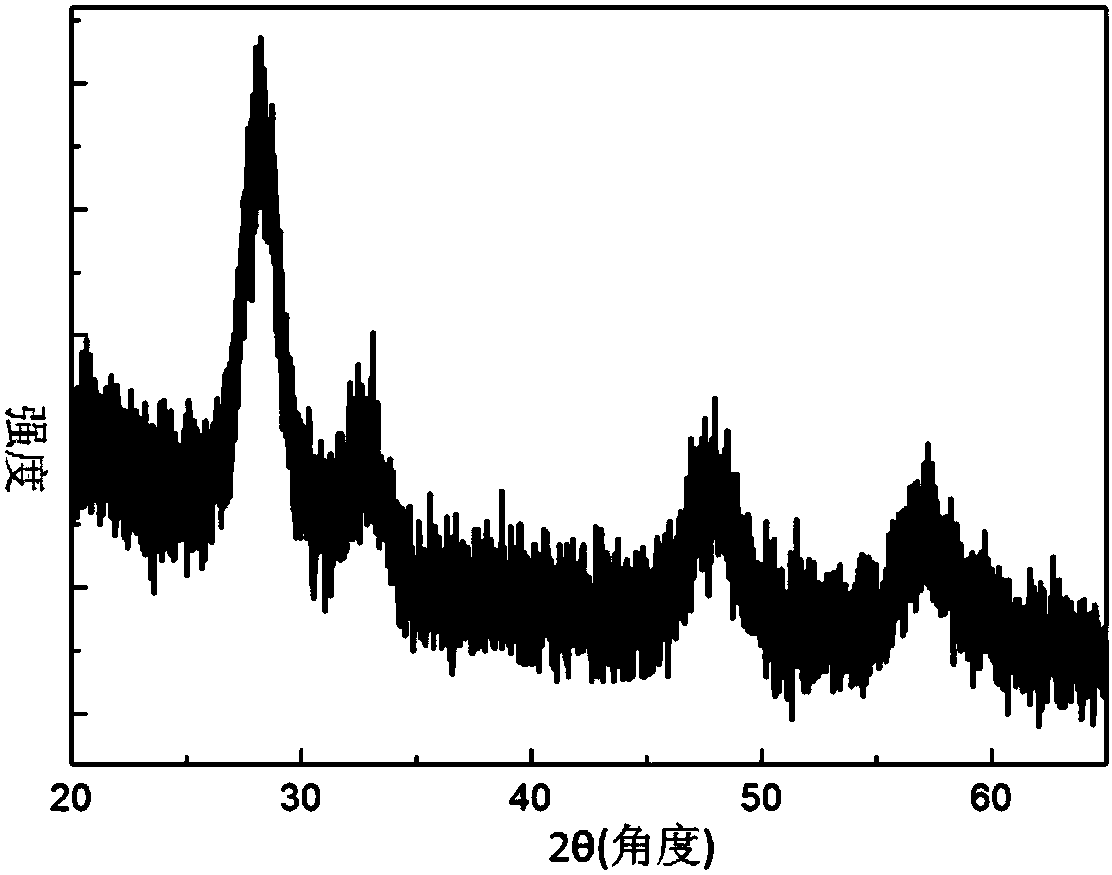

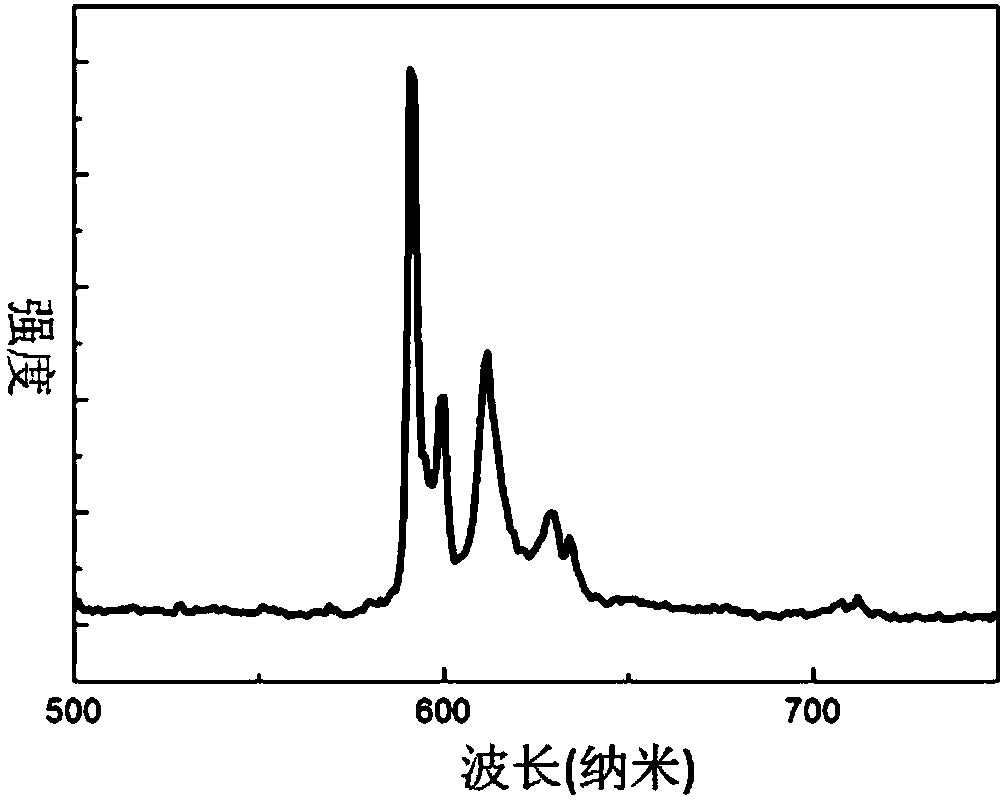

[0136] Powder X-ray diffraction analysis shows that: the obtained product is pure cubic phase La 2 f 2 o 7 ( figure 1 ). Under 980nm laser irradiation, Yb / Er / Eu: La 2 f 2 o 7 Can get Er 3+ Ions emit bright green light with faint Eu in the spectrum 3+ Luminescence band ( figure 2 ). at 298nm ( image 3 ), 365nm ( Figure 4 ) with 415nm ( Figure 5 ) under xenon lamp excitation conditions, Eu 3+ Bright red light is emitted.

Embodiment 2

[0138] Add 1.68 mmol of lanthanum nitrate, 0.2 mmol of ytterbium nitrate, 0.12 mmol of europium nitrate, 0.005 mmol of erbium nitrate and 2 mmol of citric acid into 8 ml of ethanol, stir for 30 minutes; then add 2 mmol of hafnium acetylacetonate and Stir for 30 minutes; heat at 50°C for 2 hours to obtain dry gel; grind the dry gel for 30 minutes, then put it in a muffle furnace, keep it at 700°C for 4 hours, and cool down with the furnace to obtain the final product.

Embodiment 3

[0140] Add 1.42 mmol of lanthanum nitrate, 0.5 mmol of ytterbium nitrate, 0.08 mmol of europium nitrate, 0.001 mmol of erbium nitrate and 2 mmol of citric acid into 8 ml of ethanol, stir for 30 minutes; then add 2 mmol of hafnium acetylacetonate and Stir for 30 minutes; heat at 50°C for 2 hours to obtain dry gel; grind the dry gel for 30 minutes, then put it in a muffle furnace, keep it at 700°C for 4 hours, and cool down with the furnace to obtain the final product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com