Transmission line tower fluorocarbon coating having resistance to ultraviolet rays and ageing, and preparation method thereof

A transmission line, anti-ultraviolet technology, applied in the direction of coating, etc., can solve the problems of unresolved aging resistance of composite materials, affecting the safety of towers, resin aging and crushing, etc., to achieve excellent anti-ultraviolet and anti-aging performance, simple construction, and curing fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

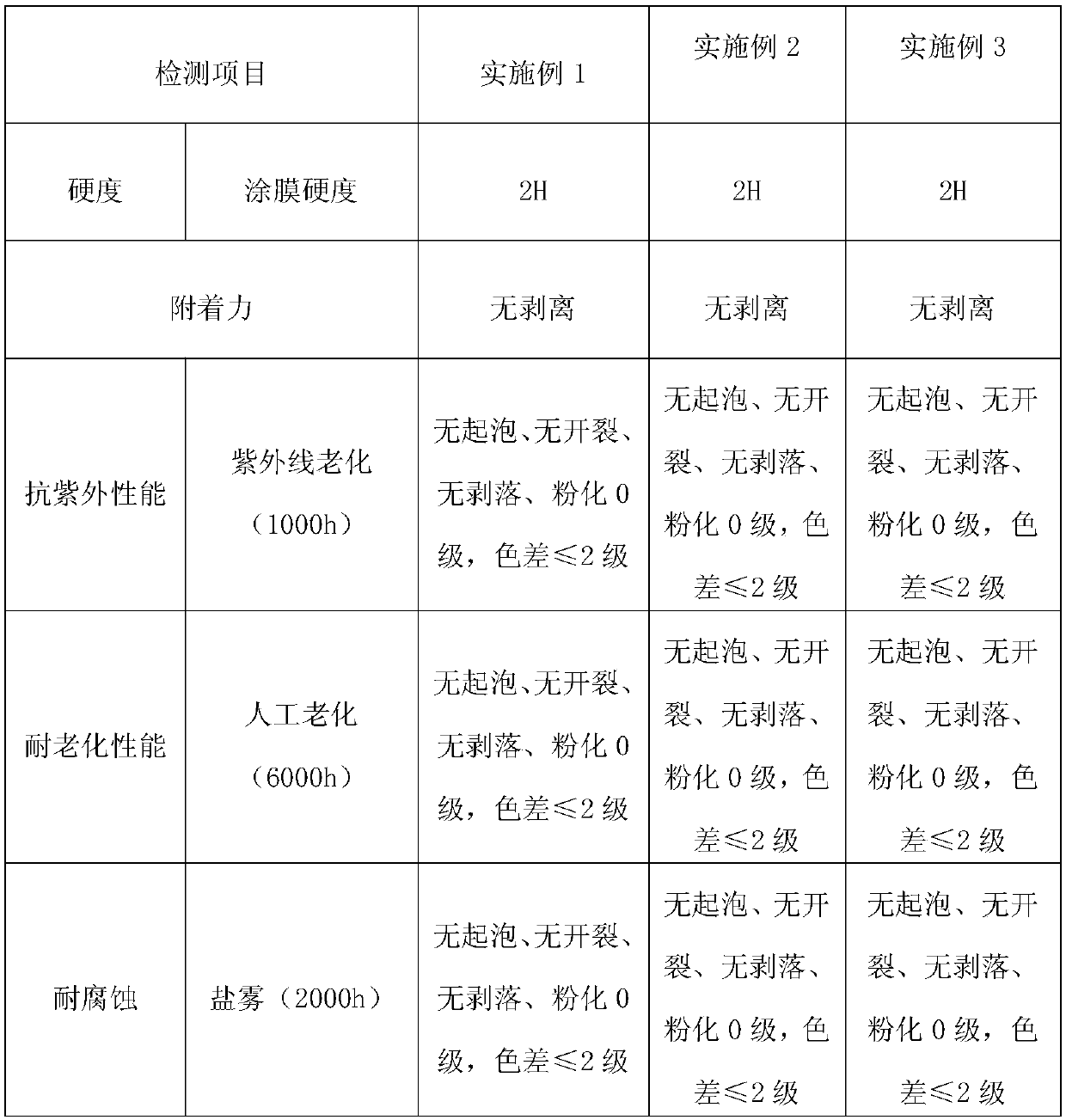

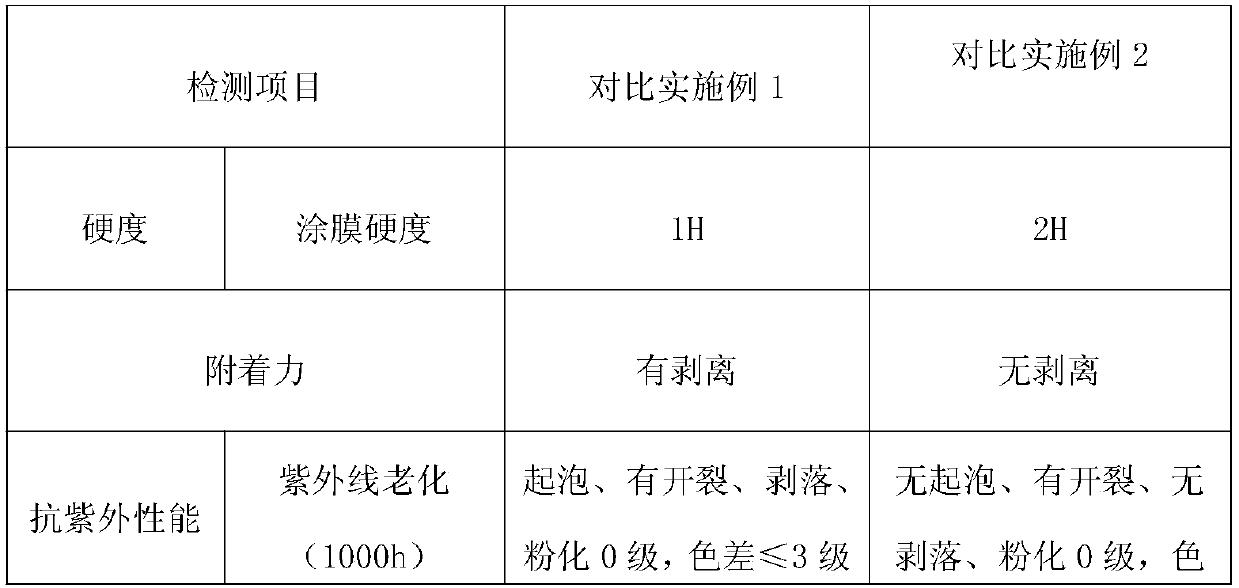

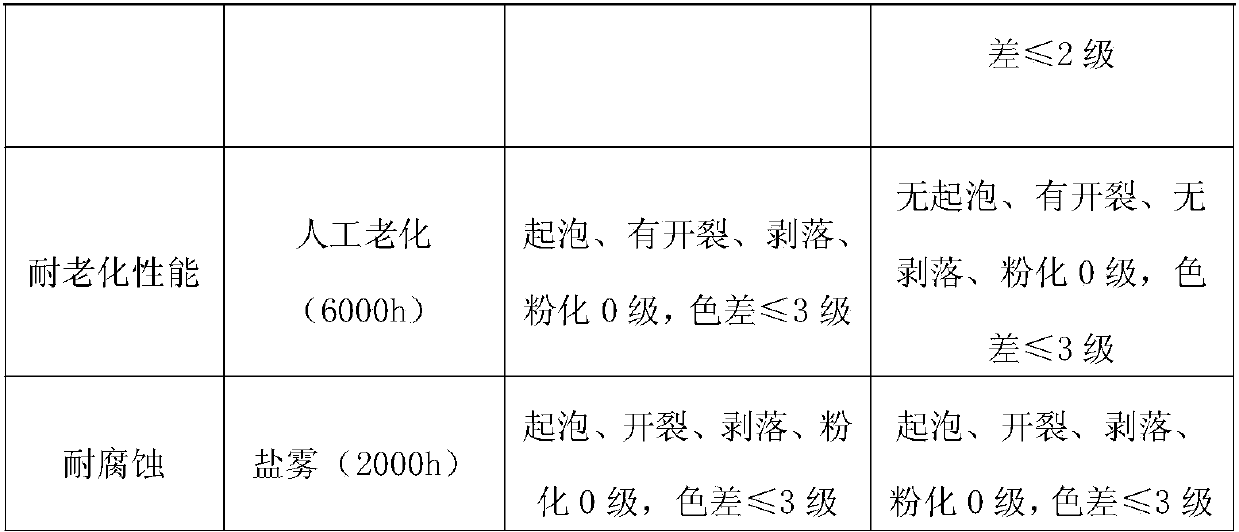

Examples

Embodiment 1

[0022] 1. A transmission line tower fluorocarbon coating with anti-ultraviolet and anti-aging, which is composed of the following raw materials in parts by weight: 12 parts of fluorocarbon resin, 1 part of color filler, 5 parts of diluting solvent and 1 part of curing agent.

[0023] The color filler is an inorganic pigment; the diluting solvent is acetone; the curing agent is an acid anhydride curing agent specially used for fluorocarbon resins.

[0024] 2. The preparation method of the anti-ultraviolet and anti-aging transmission line tower fluorocarbon coating of the present invention comprises the following steps:

[0025] a. First, polish the shaft surface of the transmission line tower to remove surface dust, water and oil;

[0026] b. Mix and stir 12 parts of the fluorocarbon resin, 1 part of color filler, 5 parts of diluting solvent and 1 part of curing agent evenly, and after curing for 10 minutes, spray at 20°C-40°C and relative humidity ≤75%. the shaft surface of t...

Embodiment 2

[0033] 1. A transmission line tower fluorocarbon coating with anti-ultraviolet and anti-aging, which is composed of the following raw materials in parts by weight: 10 parts of fluorocarbon resin, 2 parts of color filler, 4 parts of diluting solvent and 2 parts of curing agent.

[0034] The color filler is an inorganic pigment; the diluting solvent is acetone; and the curing agent is a special amine curing agent for fluorocarbon resin.

[0035] 2. The preparation method of the anti-ultraviolet and anti-aging transmission line tower fluorocarbon coating of the present invention comprises the following steps:

[0036] a. First, polish the shaft surface of the transmission line tower to remove surface dust, water and oil;

[0037] b. Mix and stir 10 parts of the fluorocarbon resin, 2 parts of color filler, 4 parts of diluting solvent and 2 parts of curing agent evenly, and after curing for 10 minutes, spray at 30°C-40°C and relative humidity ≤75%. the shaft surface of the transmi...

Embodiment 3

[0042] 1. A transmission line tower fluorocarbon coating with anti-ultraviolet and anti-aging, which is composed of the following raw materials in parts by weight: 11 parts of fluorocarbon resin, 1.5 parts of color filler, 4.5 parts of diluting solvent and 1.5 parts of curing agent.

[0043] The color filler is an organic pigment; the diluting solvent is acetone; the curing agent is a special amine curing agent for fluorocarbon resin.

[0044] 2. The preparation method of the anti-ultraviolet and anti-aging transmission line tower fluorocarbon coating of the present invention comprises the following steps:

[0045] a. First, polish the shaft surface of the transmission line tower to remove surface dust, water and oil;

[0046] b. Mix and stir 11 parts of the fluorocarbon resin, 1.5 parts of color filler, 4.5 parts of diluting solvent and 1.5 parts of curing agent evenly, and after curing for 10 minutes, spray at 20°C-30°C and relative humidity ≤75%. the shaft surface of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com