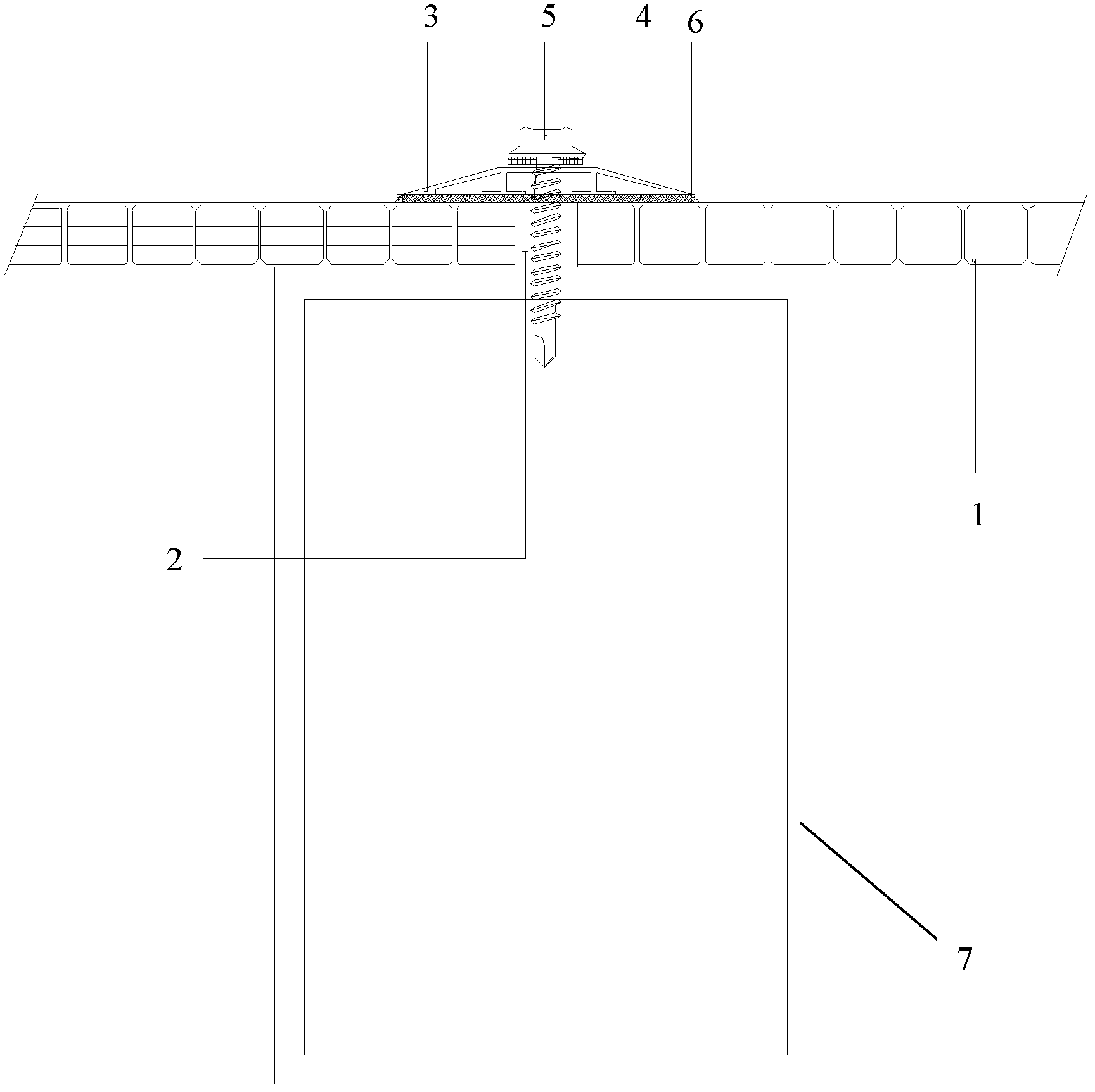

Greenhouse with novel polycarbonate sheet roofing structure

A solar panel, U-shaped technology, applied in the field of greenhouses, can solve the problems of loose joints and complicated installation methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

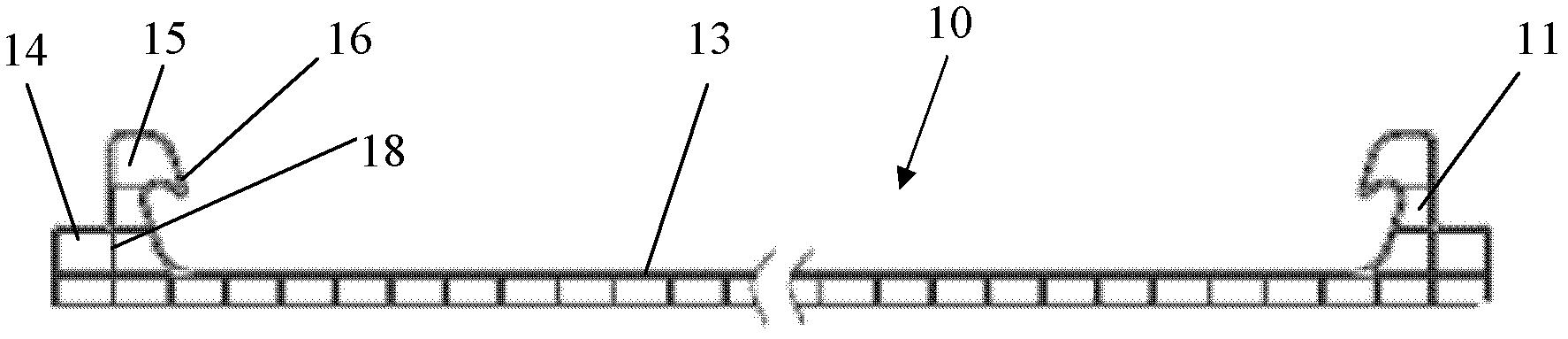

[0156] Sun panel buckle

[0157] The solar panel buckle in this embodiment includes a buckle body and a buckle part, wherein two sides of the buckle body extend downward to form two buckle parts.

[0158] The buckle part has 1-2 tooth tips, and the tooth tips face to the inside of the buckle body.

[0159] The sun panel buckle is a solid structure made of polycarbonate, white and opaque, with a width of 30-60mm, a height of 15-40mm and a length of 10-60m.

Embodiment 2

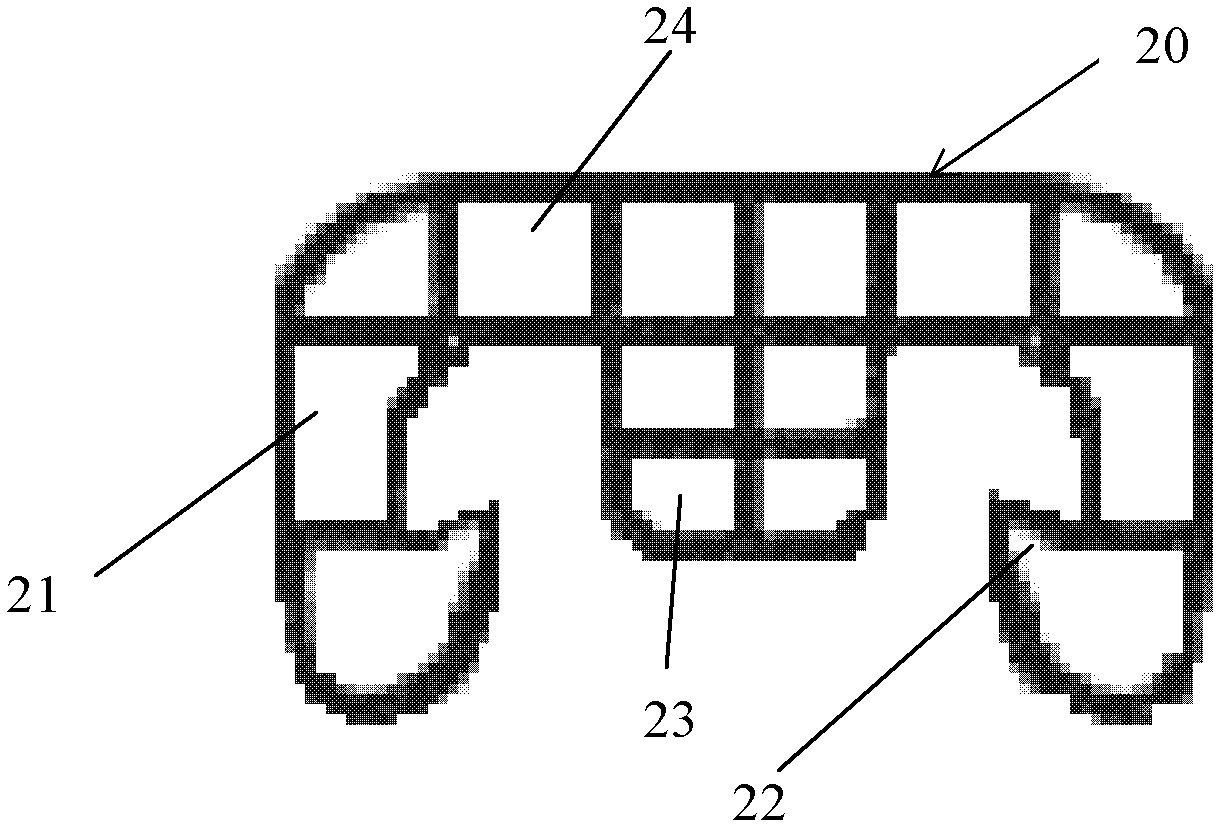

[0161] Sun panel buckle

[0162] The solar panel buckle in this embodiment includes a buckle body and a buckle part, wherein two sides of the buckle body extend downward to form two buckle parts.

[0163] The buckle part has 1-3 tooth tips, and the tooth tips face the inside of the buckle body.

[0164] The composition of the sun panel buckle is 95-98wt% polycarbonate, and the balance is 2-5wt% polycarbonate anti-UV material. UV protective layer.

[0165] The sun board buckle is a one-layer hollow structure with 3 to 20 through holes running through the buckle body and the buckle part.

[0166] The sun panel buckle has a width of 30-60mm, a height of 15-40mm and a length of 1-40m.

[0167] The sun board buckle is transparent, and the light transmittance is greater than 90%.

Embodiment 3

[0169] Sun panel buckle

[0170] The structural composition of the sun board buckle of the present embodiment is basically the same as that of the sun board buckle of embodiment 2, the difference is only in:

[0171] The inner side of the middle part of the buckle body of the sun panel buckle extends downward to form a buckle part.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com