Tread rubber filled with environment-friendly white carbon black and butadiene styrene rubber and preparation method of tread rubber

A technology of silica butyl and rubber tread, which is applied in the direction of special tires, tire parts, rolling resistance optimization, etc., can solve the problems of easy agglomeration, bluing, uneven dispersion of silica, etc., to improve wear resistance, High purity, reducing the effect of catalytic oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A preparation method for filling environment-friendly white carbon black styrene-butadiene rubber tread rubber, comprising the steps: wherein each component is by weight percentage

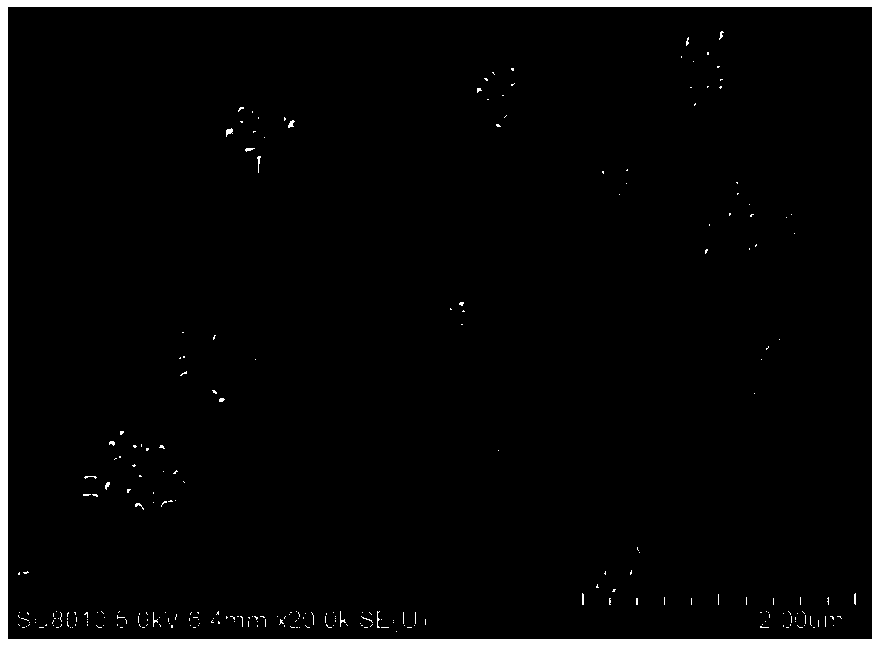

[0028] The modification steps of rice husk source silica are as follows: the mixture of 2.4 parts of silane coupling agent Si-69 and 30 parts of rice husk source silica is placed in a high-speed disperser, and is dispersed and rotated at a high speed of 1300rpm for 1 hour; The dispersed mixture was placed in an oven for 2.5 hours, and the temperature of the oven was set at 140°C;

[0029] (1) One-stage master batching: 30 parts of natural rubber, 70 parts of styrene-butadiene rubber, 20 parts of carbon black, 30 parts of white carbon black, 3 parts of aromatic oil, 2 parts of stearic acid, 4 parts of zinc oxide, 2 parts of viscosity increaser Resin, 2 parts of anti-crack resin, put into the internal mixer for mixing at the same time, the effective filling coefficient of the rubber material ...

Embodiment 2

[0033] A preparation method for filling environment-friendly white carbon black styrene-butadiene rubber tread rubber, comprising the steps: wherein each component is by weight percentage

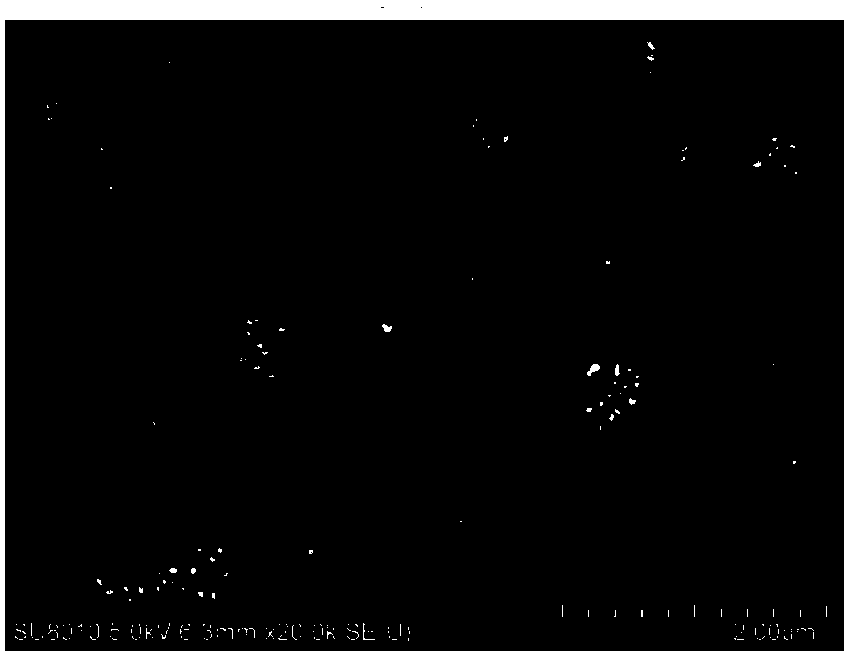

[0034]The specific modification steps of rice husk source silica are as follows: 1.4 parts of silane coupling agent Si-69 and 35 parts of rice husk source silica mixture are placed in a high-speed disperser, and disperse and rotate at a high speed of 1500 rpm for 1.5 hours; The dispersed mixture was placed in an oven for 2.5 hours, and the temperature of the oven was set at 140°C;

[0035] (1) One-stage master batching: 40 parts of natural rubber, 60 parts of styrene-butadiene rubber, 25 parts of carbon black, 25 parts of white carbon black, 3 parts of aromatic oil, 1.5 parts of stearic acid, 3 parts of zinc oxide, and 1.5 parts of thickening Resin, 1.5 parts of anti-crack resin, put into the internal mixer for mixing at the same time, the effective filling coefficient of the rubber materia...

Embodiment 3

[0039] A preparation method for filling environment-friendly white carbon black styrene-butadiene rubber tread rubber, comprising the steps: wherein each component is by weight percentage

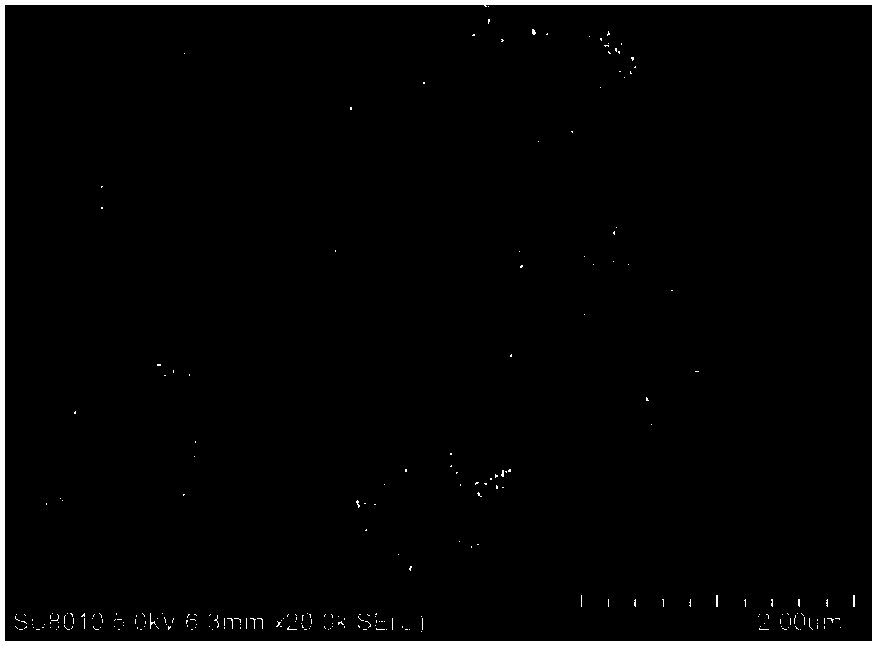

[0040] Rice husk source silica was added directly into the internal mixer without Si-69 modification.

[0041] (1) One-stage master batching: 25 parts of natural rubber, 75 parts of styrene-butadiene rubber, 30 parts of carbon black, 5 parts of white carbon black, 4 parts of aromatic oil, 2.5 parts of stearic acid, 4 parts of zinc oxide, and 2 parts of viscosity increaser Resin, 2 parts of anti-crack resin, put into the internal mixer for mixing at the same time, the effective filling factor of the rubber material is 0.75, the pressure of the top bolt is 5.5Bar, the rotor speed is 50 rpm, and the water temperature of the cooling circuit in the mixing chamber is 40°C, the temperature of the rotor is 35°C, the mixing time is 140 seconds, after the mixing is completed, the glue is discharged. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wear volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com