A kind of asphalt sacrificial layer and its preparation method and application

A technology of asphalt and coarse aggregate, which is applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problem of steel slag not being able to be effectively used, so as to improve competitive advantage, enhance road performance, and enhance wear resistance The effect of sex and intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

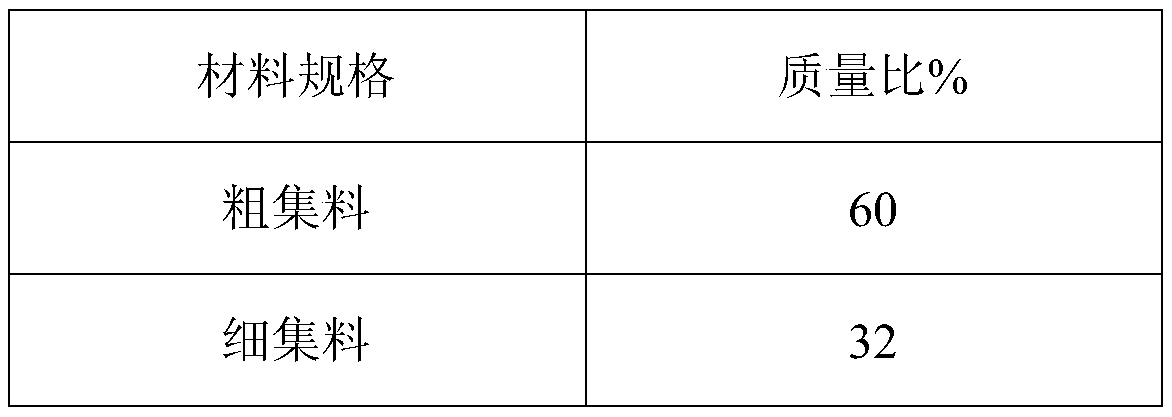

[0039] The following formula is an ordinary SMA-10 ultra-thin wear layer. Both the coarse aggregate and the fine aggregate are made of diabase, the mineral powder is made of limestone powder, and the asphalt is made of SBS modified asphalt. The oil-stone ratio in this example refers to the ratio of asphalt to The ratio of the total mass of coarse aggregate to fine aggregate.

[0040] Material specification Mass ratio% Coarse aggregate (10-5mm) 60 Fine aggregate (0-3mm, 3-5mm) 27 limestone powder 13 Oil stone ratio% 6.0

Embodiment 2

[0042]The following formula is the asphalt loss layer in this application scheme. The coarse aggregate is made of steel slag, the fine aggregate and steel slag powder are made of steel slag, and the asphalt is made of SBS modified asphalt.

[0043] Material specification Mass ratio% Coarse aggregate (10-5mm) 65 fine aggregate 24 steel slag powder 11 Oil stone ratio% 6.2

Embodiment 3

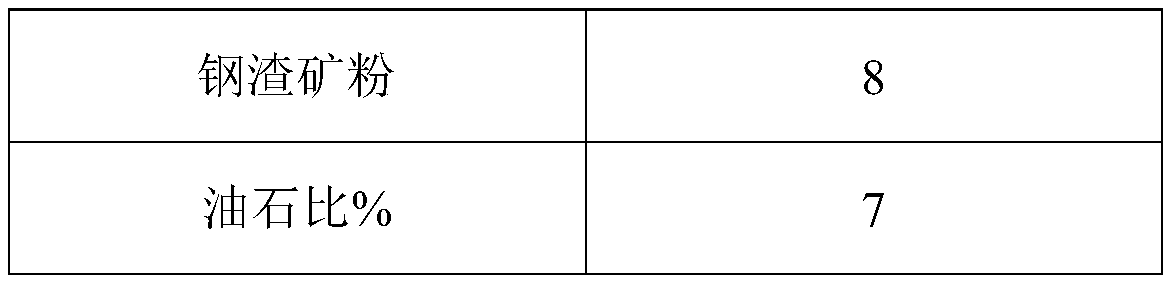

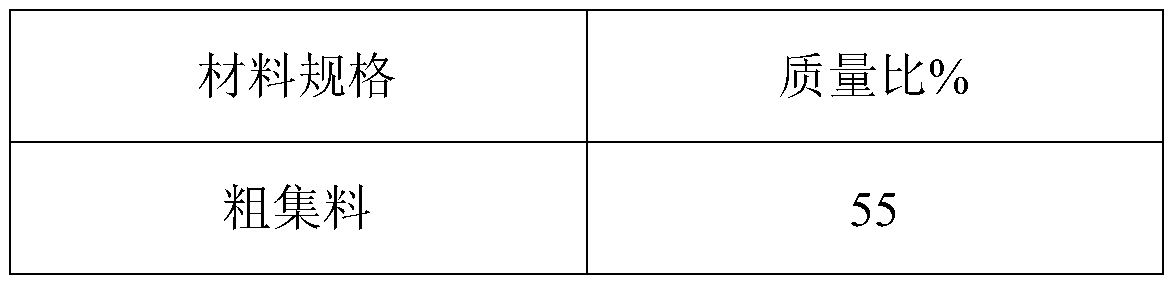

[0045] The following formula is the asphalt loss layer in this application scheme. The coarse aggregate is made of steel slag, the fine aggregate and steel slag powder are made of steel slag, and the asphalt is made of SBS modified asphalt.

[0046]

[0047]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com