Working method of double-linkage conveyor discharge valve

A working method and technology of unloading valve, applied in the direction of conveyor objects, transportation and packaging, loading/unloading, etc., can solve problems such as affecting discharge, interfering materials, accumulation, etc., to optimize smoothness, clear material condensation or blockage or stacking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

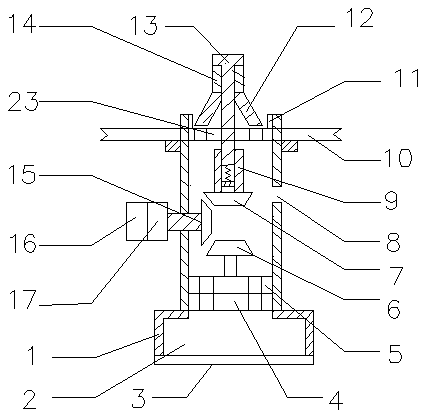

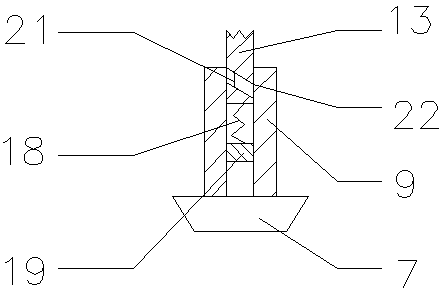

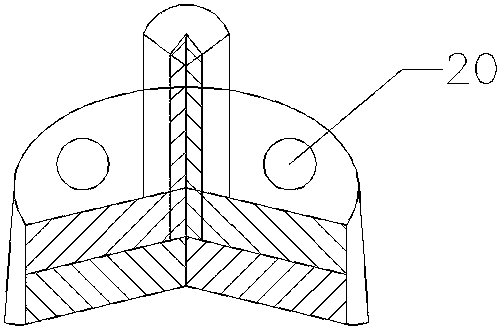

[0022] As shown in the figure: a working method of the unloading valve of a double-linkage conveyor. The unloading valve includes a valve body, a weighing chamber, a weighing plate, a static valve disc, a moving valve disc, a first angular gear, a Angle gear, temperature control port, rod sleeve, limiter, closure, valve stem, pivot rod, third angle gear, motor, reduction mechanism, spring, support disc, through hole, bump, spiral groove, upper valve disc The cross-section of the valve body is inverted T-shaped, the upper part is cylindrical, and the diameter of the lower part is larger than that of the upper part. The lower part of the valve body extends integrally to form a weighing chamber. A pivot is set in the middle of the circle, and the weighing plate can rotate along the pivot; the upper end of the valve body extends inward to form a ring-shaped limiter, which encloses an opening, and the lower surface of the ring-shaped limiter is provided with an upper valve disc, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com