Nanosheet hydroxyapatite/gel composite film with brick-mud structure and preparation method thereof

A technology of hydroxyapatite and nano flakes, which is applied in the field of preparation of nano biomedical materials, can solve the problems of difficult preparation of flake HAp, not easy to disperse, difficult to form composite materials, etc., to achieve good biological activity and biophase Capacitive, superior mechanical properties, low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1, preparation has the nanosheet hydroxyapatite / gelatin composite film of brick-mud structure, and the steps are as follows:

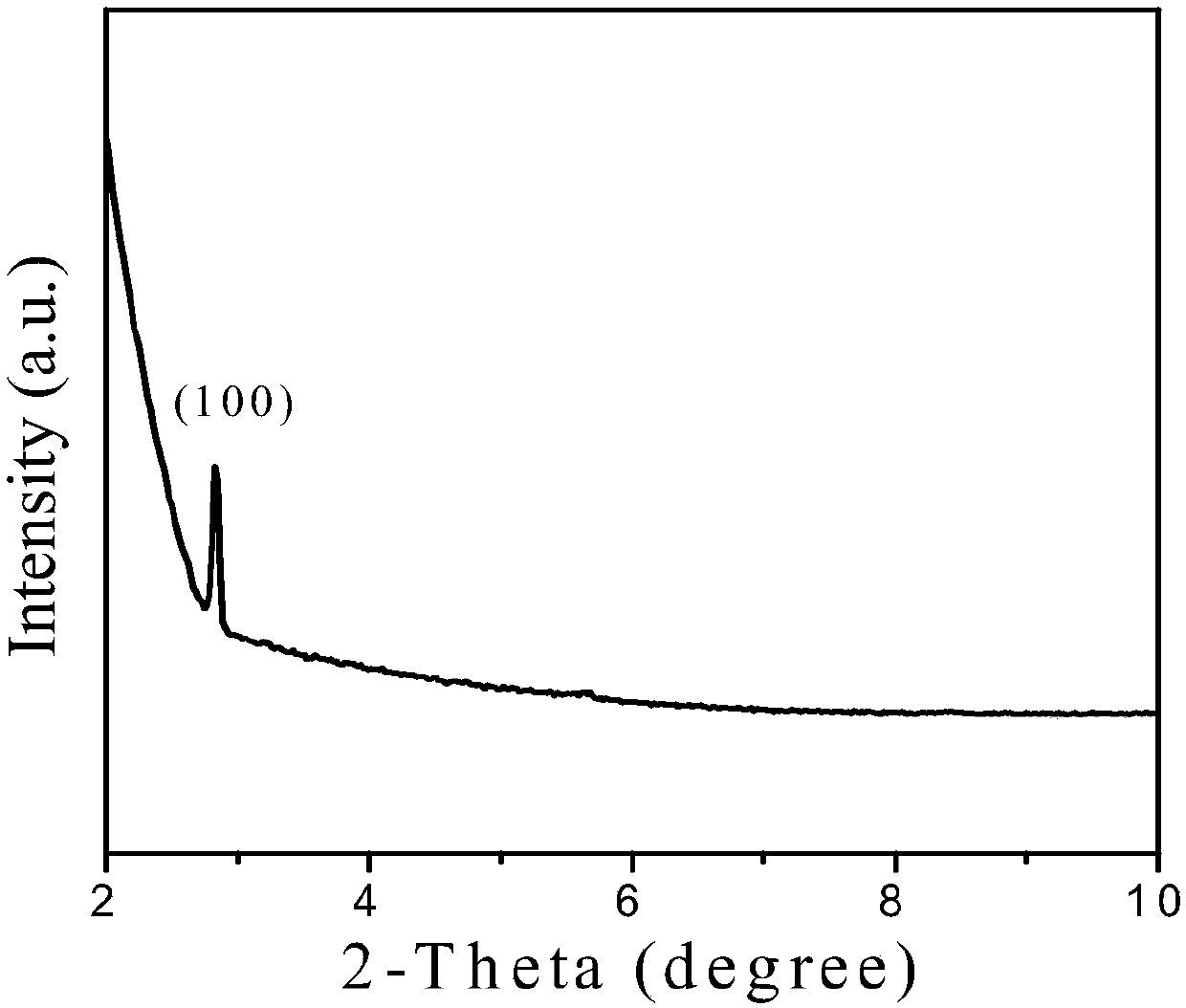

[0018] Step 1) 15ml of deionized water and 30ml of absolute ethanol were mixed, 0.1g of template agent SDS and 11.80g of Ca(NO 3 ) 2 4H 2 O and 3.96g of (NH 4 ) 2 HPO 4 Dissolve in the above mixed solvent, raise the temperature to 83°C for reflux reaction for 14h, pour the reactant into a beaker, seal it and settle at room temperature for 12 days to obtain nano-layered hydroxyapatite (L-HAp) with a double-layer ordered structure , its small-angle X-ray diffraction pattern is as figure 1 shown.

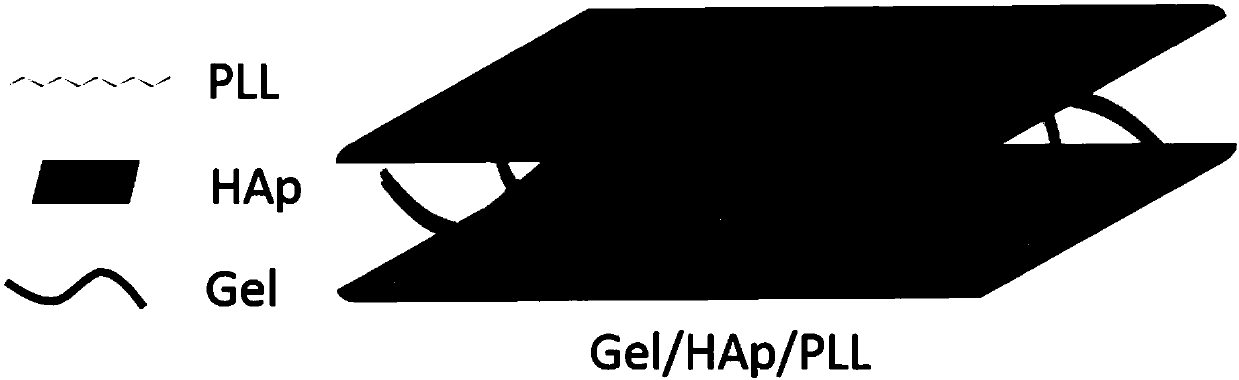

[0019] Step 2) Prepare a GelPBS solution with a concentration of 1% (pH=7.4), heat up to 80° C., add the prepared double-layer ordered structure L-HAp into the GelPBS solution, wherein the double-layer ordered structure L-HAp and The mass ratio of Gel is 25:75, and the nano-layered hydroxyapatite L-HAp / Gel with a double-layer structure ...

Embodiment 2

[0022] Embodiment 2, preparation has the nano-flaky hydroxyapatite / gelatin composite film of brick-mud structure, and the steps are as follows:

[0023] Step 1) is basically the same as that in Example 1, except that the addition amount of template agent SDS is changed from 0.1 g to 0.25 g to obtain L-HAp with double-layer ordered structure.

[0024] Step 2) is basically the same as that of Example 1, except that the concentration of the PBS solution of Gel is changed from 1% to 6%, the temperature of the heating is changed from 80°C to 60°C, and the prepared double-layer ordered structure L -HAp was added to the PBS solution of Gel to obtain L-HAp / Gel with a mass ratio of L-HAp to Gel of 35:65.

[0025] Step 3) is basically the same as in Example 1, except that the concentration of the PLL aqueous solution is changed from 0.1% to 0.5%, the amount of L-HAp / Gel added is changed from 0.5 mg to 1 mg, and finally the surface modified PLL is obtained and the interlayer L-HAp inter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com