Method for measuring physical property of magneto-optical dielectric film under low-temperature and high-pressure condition

A magneto-optical medium, low temperature and high pressure technology, applied in the measurement of magnetic variables, the size/direction of the magnetic field, measuring devices, etc., can solve problems such as difficulties, opacity, and magnetic properties of tungsten carbides to prevent liquid pressure media Leakage, reduced probability of chipping, high conductivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

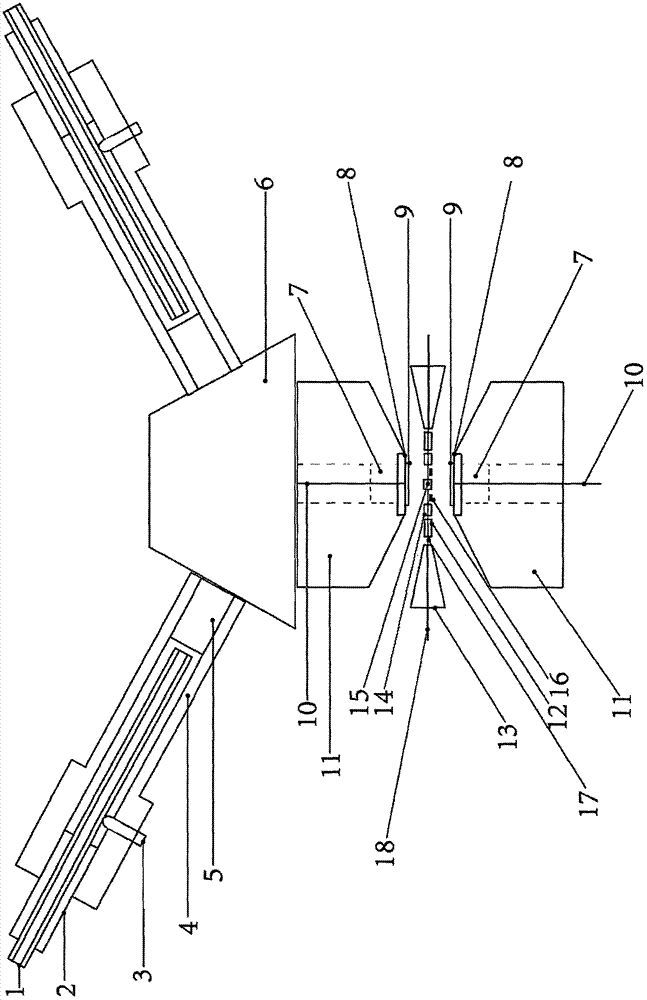

[0018] Such as figure 1It is a schematic diagram of the structure of the present invention, mainly including optical fiber (1), displacement tube (2), screw (3), sleeve (4), gradient index lens (5), silicon carbide support table (6), epoxy resin and Diamond particle mixture (7), PTFE film (8), conductive glass electrode plate (9), current lead (10), tungsten carbide anvil (11), stainless steel ring (12), aluminum gasket (13), Teflon ring (14), sample (15), support particles (16), gold wire (17), copper wire (18), magnet, laser, polarizer, photodetector, magnet for generating a magnetic field at the sample location, The tungsten carbide anvil (11) includes an upper anvil and a lower anvil, and the center of the axis has a through hole, and the epoxy resin and the diamond particle mixture (7) are filled in the holes, and are all covered in turn. The PTFE membrane (8) and the conductive glass electrode plate (9), the liquid pressure medium will not leak under high pressure, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com