Preparation method of compound fruit extract

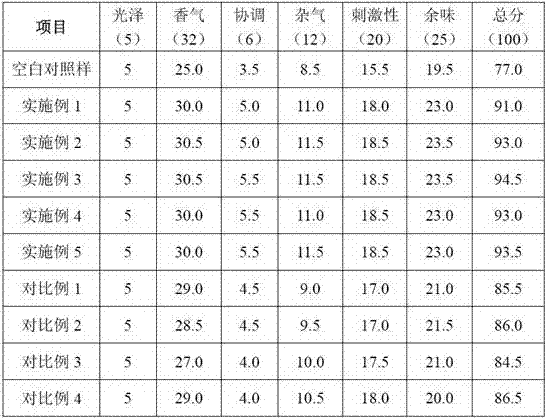

A technology for extracts and fruits, which is applied in the field of preparation of compound fruit extracts, which can solve problems such as insufficient aftertaste, insufficient tobacco flavor of cigarettes, and high irritation, and achieve improved cigarette smoking, rich and delicate aroma of extracts, and aroma of extracts More effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A preparation method of compound fruit extract, the preparation steps comprising:

[0025] (1) Fresh mulberry and indigo fruit are chopped and mixed according to the mass ratio of 1:1. The mixture is soaked in a gallic acid aqueous solution with a solute concentration of 10g / L and heated and boiled for pretreatment. The added weight of the gallic acid aqueous solution is mulberry and indigo. 5 times of the total weight of the chopped fruit mixture, the boiling time is 5min, and the solid-liquid separation after pretreatment is used to obtain the treated liquid and solid phase filtrate;

[0026] (2) Soak the solid-phase filtrate in a compound enzyme extract of cellulase and pectinase and extract in a constant temperature water bath at 45 to 50°C for 2 hours, wherein the mass ratio of each component in the compound enzyme extract is cellulase: pectinase Glue enzyme: sterile water=7:7:1000, the material / liquid mass ratio of solid-phase filtrate and complex enzyme extract i...

Embodiment 2

[0031] A preparation method of compound fruit extract, the preparation steps comprising:

[0032] (1) Fresh mulberry and indigo fruit are chopped and mixed in a mass ratio of 1:3, the mixture is soaked in a gallic acid aqueous solution with a solute concentration of 20g / L, heated and boiled for pretreatment, and the added weight of the gallic acid aqueous solution is mulberry and indigo. 5 times of the total weight of the chopped fruit mixture, the boiling time is 5min, and the solid-liquid separation after pretreatment is used to obtain the treated liquid and solid phase filtrate;

[0033] (2) Soak the solid-phase filtrate in a compound enzyme extract of cellulase and pectinase and extract in a constant temperature water bath at 45 to 50°C for 2 hours, wherein the mass ratio of each component in the compound enzyme extract is cellulase: pectinase Glue enzyme: sterile water=7:7:1000, the material / liquid mass ratio of solid-phase filtrate and complex enzyme extract is 1:3, filt...

Embodiment 3

[0038] A preparation method of compound fruit extract, the preparation steps comprising:

[0039] (1) Fresh mulberry and indigo fruit are chopped and mixed in a mass ratio of 1:4, the mixture is soaked in a gallic acid aqueous solution with a solute concentration of 40g / L, heated and boiled for pretreatment, and the added weight of the gallic acid aqueous solution is mulberry and indigo. 5 times the total weight of the chopped fruit mixture, the boiling time is 10min, and the solid-liquid separation after pretreatment is used to obtain the treated liquid and solid phase filtrate;

[0040] (2) Soak the solid-phase filtrate in a compound enzyme extract of cellulase and pectinase and extract in a constant temperature water bath at 45-50°C for 2.5 hours, wherein the mass ratio of each component in the compound enzyme extract to cellulase: Pectinase: sterile water = 8:10:1000, the material / liquid mass ratio of the solid-phase filtrate and the compound enzyme extract is 1:4, filter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com