A rosemary cigarette spice and a preparing method and applications thereof

A technology of rosemary and spices, applied in the direction of essential oils/spices, applications, tobacco, etc., can solve the problems of uncoordinated aroma style, limited use, and insufficient fragrance, and achieve obvious and good compatibility of herbal aroma and fragrance , aroma coordination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A kind of rosemary flavoring for tobacco that embodiment one provides, its preparation method is specifically as follows:

[0030] (1) Wash the leaves of fresh rosemary and drain the water. The pre-freezing temperature is -15~-35°C, the pre-freezing time is 4-6h, the freeze-drying pressure is 15-25Pa, and the freeze-drying time is 18~ After 24 hours of vacuum freeze-drying, dry leaves are made, then put into a pressure container, and CO2 is injected into the container 2 Gas, the pressure is increased to 60MPa, and pressurized to maintain CO 2 The liquid state of 10min, release pressure rapidly to normal pressure state, obtain the rosemary raw material after puffing;

[0031] (2) Pack the raw material expanded in step (1) into a supercritical extraction device, adjust the extraction pressure to 35Mpa, and the extraction temperature is 35°C, CO 2 The flow rate is 25kg / h, and the rosemary extract is obtained after 2 hours of extraction;

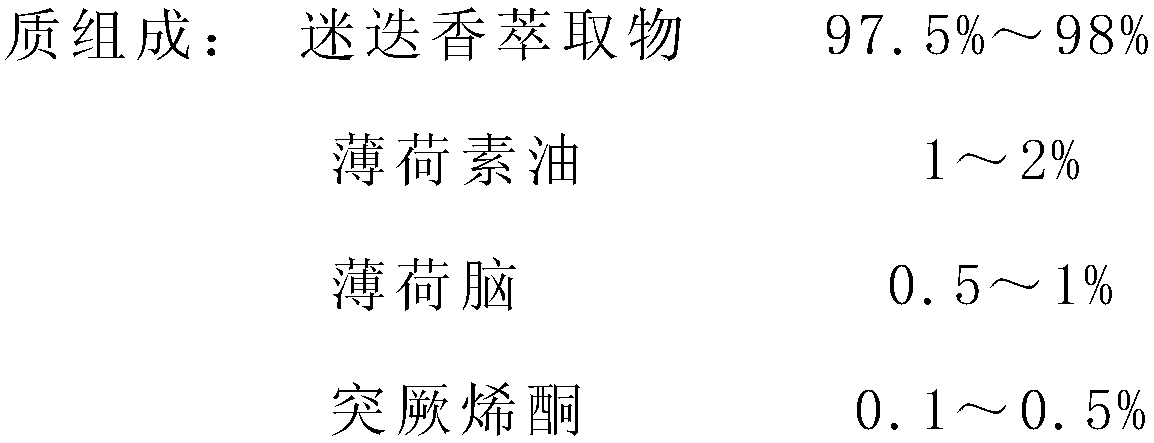

[0032] (3) Add 1.5% peppermint ...

Embodiment 2

[0033] A kind of rosemary flavoring for tobacco that embodiment two provides, its preparation method is specifically as follows:

[0034] (1) Wash the leaves of fresh rosemary and drain the water. The pre-freezing temperature is -15~-35°C, the pre-freezing time is 4-6h, the freeze-drying pressure is 15-25Pa, and the freeze-drying time is 18~ After 24 hours of vacuum freeze-drying, dry leaves are made, then put into a pressure container, and CO2 is injected into the container 2Gas, the pressure is increased to 50MPa, and pressurized to maintain CO 2 The liquid state of 15min, release pressure rapidly to normal pressure state, obtain the rosemary raw material after puffing;

[0035] (2) Pack the raw material expanded in step (1) into a supercritical extraction device, adjust the extraction pressure to be 25Mpa, and the extraction temperature is 45°C, CO 2 The flow rate is 40kg / h, and the rosemary extract is obtained after extraction for 1.5h;

[0036] (3) Add 1% peppermint oi...

Embodiment 3

[0037] A kind of rosemary flavoring for tobacco that embodiment three provides, its preparation method is specifically as follows:

[0038] (1) Wash the leaves of fresh rosemary and drain the water. The pre-freezing temperature is -15~-35°C, the pre-freezing time is 4-6h, the freeze-drying pressure is 15-25Pa, and the freeze-drying time is 18~ Under the condition of 24h, dry leaves are made after vacuum freeze-drying, then put into a pressure container, and CO2 is injected into the container 2 Gas, the pressure is increased to 45MPa, and pressurized to maintain CO 2 The liquid state of 20min, release pressure rapidly to normal pressure state, obtain the rosemary raw material after puffing.

[0039] (2) Pack the raw material expanded in step (1) into a supercritical extraction device, adjust the extraction pressure to be 30Mpa, and the extraction temperature is 40°C, CO 2 The flow rate is 45kg / h, and the rosemary extract is obtained after 1.5h of extraction.

[0040] (3) Add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com