A fermented carbonized walnut shell particle and its preparation method and application

A technology for walnut shells and granules, which is applied to the field of fermented carbonized walnut shell granules and their preparation, can solve the problems of insignificant adsorption effect of harmful substances in smoke, inability to give fragrance to cigarettes, poor coordination of cigarette aromas, and the like, and achieve good commercial application. value, increase the utilization rate, and facilitate the effect of industrialized production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

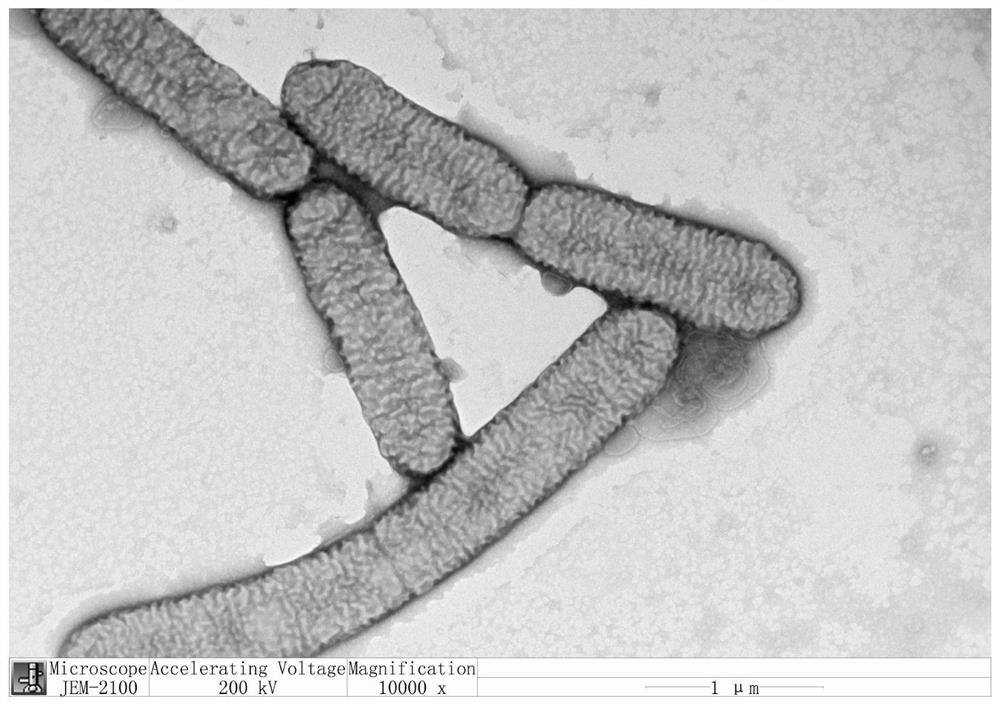

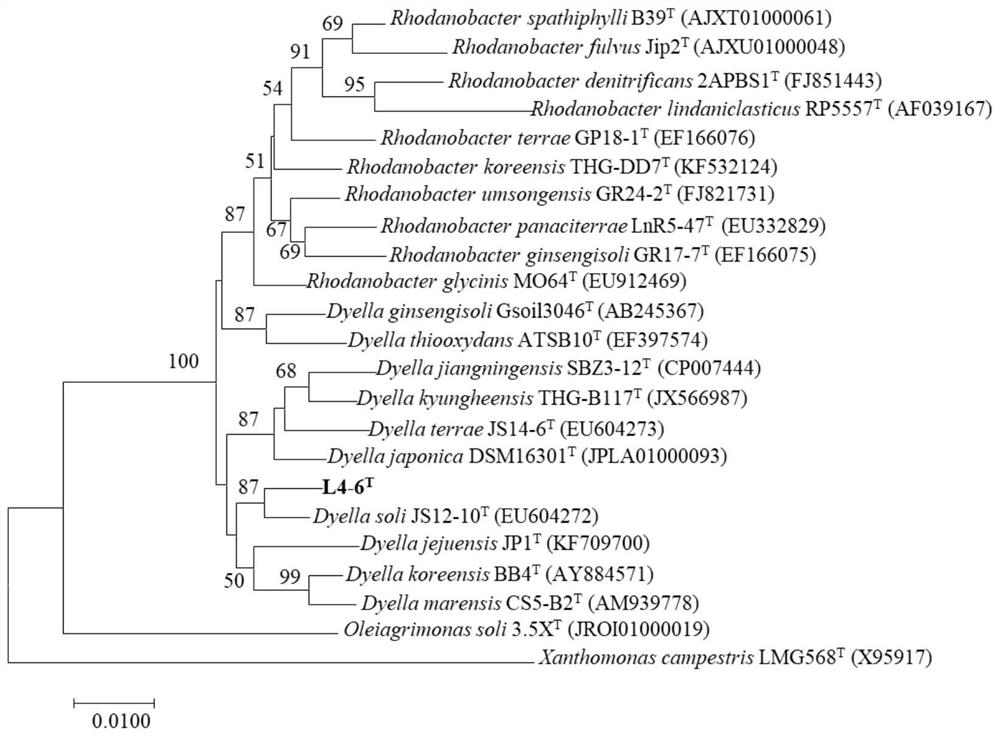

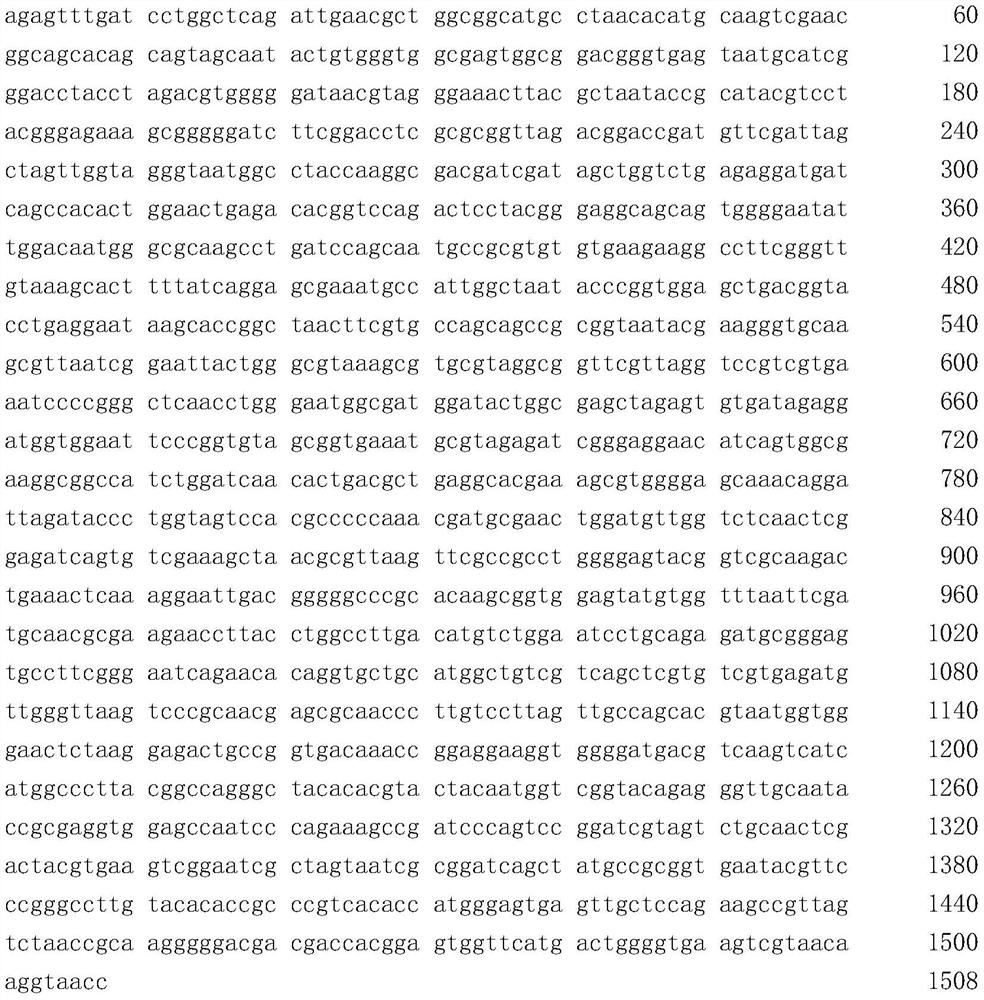

[0041] 1. Isolation, cultivation and identification of Tobacco Solanum Daiia L4-6

[0042] 1.1 Isolation of Tobacco Soil Daeella L4-6

[0043] Tobacco soil samples were taken from the tobacco planting base in Kunming, Yunnan, sealed in plastic bags, and stored at 4°C for later use. Accurately weigh 10g of soil sample, add 90mL of sterile water, shake on a shaker at 30°C and 180rpm for 30min; dilute the concentration to 10 with sterile water -1 、10 -2 、10 -3 、10 -4 、10 -5 Take 0.2mL of the five concentrations of bacterial solution and spread it on the LB plate medium, set up three parallel experiments for each concentration of the bacterial solution, cultivate it at 30°C for 48 hours, and pick it from the plate of each soil sample For different single colonies, after purification on LB plate medium, 20% of the bacterial volume was added to glycerol, and stored in a -80°C refrigerator for later use.

[0044] The isolated microorganisms were respectively inoculated in LB li...

Embodiment 2

[0060] 1. Cultivation of Tobacco Soil D. L4-6

[0061] (1) Test tube slant culture

[0062] Slope preservation medium is used, the medium is R2A agar medium, and the formula of the medium is: 0.5g of glucose, 0.5g of yeast extract, 0.5g of peptone, 0.5g of acid hydrolyzed casein, 0.5g of soluble starch, and 0.3g of sodium pyruvate , dipotassium hydrogen phosphate 0.3g, magnesium sulfate 0.05g, agar 15g, distilled water to 1000mL, pH7.2. Sterilize the culture medium at 121°C for 25 minutes, place it on a slant, inoculate it with the strain L4-6 of Agrobacterium nicotianae, and cultivate it at 28°C for 1 week to obtain the strains in the test tube;

[0063] (2) Seed cultivation

[0064] Adopt seed medium, the formula of seed medium is: dextrin 120g, soybean powder 40g, yeast extract 2g, tryptophan 0.5g, β-alanine 5g, magnesium sulfate 0.5g, ammonium phosphate 0.2g, distilled water constant volume to 1000mL, pH7.2. Sterilize the culture medium at 121°C for 25 minutes, pick pa...

Embodiment 3

[0075] 1. The culture method of Tobacco Soil Dainella L4-6 is the same as in Example 2.

[0076] 2. Fermentation of walnut shells

[0077] Weigh 600g of walnut shells pre-balanced to a moisture content of 12%, spray 120mL of the inoculum of Agrobacterium nicotiana L4-6, and put the treated walnut shells into a constant temperature and humidity box at 22°C and 60% for fermentation for 72 hours.

[0078] 3. Carbonization of fermented walnut shells

[0079] Put the fermented walnut shells into the carbonization furnace, gradually raise the furnace temperature to 80°C, and keep it for 60 minutes. After the fermented walnut shell samples are dried, quickly raise the temperature to 180°C, and keep it for 2.5 hours. After checking the degree of carbonization, turn off the heat source. The fermented carbonized walnut shell samples were taken out for later use.

[0080] 4. Preparation of fermented carbonized walnut shell particles

[0081] Take the fermented carbonized walnut shell,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com