Preparation method of Ag induced inverse opal TiO2 homojunction photocatalyst

A photocatalyst and inverse opal technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of irregular sample morphology and cumbersome steps, etc. The preparation process is simple and novel, the raw materials are cheap and easy to obtain, and the photocatalytic performance is enhanced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

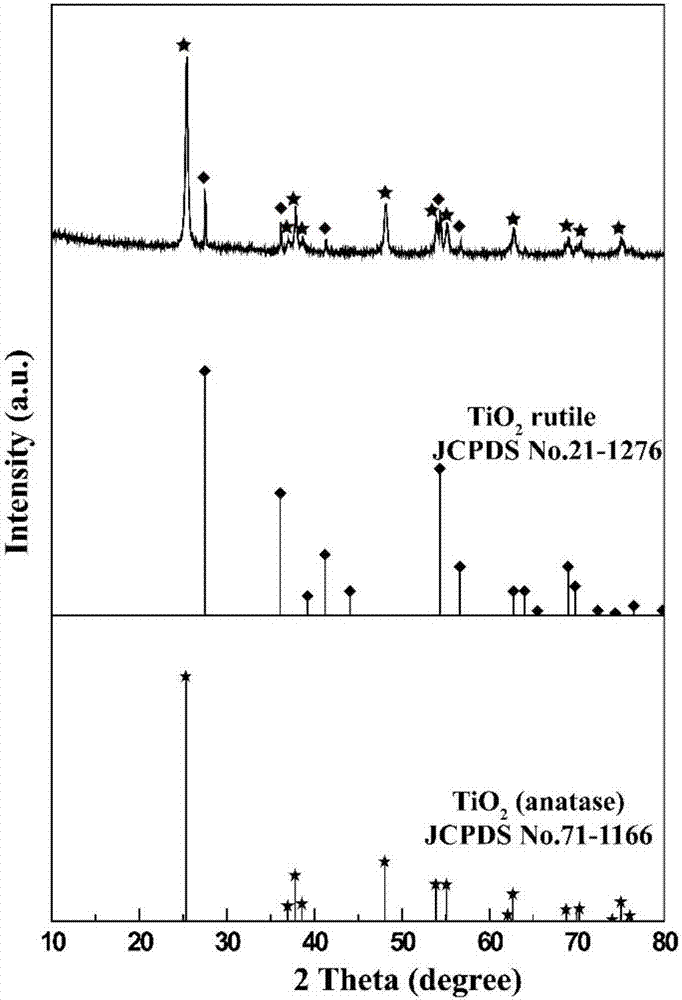

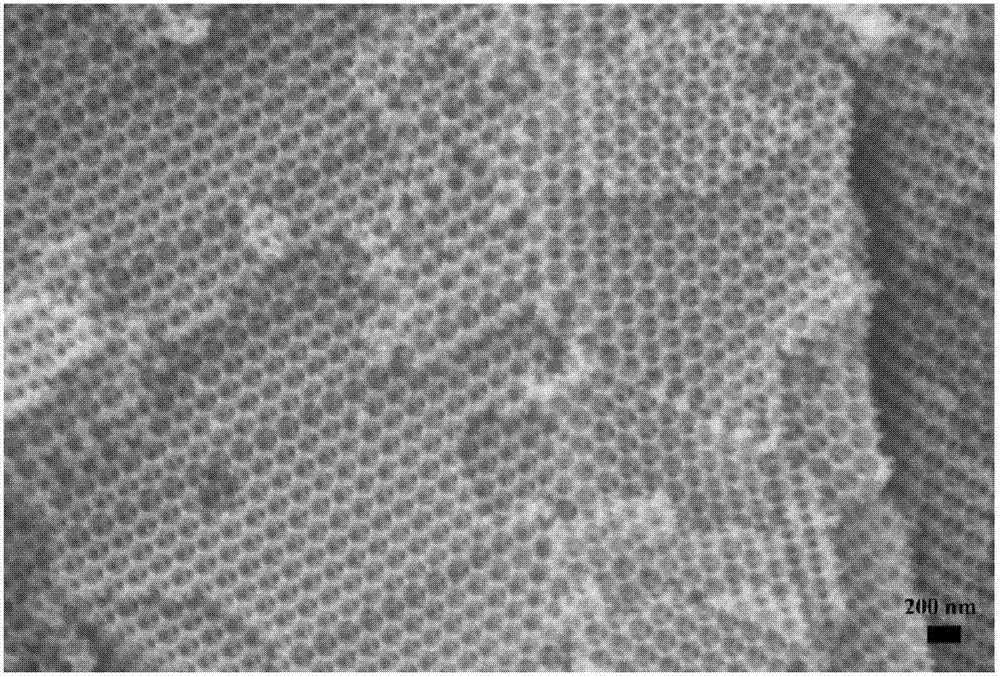

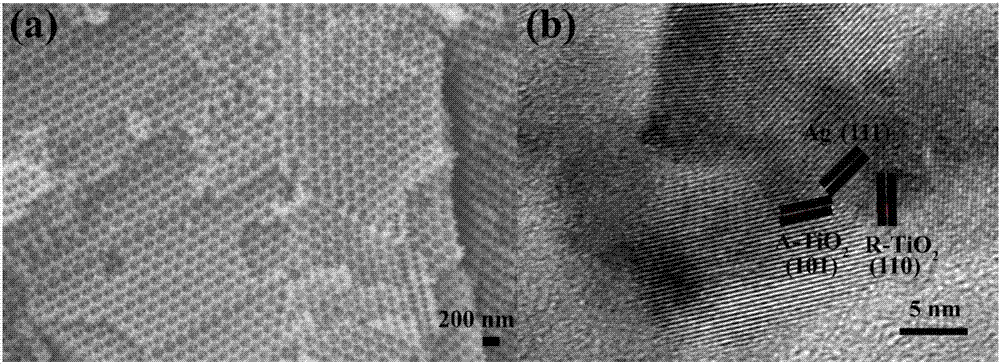

[0017] Example 1: Ag-induced inverse opal TiO 2 The preparation method of the homojunction photocatalyst adopts the following technical scheme:

[0018] Dissolve 13.5mL of styrene and 0.7g of polyvinylpyrrolidone in 100mL of deionized water, stir for 15 minutes, add 0.15g of potassium persulfate and 0.3g of silver nitrate, pass nitrogen gas for 30min to remove the air, then raise the temperature to 70°C for 24 hours. After the reaction, insert a clean glass piece into the aqueous solution containing PS spheres, and place it in a drying oven at 45°C for 4-7 days to evaporate naturally. 10 mL of butyl titanate was dissolved in 10 mL of absolute ethanol, and then 1 mL of nitric acid was added. After stirring for 1 hour, the glass sheet with PS spheres was immersed in butyl titanate solution, and after soaking for 30 minutes, the glass sheet was taken out and dried under natural conditions for 1 hour. The dried glass piece was placed in a tube furnace, raised from room temperatu...

Embodiment 2

[0019] Example 2: Ag-induced inverse opal TiO 2 The preparation method of the homojunction photocatalyst adopts the following technical scheme:

[0020] Dissolve 13.5 mL of styrene and 0.7 g of polyvinylpyrrolidone in 100 mL of deionized water, stir for 15 minutes, add 0.2 g of potassium persulfate and 0.4 g of silver nitrate, pass nitrogen gas for 30 min to remove the air, then raise the temperature to 70°C for 24 hours. After the reaction, insert a clean glass piece into the aqueous solution containing PS spheres, and place it in a drying oven at 45°C for 4-7 days to evaporate naturally. 10 mL of butyl titanate was dissolved in 10 mL of absolute ethanol, and then 1 mL of nitric acid was added. After stirring for 1 hour, the glass sheet with PS spheres was immersed in butyl titanate solution, and after soaking for 30 minutes, the glass sheet was taken out and dried under natural conditions for 1 hour. The dried glass piece was placed in a tube furnace, raised from room temp...

Embodiment 3

[0021] Example 3: Ag-induced inverse opal TiO 2 The preparation method of the homojunction photocatalyst adopts the following technical scheme:

[0022] Dissolve 13.5mL of styrene and 0.7g of polyvinylpyrrolidone in 100mL of deionized water. After stirring for 15 minutes, add 0.3g of potassium persulfate and 0.5g of silver nitrate. After purging the air with nitrogen for 30 minutes, raise the temperature to 70°C for 24 hours. After the reaction, insert a clean glass piece into the aqueous solution containing PS spheres, and place it in a drying oven at 45°C for 4-7 days to evaporate naturally. 10 mL of butyl titanate was dissolved in 10 mL of absolute ethanol, and then 1 mL of nitric acid was added. After stirring for 1 hour, the glass sheet with PS spheres was immersed in butyl titanate solution, and after soaking for 30 minutes, the glass sheet was taken out and dried under natural conditions for 1 hour. The dried glass piece was placed in a tube furnace, raised from room ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com