Preparation method of biodegradable hydrogel scaffold material for cardiac repair

A technology of biodegradable scaffold materials, applied in the field of preparation of hydrogel scaffold materials, can solve the problems of immune rejection, insufficient donor organs, etc., and achieve good biocompatibility, low curing shrinkage rate, and good degradation performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The steps of a preparation method of a biodegradable hydrogel scaffold material for heart repair are as follows:

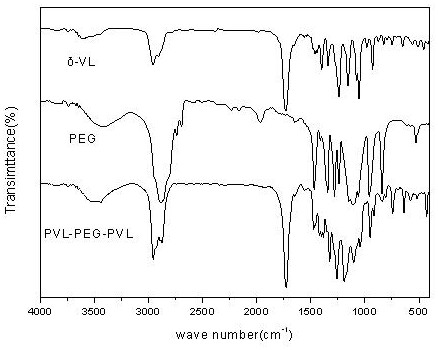

[0031] 1) Preparation of polyvalerolactone-polyethylene glycol-polyvalerolactone (PVL-PEG-PVL)

[0032] a. Weigh 2g of polyethylene glycol (PEG) (without water) and 4mL of δ-valerolactone (δ-VL) (without water) into the test tube and stir evenly, then add 0.138g of catalyst stannous octoate and stir well ;

[0033] b. Vacuumize the reaction system for 10 minutes to remove moisture and oxygen in the reaction system, and react the sealed system at a temperature of 120°C for 14 hours;

[0034] c. Dissolve the product obtained from the reaction in dichloromethane (DCM) and ultrasonically remove the bubbles in the solution, move the solution to a mold to remove the dichloromethane (DCM), and make the product into a film (PVL-PEG-PVL three-embedded Segment copolymer) for use.

[0035] 2) modified

[0036] a. In a dry round-bottomed flask under the protection ...

Embodiment 2

[0042] The steps of a preparation method of a biodegradable hydrogel scaffold material for heart repair are as follows:

[0043] 1) Preparation of polyvalerolactone-polyethylene glycol-polyvalerolactone (PVL-PEG-PVL)

[0044] a. Weigh 2g of PEG (PEG) (water removed) and 4mL of δ-valerolactone (δ-VL) (water removed) into a test tube and stir evenly, then add 0.021g catalyst stannous octoate and stir evenly;

[0045] b. Vacuumize the reaction system for 10 minutes to remove moisture and oxygen in the reaction system, and react the sealed system at a temperature of 130°C for 15 hours;

[0046] c. Dissolve the product obtained from the reaction in dichloromethane (DCM) and ultrasonically remove the bubbles in the solution, move the solution to a mold to remove the dichloromethane (DCM), and make the product into a film (PVL-PEG-PVL three-embedded Segment copolymer) for use.

[0047] 2) modified

[0048] a. In a dry round-bottomed flask under the protection of nitrogen, dissolve...

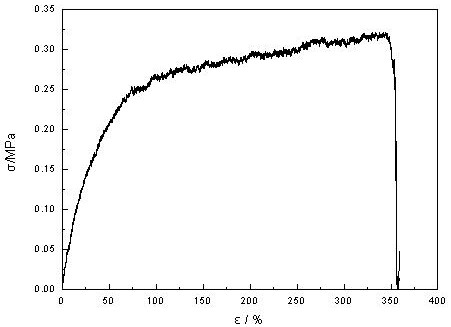

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com